Ji nan keysong machinery co.LTD |

|

Stainless Steel Feed Pellet Machine , Chicken Feed Processing

Machine

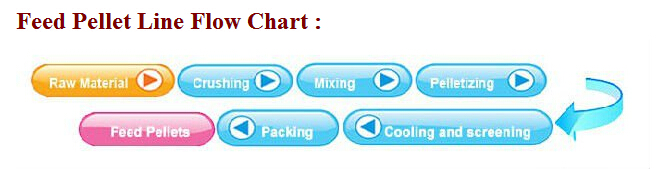

1. Feed pellet flow chart:

2. Feed Processing Machine data:

Model | KS250 | KS320 | KS350 | KS400 | KS420 | KS508 |

Main Motor Power (kw) | 22 | 37 | 55 | 90 | 110 | 160 |

Conditioner Power (kw) | 1.5 | 2.2 | 2.2 | 3 | 5.5 | 7.5 |

Dia of mould (mm) | 250 | 320 | 350 | 400 | 420 | 508 |

Feeder Power (kw) | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

Size of Finished pellets (mm) | 1.5-12 | 1.5-12 | 1.5-12 | 1.5-18 | 1.5-18 | 1.5-18 |

Yeild (t/h) for animal feed | 1-2 | 2-4 | 2-6 | 3-8 | 4-12 | 4-18 |

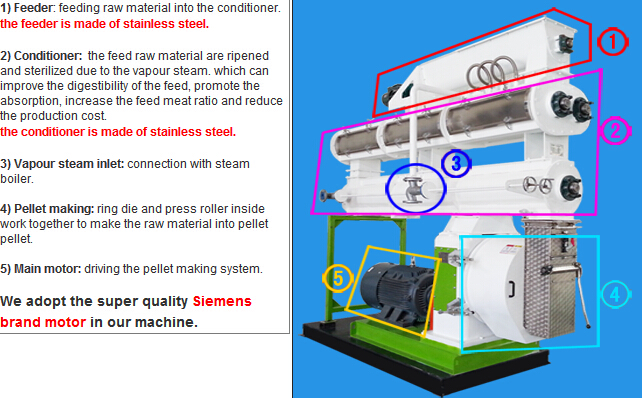

3. Feed Processing Machine:

The feed pellet mill belongs the extruding machine,it can extrude all kinds grain/biomass into pellet ,then feed to animal,poultry,,bird,dog,pig,chicken etc,the raw material can be different grain,

such as wheat,corn,soybean,soyabean meal,etc,all most all the grain into pellet directly without any Adhesive materials,but the raw material size should less than 1-5mm with moisutre 8-15%.

widely used to manufacture pellets for animal feed including fish

food (aquafeed) from prepared feedstock grains (barley, corn,

malt, oats, soybean, etc.). Production volume of pellets per pellet

mill can range from 500 kg/h to 20 t/h.

5. Advantages:

1) Feeder is variable speed controlled to meet different outputs

requirements;

2) It is equipped with magnet and over load protection system, which

can protect machine well during production;

3) Double jacketed conditioner can extend the time of material cooking

and gelatinization to enhance conditioning effect;

4) It can be equipped with one, two, three or more layers of jacketed

conditioner.

5) Can be equipped with double-layer, three-layer folder conditioner

or double shaft track conditioner, to meet the different needs of

producing high grade livestock and poultry feed and aqua-feed.

After-sale services:

Provide considerate services to minimize clients’ worries.

(1) Assist clients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(4) Examine the equipment regularly;

(5)Take initiative to eliminate the troubles rapidly at site;

(6) Distribute the guarantee fittings door-to-door;

(7) provide perfect service;

(8) Provide technical exchanging;

(9) Provide maintenance for big items.