Xi'an Kacise Optronics Co.,Ltd. |

|

Verified Suppliers

|

|

Kacise KS3ARGA1 Series

The KS3ARGA1 series , a product of innovation by Kacise, offers a state-of-the-art solution for measuring three-dimensional angular velocities. This triaxial universal angular rate gyro leverages advanced MEMS technology to deliver high performance metrics that are essential in today’s precision-oriented environments.

Technological Edge

Each axis within this three-axis gyro system is built using a highly sophisticated MEMS technology chip. This core technology ensures top-tier performance, maintaining a balance between being economical and providing the necessary reliability. Durability is also a significant aspect of the KS3ARGA1 series, with a robust package design engineered to withstand demanding conditions. Moreover, it comprises an intrinsic Self-Test functionality to ensure consistent and reliable performance.

Operational Principle

The operational prowess of the KS3ARGA1 gyros is grounded in the resonator gyro principle. Integral to this system are dual polysilicon sensitive structures, each featuring a high-frequency vibrating frame. These frames are powered through electrostatic force, causing them to resonate, and thus embody the crucial components of velocity calculation. Adjacent to the frames, capacitance-sensitive structures capture the Coriolis force that arises with angular motion. This force is then converted into an electrical signal. Subsequent amplification and modulation stages refine this signal, finally producing an output directly proportional to the measured angular rate.

● low power consumption

● wide operating temperature range

● wide bandwidth

● small size

● DC input DC output

● fast start

● high performance, low cost

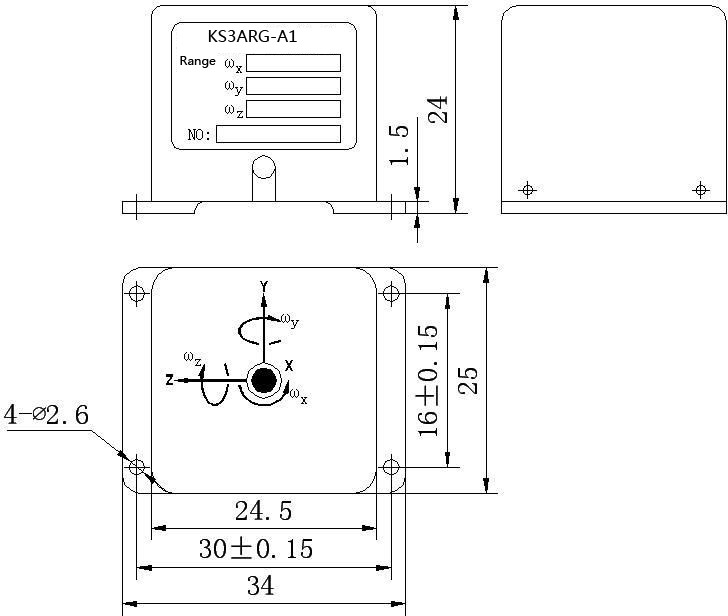

Dimensions

| Parameter | KS3ARGA1 |

| Power supply parameter | |

| Input voltage | 6-15V(Vdc) |

| Incoming currentmA | <30 mA |

| Offset voltage | 2.5±0.05(V) |

| Output voltage | 0.5-4.5(V) |

| Product performance | |

| Range | ±250(°/s) |

| Scaling factor | 8±0.5(mv/°/s) |

| Nonlinearity | ≤0.05(%FR) |

| Resolution/Threshold | ≤0.1(°/s) |

| Cross coupling | ≤2(%) |

| Output noise | <0.02(°/s√Hz) |

| run-up time | ≤20(ms) |

| Bandwidth can customize | 80(Hz) |

| G-value sensitivity | <0.02(°/s/g) |

| Mean time between failures | 100000hour(MTBF) |

| Size | 34×25×24(mm) |

| Weight | ≤40(g) |

| Environment | |

| Operating temperature range | -45~+80(°C) |

| Storage temperature | -65~+125(°C) |

| Tolerated acceleration | 20000(0.1ms)(g) |

The attitude reference system represents a cornerstone of both aviation and maritime operations. By providing precise information about an object's orientation in space, these systems enable accurate navigation and alignment, which is essential for the safe maneuvering of airplanes and ships. Without a reliable attitude reference system, maintaining the correct heading and pitch would be significantly more challenging.

Platform stabilization technology is another crucial development that spans across various fields. Its primary purpose is to ensure a stable platform for equipment that is sensitive to movements or vibrations. This includes everything from telescopic sights on military vehicles to sophisticated scientific instruments used in research. By isolating the equipment from external disturbances, platform stabilization ensures that precision and accuracy are maintained.

In the world of robotics, stabilization is just as important. Robots often perform tasks that require a high degree of control and stability, whether it's precision assembly in manufacturing or traversing uneven terrain in exploration missions. Similarly, antenna stabilization is key for maintaining clear communication signals, especially in mobile applications such as satellite news gathering or maritime communications, where steady signal reception is mission-critical.

Lastly, the gyro stabilization technology has found a new wave of popularity in the field of photography and videography. With the advent of high-resolution cameras and digital cameras, gyros are increasingly being used to stabilize images and videos. This not only eliminates the blurriness caused by hand movements but also allows for smoother panning and tilting, resulting in professional-quality content.

As we continue to innovate, the applications of stabilization technology will undoubtedly expand, permeating even more aspects of our daily lives and advancing the boundaries of what's possible.

Our Electronic Gyroscope Sensor is designed to provide precise motion sensing in a variety of applications. Our product technical support and services are dedicated to ensuring that you can integrate and use our gyroscope sensor effectively in your projects.

Technical Support:

- Comprehensive online documentation: Access detailed product specifications, integration guides, and troubleshooting articles to assist you with any technical queries regarding our Electronic Gyroscope Sensor.

Services:

- Email support: Reach out to our dedicated support team for personalized assistance with any technical issues you may encounter.

We are committed to providing you with the support you need to utilize our Electronic Gyroscope Sensor to its fullest potential.

Product Packaging:

The Electronic Gyroscope Sensor comes securely packaged in an anti-static bag to prevent any electrostatic discharge during handling. The bag is then placed in a custom-fit foam insert that snugly holds the sensor in place, ensuring maximum protection against physical shocks and vibrations. This foam is encased in a sturdy cardboard box which is sealed and labeled with the product information and handling instructions. The packaging has been designed to be compact while offering the best possible protection for the sensitive electronics inside.

Shipping:

Once the Electronic Gyroscope Sensor is packaged, it is ready for shipping. The boxed product is placed in a secondary, larger cardboard box with additional cushioning material to fill any void space, minimizing movement during transit. Fragile stickers are applied to the outer box to alert couriers that the contents require careful handling. The package is then sealed with heavy-duty packing tape and dispatched using a reliable shipping service that provides a tracking number. Customers will receive their tracking information via email to monitor their package's journey until delivery.