Xi'an Kacise Optronics Co.,Ltd. |

|

Verified Suppliers

|

|

KLD805 80G FM Radar Level Sensor

Introduction

The Difference In Application Of Radar Level Transmitter Frequency

Range

Dirty and polluted environment

With long-term use, dirt and pollutants accumulated on the antenna will affect the strength and direction of the radar signal. For high frequency signals, any dirt that covers the antenna will absorb more energy, and the direction of the beam may change. This results in a loss of signal strength. So, low-frequency and medium-frequency technologies are more suitable.

Storage tanks with condensate and/or steam

Condensation and steam can cause reflections on product surfaces to be masked by the “noise” of water droplets. This is more of a problem for high frequency signals. So mid and low frequency techniques are a better choice. Antennas with flat, horizontal surfaces should always be avoided for condensation.

High steam and agitation

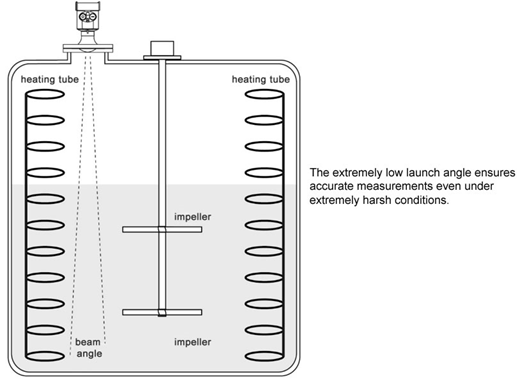

Be sure to choose the 80G millimeter-wave radar level meter. The 80G radar level meter has a high transmission frequency and has good penetration and is not affected by steam. The 2° transmission angle can effectively avoid the interference of the stirring blade. The unique echo Tracking algorithm avoids reading multiple echoes when the material level is high.

Applications with turbulence, waves and ripples

Waves and ripples are often found on the surface of process liquids in large tanks. And this turbulence is especially detrimental to high-frequency measurements. Low and mid frequency level instruments emit longer wavelengths, making them perform better.

Foam application

Like dust and condensation, a layer of foam on top of the liquid can absorb the radar signal, making accurate measurements more difficult. Low frequencies work best with thick foams, such as beer, molasses, or latex. For lighter foam, the mids perform well. High frequency techniques should be avoided in foam applications.

KLD805

| Medium: strong corrosive liquid, steam, foam, high temperature. and high pressure Measuring range: 0.1m~10/20/30/60/100m Process connection: flange ≥ DN80 Process temperature: -40~200℃ Process pressure: -0.1~2.5MPa Antenna size: 76mm lens antenna (according to flange size) Antenna material: PTFE/overall filling Accuracy: ±1mm Protection class: IP67 Center frequency: 80GHz Launch angle: 3° Power supply: two-wire /DC24V four-wire /DC12~24V four-wire /AC220V Casing: aluminum / plastic / stainless steel Signal output: two-wire /4...20mA/HART protocol four-wire 4...20mA/ RS485 Modbus |

Installation

Installation Requirements

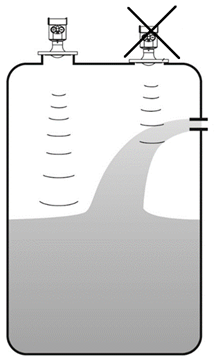

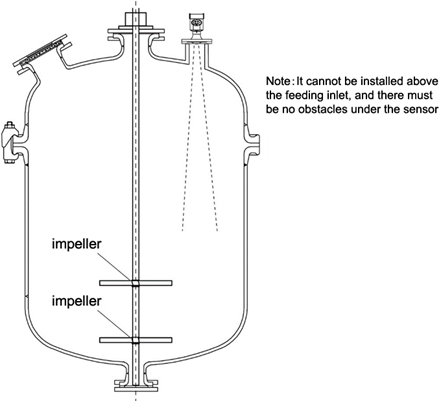

When installing the instrument, avoid installing it above the material inlet, and try to avoid various objects that affect the signal, such as stirring paddles, etc.

Under extremely complex working conditions, the instrument can work normally if there is no obstacle in the area with a radius of 20cm centered on the installation point.

Installation connection diagram:

The maximum installation spool height H max depends on the installation spool diameter D and the size of the product launch angle.

Too long installation connection will affect the radar performance.

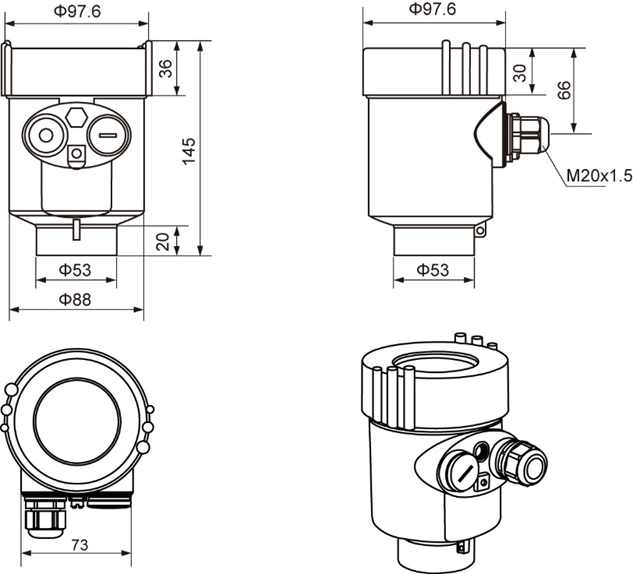

Dimensions

Casing Dimension

Unit in mm:

Production: