Changsha Honway Machinery Co., Ltd. |

|

Concrete Scarifier Machine With Carbide Milling Cutter For Foad Scarifier

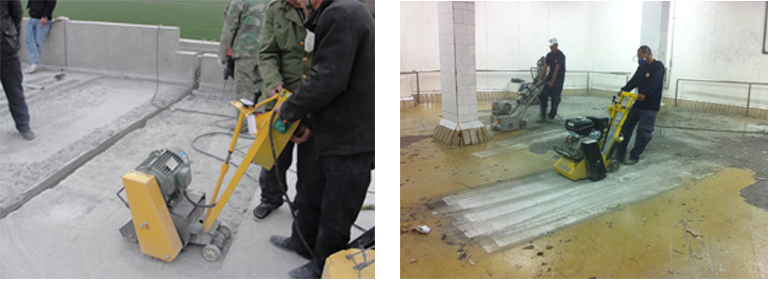

Floor scarifier, also called floor plane, is used for creating grooves in concrete surfaces and removes paint or coatings and to clean and prepare concrete surface prior to coating and floor covering. HWS200 rotates with blunt or flat TCT cutter, in high speed, to chip away the surface of concrete, asphalt, and epoxy. Quick-change drum design allows you change cutters in minutes.

Parameters:

| Model | HWS200 | HWS200E |

| Power OPtion | 9HP Honda Engine | 5.5KW Motor for 380V,3P |

| Working Width | 200mm | 200mm |

| Working Depth | 1-3mm | 1-3mm |

| Drum Rotation | Down cut(clockwise) | Down cut(clockwise) |

| Drum Assembly | Changeable | Changeable |

| Depth Control | Yes | Yes |

| Num of Shaft | 6pcs | 6pcs |

| Num of Cutter | 78pcs | 78pcs |

| Machine Weight | 105KG | 120KG |

| Packing Size | 1100*530*970mm | 1100*530*970mm |

| Walking Way | Push model | Push model |

Application:

Remove concrete floor for new layer.

Remove epoxy coatings, thermoplastic coatings, paint and traffic line;

Asphalt/cement surface galling

Level uneven surfaces and trip hazards;

Features

Drum is heat treated specially;

Special heat treatment for the drum, shafts, and cutters

Change the drum assembly in a few minutes

Shockproof handle for the comfortable and long lasting operation

Front mounting lifting handle for easy transportation

Good quality bearing

Product Details

4, Good quality bearing and bearing assembly.

High performance tungsten carbide tipped cutter is used for grooving roughening, and leveling the epoxy, concrete and asphalt floor, to creat a rough floor or remove the floor coating; tips are inserted into the steel base, which is more economic in price, but still effective in work.

The material of cutter base is 45crmo

Tungsten and cobalt material are from good brand mining company

The technique of high frequency welding guarantees the welding qualityo

Mold stamp is used for keeping the exact size for every cutter.

Variable size is available for different size of scarifying machine

Why the bearing of floor scarifier needs to grease within a few hours?

The working site for floor scarifier is very bad, even if with the

vacuum Unlike the floor grinding machine, the bearing of floor

scarifier is exposed to abundant dust, Grease could prevent dust

and lubricateThe broken of bearing, in many cases, is not caused by

the quality ofbearing, but the usage habit. Grease must be given

Every machinehas a grease gun when it leaves factory.

Closer Look

Construction

Company introduction

Changsha Honway Machinery Co., Ltd is the Professional manufacturer for floor scarifying & grinding & polishing machine in China. Our company is well equipped with CNC machine for mechanical treatment and gear hobbing machines for gear processing. We are proud of having a team of experienced technicians and workers. All of the products are CE certified and comply with international standard. The products are already exported to 20 countries and got the good reputation.

After Sell Service

1. One year of warranty for machine.

2. In the warranty period, the spare parts are sent by DHL, which is paid by Honway Company.

3. Out of warranty period, the spare parts are sent by DHL, which is paid by customer.

4. Honway always store the spare parts of old models, in case that the machine needs repair in future.

5. Our strong R&D department offers technology support within 8 hours.

6. Topwell care service will follow you and your machine for years.

FAQ

Q:What is the working depth and working width of HWS200?

A: The working depth is 0-5mm, which also depends on the floor condition. The working width is 200mm.

Q: As the cutters on the drum are 78pcs, is it enough for milling floor?

A: Usually it is enough, most of our customers use 78pcs; If you think it is not enough, we could add to 96pcs.

Q: What is the lifetime of the TCT cutters?

A: To be honest, it is hard to give a data of lifetime. It is because the floor condition varies different.