RUIAN BEST MACHINE CO., LTD |

|

Allfine Group-20 years experience Solution

1:Label production line- flexo print machine,die cutting

machine,slitting machine,inspection and rewinding machine

2:Flexible package line-water bottle label PVC,heat transfer Pet,

Opp, Pe etc rotogravure printer, dry laminator, PP PE film blowing

machine,bag making machine

3:Decal paper,wine and smoking package-Silk screen press machinery,

wicket dryer, uv dryer

4:Paper cup production line- flexo printer. die cutting machine,

paper cup making machine

1: Save material 2: Improve efficiency 3:Professional tranning 4: Factory built

Partner Manager-Jack Huang

Allfine Group

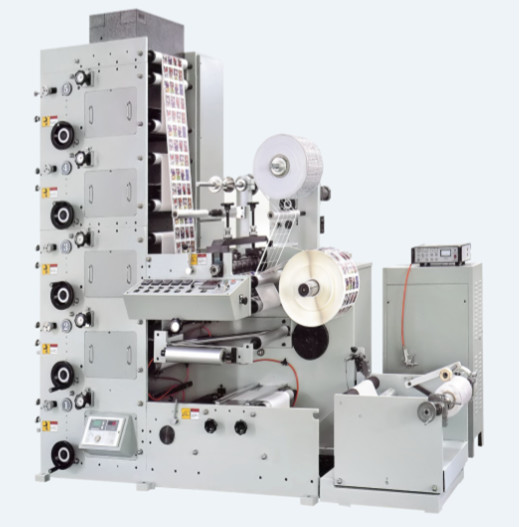

820 Good Quality New Automatic Label/ Paper Cup Flexo Printing Machine Made in China

flexo printing production line.pdf

Performance and characteristics:

1.The main motor adopts imported frequency conversion stepless

speed regulation. Discharge and receiving are controlled by

magnetic powder brake and clutch (or optional Japanese MITSUBISHI

antomatic tension controller.)

2.The feeding device is controlled by the automatic deviation correcting sensor.

3.The ceramic anilox roller, has the characteristics of long service life, wear resistance, corrosion resistance. To reduce the frequency of replacing the roller, improve the printing efficiency favoourable.

4.The printing units are equipped with a group of infrared drying device.

5.Each printing unit infrared drying device interchangeable UV drying device.

6.The rooling device adopted clipping device with air expansion core shaft.

7.The printing unit adopts 360 degree circumferential plate adjustment. Each printing unit can independently gear or release, so that other units continue printing.

8.The roll feeding, printing, polishing, auto infrared drying. Laminating and rewinding a continuity.

9.The product has a wide range of printing, humor and no pollution. The characteristics and the economic benefit is high, fast printing speed etc. is the printing machine paper, cardboard, high-grade self-adhesive trademark ideal for the printing plant.

10.When the roller automatic parking detachment, and low speed rotation, to prevent dry ink.

Technical data:

| Model | 320 | 420 | 520 |

| Max Printing speed | 100m/min | 100m/min | 100m/min |

| Printing color | 1-12colours | 1-12colours | 1-12colours |

| Max. width of paper | 350mm | 450mm | 550mm |

| Max .printing width | 320mm | 420mm | 520mm |

| Max. unwinding diameter | 650mm | 650mm | 650mm |

| Max. rewinding diameter | 650mm | 650mm | 650mm |

| Printing length | 175-381mm | 175-381mm | 175-381mm |

| Precision of chromatography | ±0.1mm | ±0.1mm | ±0.1mm |

| Dimensions | 2m*1.0m*2.2m | 2m*1.1m*2.2m | 2m*1.2m*2.2m |

| Machine weight | About 2600kg | About 2800kg | About 3000kg |

HD video link about LC 420 Flexo Label Printing Machine printing

paper cups with In mold die cut station and UV dryers

https://youtu.be/SG_vbjCp8L0

video link: label flexo printing machine 5 colors, dual banks ovens

https://www.youtube.com/watch?v=Z9Mxd9PtAec

video link: LC adhesive label flexo printing machine 320mm 5color

https://www.youtube.com/watch?v=s3fnEjgIoPU

5colors 320mm width flexo printing machine for silver subunit paper

https://youtu.be/LM21RhG9s7c

Unwind and infeed section – The roll of stock must be held under

control so the web can unwind as needed.

Printing section – Single color station including the fountain,

anilox, plate and impression rolls.

Drying station – High velocity heated air, specially formulated

inks and an after-dryer can be used.

Outfeed and rewind section – Similar to the unwind segment, keeps

web tension controlled.

1. Fountain roller

The fountain roller transfers the ink that is located in the ink

pan to the second roller, which is the anilox roller. In Modern

Flexo printing this is called a Meter or "metering" roller.

2. Anilox roler

This is what makes flexography unique. The anilox roller meters the

predetermined ink that is transferred for uniform thickness. It has

engraved cells that carry a certain capacity of inks that can only

be seen with a microscope. These rollers are responsible to

transfer the inks to the flexible-plates that are already mounted

on the Plate Cylinders.