Carton Box Manufacturing Machine 300 Sheet/Min Flexo Printing

Slotting Machine

High Efficiency Carton Box Manufacturing Machine Flexo Folder

Gluer Flexo Printing Slotting Machine for All Carton Making

Easy to Set-up from South of China

SUMMARY OF MACHINE

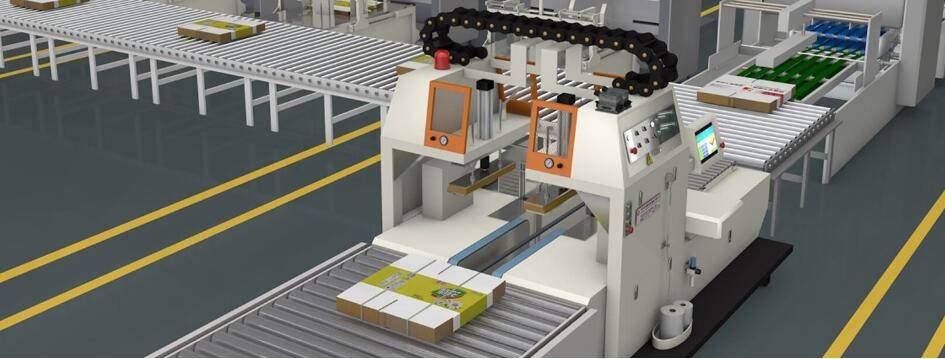

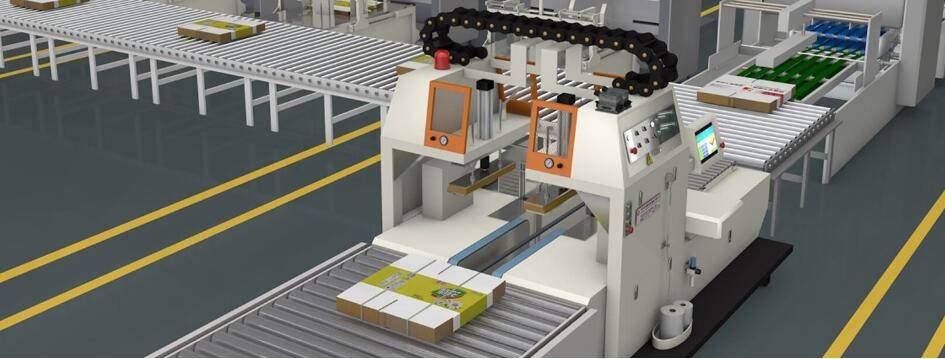

- Bellow show the compelet solution of Carton Box Making from

Cardboard to Boxes by Full automatic ways, consists of a Automatic

or Semi-automatic Pre-feeder, Flexo Folder Gluer FFG's

(Case Maker), Automatic PP/PE Strapping Machines, after cardboard

pass through these machine, can be dispatch to customer directly.

- The TP-CR Series Flexo Printing Slotting Die-cutting Machine is a

high-end High Quality Printing RDC machine, with Register Servo

Drive, this Top printing Machine with Vacuum Transfer provides an

excellent print registration, slotting and die-cutting results at

high speed, greatly increase your production capacity.

- This machine can easy match with Automatic or Semi-auto Pre-feeder,

FFG's, Automatic Vibrator and Counter Stacker, or Automatic PP/PE

Strapping Machine according to your needs.

The main features of this machine is Fast Order Change (new order

change time 15 mines, Printing Plate change time 40 seconds.),

Accurate Order Change, only need 1-2 cardboard for machine

adjusting, then can get into normal production, greatly save your

material cost and time. - Independent Industrial Computer System can connect with Corrugated

Line ERP System, you can check the production any time in your

central control house.

Specification

| Model | TP-CR-0920 | TP-CR-1224 |

| Size | 0920 | 1224 |

| Max.Sheet Size (FxA) | 890x2000 | 1190x2400 |

| Skip Feed Size (FxA) | 1200x2000 | 1400x2400 |

| Min.Sheet Size (FxA) | 280x700 | 350x720 |

| Max.Printing Area (FxA) | 890x1960 | 1190x2360 |

| Top Speed(Sheet/min) | 300 | 250 |

| Economic Speed (sheet/min) | 150-250 | 120-220 |

| Min. Slotting Space-Reverse Knife (BxCxBxC) | 270x100x270x100 | 270x100x270x100 |

| Min. Slotting Space-Normal Knife (BxCxBxC) | 160x160x160x160 | 160x160x160x160 |

| Max. Slot Depth Size | 250 | 320 |

| Min. Box Height Size | 110 | 110 |

| Max. Die-Cutting Area | 850x1950 | 1150x2350 |

| Sheet Thickness | 1.5-11 | 1.5-11 |

| Thickness of Printing Plate | 7.2 | 7.2 |

AUTOMATIC PRE-FEEDER

- Pre-feeder is used to connect with automatic flexo printer machine.

- Conveyor arm length is motorized and adjusted freely.

- Back squarer is automatic along with conveyor.

FLEXO PRINTER SLOTTER FOLDER GLUER

Feeding Unit

- Lead edge feeder with vacuum absorber.

- Upper Dust remover with brushers

- Sheet transfer with rubber pull rolls.

- Gap of feeding rollers, Side baffles are computerized with order

managing.

Printing Unit

- Sheet transfer with vacuum box.

- Anilox roller with rubber roller inking or Anilox roller with

Chambered doctor blade system for choosing.

- Quick replacing of rubber roller.

- Gap of anilox roller, printing drum, vacuum box and horizontal and

vertical movement are computerized with order managing.

Slotting Unit

- Sheet transfer with rollers.

- 8-shafts rotation: Pre-creasing, Dual-Creasing, Single shaft

slotting.

- All slotting knife holders connect with creasing rings and slotting

knifes, synchronously moving in horizontal position.

- Gaps of creasers and slotting knifes, box height, registering and

vertical moving are computerized with order managing.

Die cutting Unit

- Sheet transfer with rollers.

- Upper die cutting rubber roller is driven by independent frequency

converter for line speed compensation.

- Shaft-head treated with lock, not welding, given strong capacity of

bearing pressure.

- Gaps of feeding, registering and vertical moving are computerized

with order managing.

FFG- Folder Gluer & Counter Ejector

- Top loading type Counter Ejector.

- Rolling wheel or auto flexo gluing system for choosing.

- Adjustment with servo motors.

- Gaps of Hold-Arm, Glue head and conveyor bracket are computerized

with order managing.

- Central computer system controls whole units of machine.

AUTOMATIC PE STRAPPING MACHINE

- Automatic pe strapper

- Cartons transferred by rolling wheel.

- Size Change automatically

- Integrated lubrication

- Strapping materials PE.

ADVANTAGES

- High capability: Maximum output up to 15000 per hours

- Labor saving: 3-4 workers for whole processes, to match with Auto

Strapping machine.

- Easy Job: Order saving and quick changing by 5-10 min.

- Wide range application: Be used to agriculture, food, logistics and

industrial packaging.

- Acceptability in Precision: More than 99% for printing accuracy and

Up-Fold gap.

- Control with 9 sets of Servo Motor, Bosch Rexroth Brand origin from

German.

Accuracy Assurance

| Feeding | ≤ ±1.5 mm |

| Printing(4 colors) | ≤ ± 0.5 mm |

| Slotting | ≤ ± 1.5 mm |

| Die-cutting | ≤ ± 1.5 mm |

| Up-fold gap(For FFG) | 3-layer | ≤ ± 2 mm |

| 5-layer | ≤ ± 3 mm |

| “Fishtail” issue (For FFG) | 3-layer | ≤ ± 1.5 mm |

| 5-layer | ≤ ± 2 mm |