Guangdong Toprint Machinery Co., LTD |

|

Verified Suppliers

|

Flexo Printer Slotter Machine 1200x2400mm Hot sale Corrugated Carton Box Flexo Printing Slotting Die Cutting Machine for Carton Box Making Packag Machine from China

BRIEF INTRUCTION

The Q3 featured with the functions as below marked by “√”.

| 1st Process | 2nd Process | 3rd Process | 4th Process | 5th Process |

| Order setting | Feeding | 1-6 color Printing | Slotting or Die cutting | Vibrator Cleaning |

| √ | √ | √ | √ | × |

| 6th Process | 7th Process | 8th Process | 9th Process | 10th Process |

| Vanishing | IR drying | Gluing | Stitching | Stacking |

| × | × | × | × | √ |

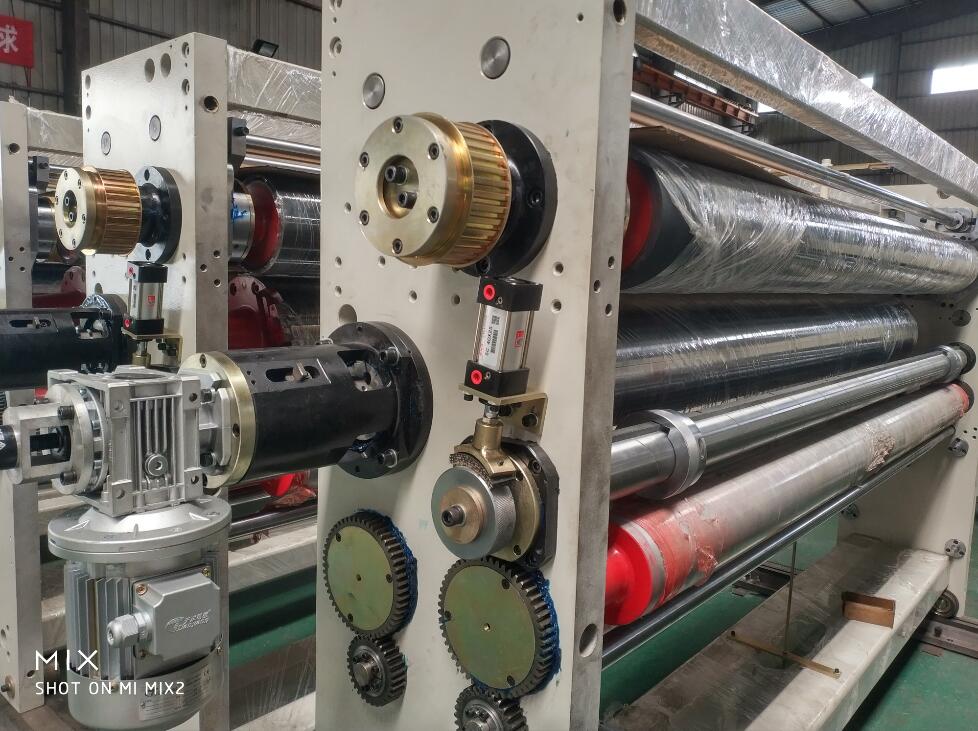

The Photo of Machine

SPECIFICATION

| Model | SP-Q3 | SP-Q3 | SP-Q3 | |

| Size | 0920 | 1224 | 1628 | |

| Max.Sheet Size (FxA) | 890x2000 | 1190x2400 | 1600x2800 | |

| Skip Feed Size (FxA) | 1200x2000 | 1400x2400 | 1800x2800 | |

| Min.Sheet Size (FxA) | 280x700 | 350x720 | 450x850 | |

| Max.Printing Area (FxA) | 890x1960 | 1190x2360 | 1600x2760 | |

| Top Speed(Sheet/min) | 300 | 250 | 180 | |

| Economic Speed (sheet/min) | 150-250 | 120-220 | 100-160 | |

| Min. Slotting Space-Reverse Knife (BxCxBxC) | 270x100x270x100 | 270x100x270x100 | 320x120x320x120 | |

| Min. Slotting Space-Normal Knife (BxCxBxC) | 160x160x160x160 | 160x160x160x160 | 160x160x160x160 | |

| Max. Slot Depth Size | 250 | 320 | 450 | |

| Min. Box Height Size | 110 | 110 | 160 | |

| Max. Die-Cutting Area | 850x1950 | 1150x2350 | 1530x2750 | |

| Sheet Thickness | 1.5-11 | 1.5-11 | 1.5-11 | |

| Thickness of Printing Plate | 7.2 | 7.2 | 7.2 | |

| Main Working Power(KW) | 4 Colors Slotter Die-cutter | 69 | 76 | 95.5 |

| Stacker + Vibrator | 3+10 | 3+10 | 3+10 | |

| Total Power(KW) | 4 Colors Slotter Die-cutter | 181.5 | 88.5 | 108 |

| Stacker + Vibrator | 3+10 | 3+10 | 3+10 | |

| Dimension (mm) | 4 Colors Slotter Die-cutter | 6600x4950x2550 | 9900x5350x2650 | 9900x5750x2750 |

| Stacker | 6500x3500x3000 | 6500x3970x3000 | 6500x4440x3000 | |

| Vibrator | 3200x3300x1100 | 3200x3700x1100 | 3200x4150x1100 | |

FEATURES

Feeding Unit

Printing Unit

Slotting Unit

Die cutting Unit

ADVANTAGES

ACCURACY

| Feeding | ≤ ±1.5 mm |

| Printing(4 colors) | ≤ ± 0.5 mm |

| Slotting | ≤ ± 1.5 mm |

| Die-cutting | ≤ ± 1.5 mm |

Following items can be featured as per actual needs.

Ceramic anilox roller

Chambered doctor blade system

IR dryer

Coated varnishing

Dual-shaft Slotting structure

Pre-feeder

Inline Folder Gluer

Non-crush wheel feeder with servo control.