Kasugai Shanghai Co., Ltd. |

|

Verified Suppliers

|

|

ASTM A182 F1 F5 F9 F11 F12 F22 F91 ANSI B16.5/B16.47 SW Alloy Steel Socket Weld Flange

Alloy steel is a type of steel alloyed with several elements such as molybdenum, manganese, nickel, chromium, vanadium, silicon, and boron. According to the different added elements and appropriate processing techniques, alloy steel can obtain special properties such as high strength, high toughness, wear resistance, corrosion resistance, low temperature resistance, high temperature resistance, and non-magnetic properties. Those have less than 5% alloy elements is are categorized as low alloy steel, these have alloy elements ranging from 5%-10% are categorized as minimum alloy steel, those have more than 10% alloy elements are categorized as high alloy steel.

Flanges made of alloy steel are widely used in water lines, oil, and gas, chemical plants, food production systems, etc. where high corrosion resistance, high temperature resistance and high pressure resistance are required.

Product Information

| Product Name | ASTM A182 F1 F5 F9 F11 F12 F22 F91 ANSI B16.5/B16.47 SW Alloy Steel Socket Weld Flange |

| Size Range | 1/2’ to 24” |

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500, |

| Thickness | Sch10S to Sch160 |

| Standards | ASME/ANSI B16.5/B16.47, JIS B2220 |

| Type | Socket Weld (SW) |

| Origin | China |

| Applications | Offshore, Oil Field, Shipbuilding, Water System, Nature Gas, Pipe Projects, Electric Power, etc. |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, Ultrasonic flaw detector, Magnetic particle detector |

| Test Certificates | Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

Chemical Composition of Alloy Flange Material

| Grade | Steel Names | C | Mn | Si | P | S | Cr | Mo |

| ASTM A182 F1 | C-0.5Mo | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| ASTM A182 F5 | 5Cr-0.5Mo | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| ASTM A182 F9 | 9Cr-1Mo | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

| ASTM A182 F11 | 1.25Cr-0.5Mo-Si(CL1/CL3) 1.25Cr-0.25Mo–Si (CL2) | 0.5-0.15 | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 1.0-1.5 | 0.44-0.65 |

| ASTM A182 F12 | 1Cr-0.5Mo | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| ASTM A182 F22 | 2.25Cr-1Mo | 0.5-0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

| ASTM A182 F91 | 0.15 max | 0.3-0.6 | 0.5-1.0 | 0.03 | 0.03 | 8-10 | 0.9-1.1 |

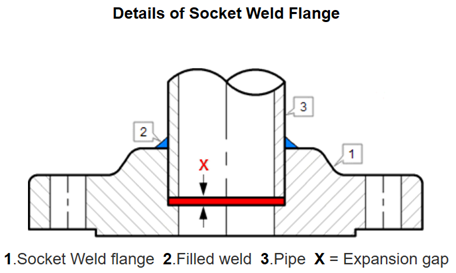

Flange Type: Socket Weld (SW)

Socket Weld flange

Socket Weld flanges were initially developed for use on small-size high pressure piping. Their static strength is equal to Slip On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges.

The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, a space must be created between flange or fitting and pipe.

ASME B31.1 1998 127.3 Preparation for Welding (E) Socket Weld Assembly says..In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16" (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.

The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap.

The disadvantage of this flange is right the gap, that must be made. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange can give corrosion problems. In some processes this flange is also not allowed. I am not an expert in this matter, but on the internet, you will find a lot of information about forms of corrosion.

Manufacturing Process