Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK A214 CS Helical Condenser Extruded Fin Tube

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Extruded Fin Tube Product Description:

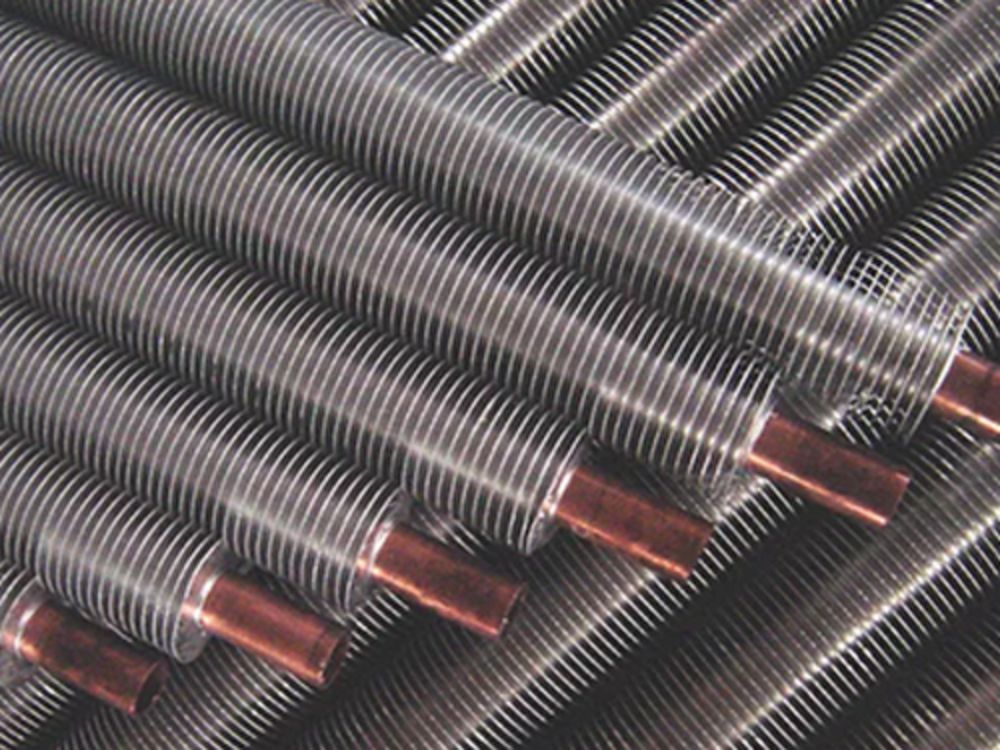

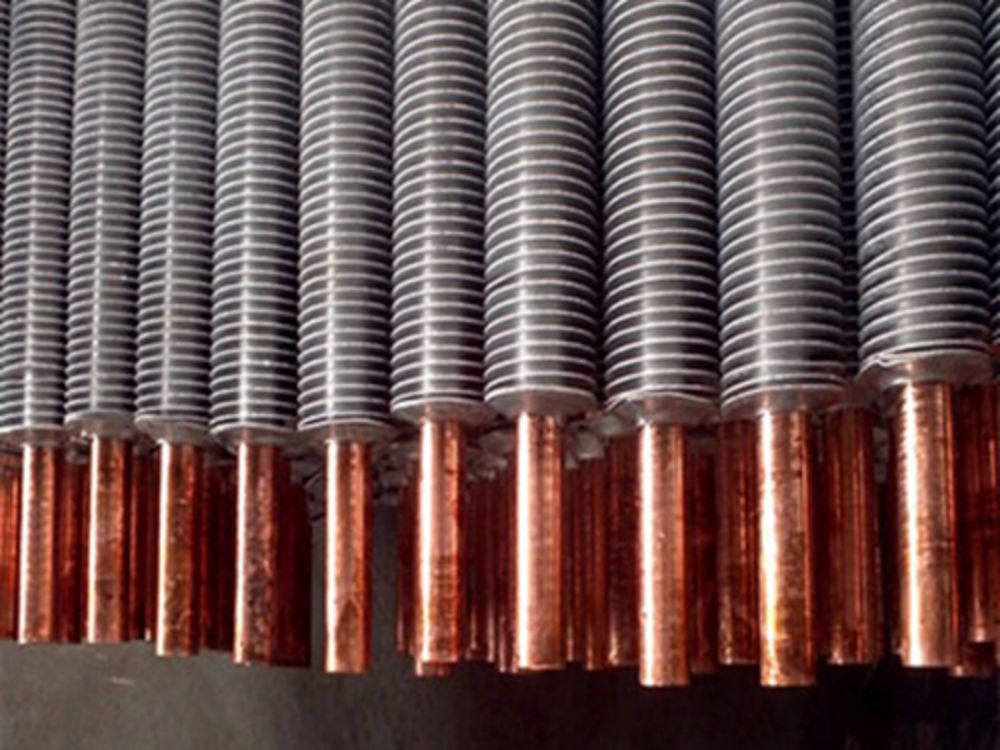

This fin type is formed from a bi-metallic tube consisting of an aluminium outer tube and an inner tube of almost any material. The fin is formed by rolling material from the outside of the exterior tube to give an integral fin with excellent heat transfer properties and longevity. Extruded fin offers excellent corrosion protection of the base tube. Maximum operating temperature for this fin type is 280°C.

Fin material: Aluminium.

Tube materials: No theoretical limits.

Extruded Finned Tube Manufacturing Process:

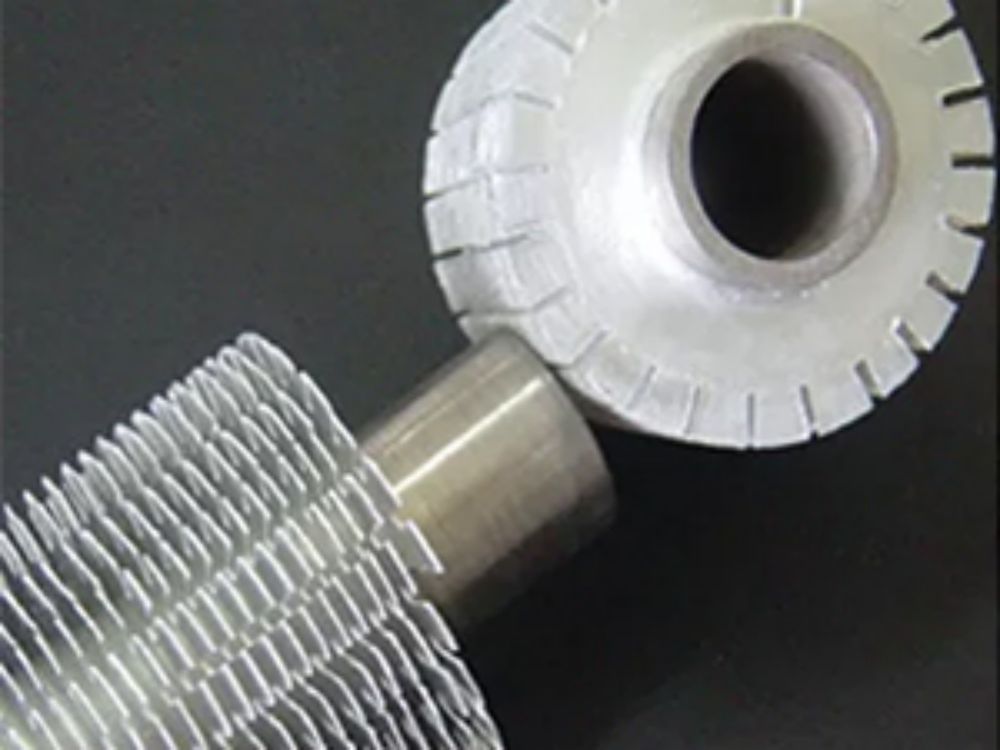

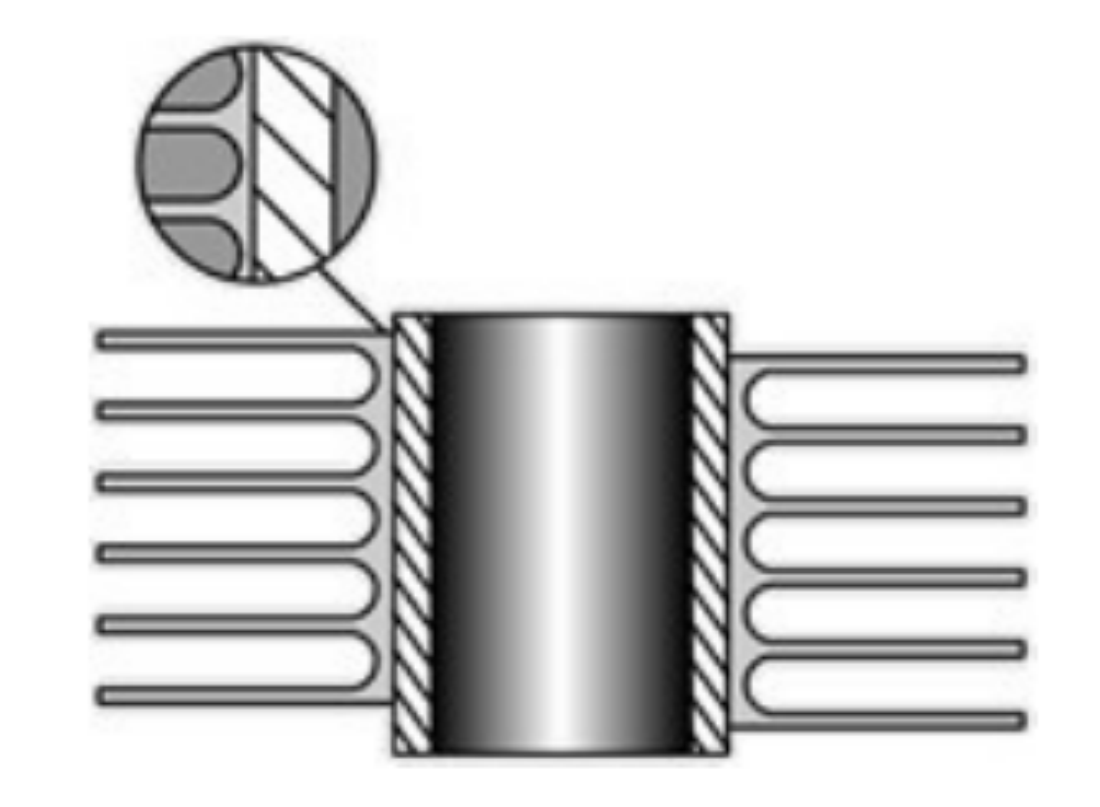

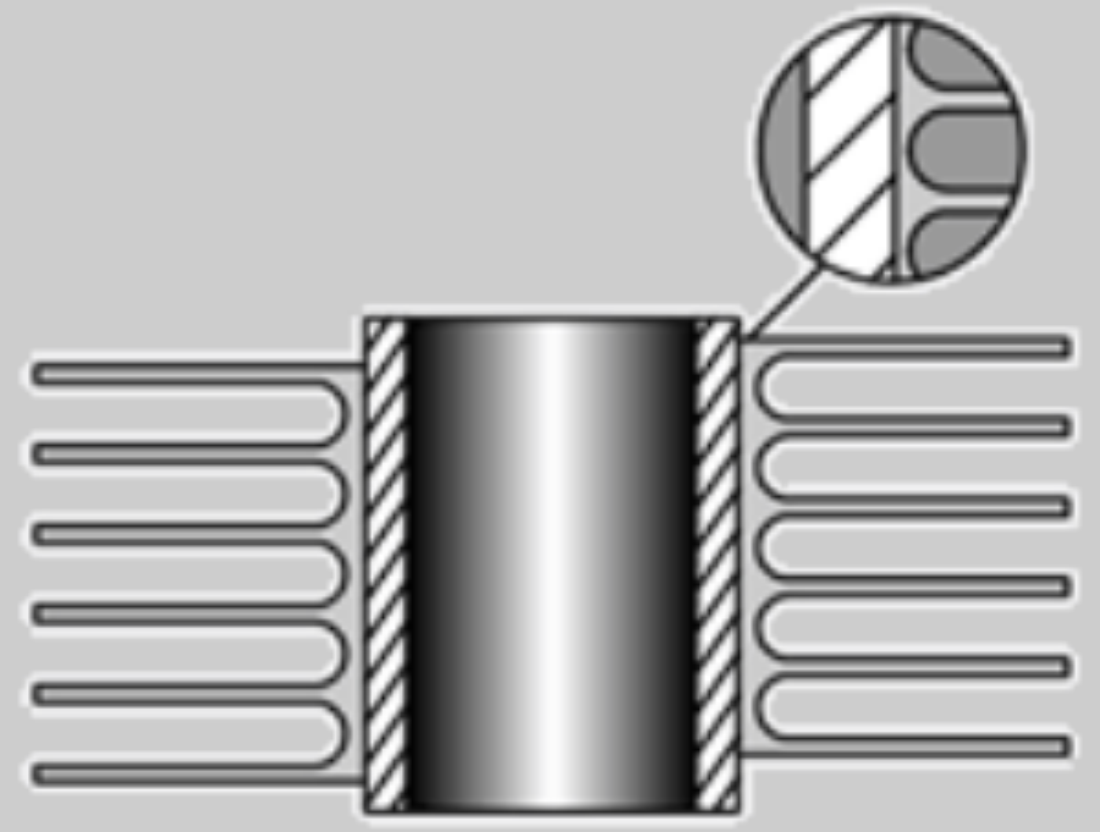

The fins are rotary cold rolled from a smooth thick walled hollow blank tube slid over the core tube. Three multi spindle disc packs extrude the hollow blank tube into helical high fins.

During this process the inner diameter of the hollow blank tube is reduced and at the same time pressed on the core tube. This results in a mechanically solid joint. Longitudinal slots are cut into the outer periphery with inclined fin tips.

Fin Material: Aluminium.

Core Tube Material: Carbon Steel/ Carbon

Alloy Steel/Stainless Steel/ Nickel Alloys/Copper/Copper Alloys/Titanium.

Extruded Fin Tubes Advantages:

Relative thin wall core tubes can be used.

Excellent heat transfer performance (100% contact between tube and fin).

Excellent atmospheric corrosion (complete coverage of the core tube).

Airtight fin to tube bond.

Robust fins resist mechanical damage.

Can be cleaned with high pressure water/steam.

Fin Contact: Interference fit with mechanically solid pressed bond.

Maximum Tube Wall Operating Temperature:

300°C.

Type of Service: Medium temperature, severe atmospheric corrosive environment.

Extruded Aluminum Tubing Properties:

The extruded fin is formed from an outer aluminum tube with a large wall thickness (muff), which is aligned over an inner base tube. The two tubes are pushed through three arbors with rotating discs that literally squeeze or extrude the aluminum fins up and out of the muff material in a spiral shape in one operation. The resultant fin typically has a base or root thickness of .035", average fin thickness .016" and a tip of .009", with an overall height of 16mm (5/8"). The root thickness serves to form an uninterrupted bond over the entire tube length.

Murphy disc technology now makes it possible to fin thinner muff thus offering significant material savings. Recommended standard muff wall is .176" as opposed to industry practice of .183"-.210" In addition, the same growth factor can be used for pitches from 8 - 11 FPI, allowing for standardization on one muff thickness and eliminating the need to stock multiple muff wall thicknesses. The same discs can be used to produce 5/8" (15,9mm) or 1/2" (12,7 mm) high fin.

Model B produces a 5/8" high fin on tube sizes from 25mm to 1.5" ( 38.1mm). The Model B Extruded Finning Machine is now capable of 7/16" high integral copper fin at 7 to 10 FPI within the tube size range of the machine (25mm and 1.5"). Each machine is configured for the specific production requirements of the end user.

Aluminum Extruded Tubing Applications:

Those are applied for Heat Exchanger Field , Oil refineries, Petrochemical industry, Ship-building, Power Plant Refrigeration.

All Kind of tube material can be applied as below

Fin spec can be changed follow with client requirement

Applied Temperature : 285 C (545 F)

This is for Air Cooled Heat Exchanger, Condenser, Air Heater in field of Oil Refinery,

Petrochemical Industry, Offshore and Power plants

Extruded Aluminum Tube Specifications:

| Product Specification | ||

| Tube OD | 10~51 (mm) | 0.4”~2” |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~1.2 (mm) | 0.012”~0.047” |

| Fin Height | 5~16 (mm) | 0.2”~0.63” |

| Fin Pitch | 100~555 (mm) | 3~14 FPI |

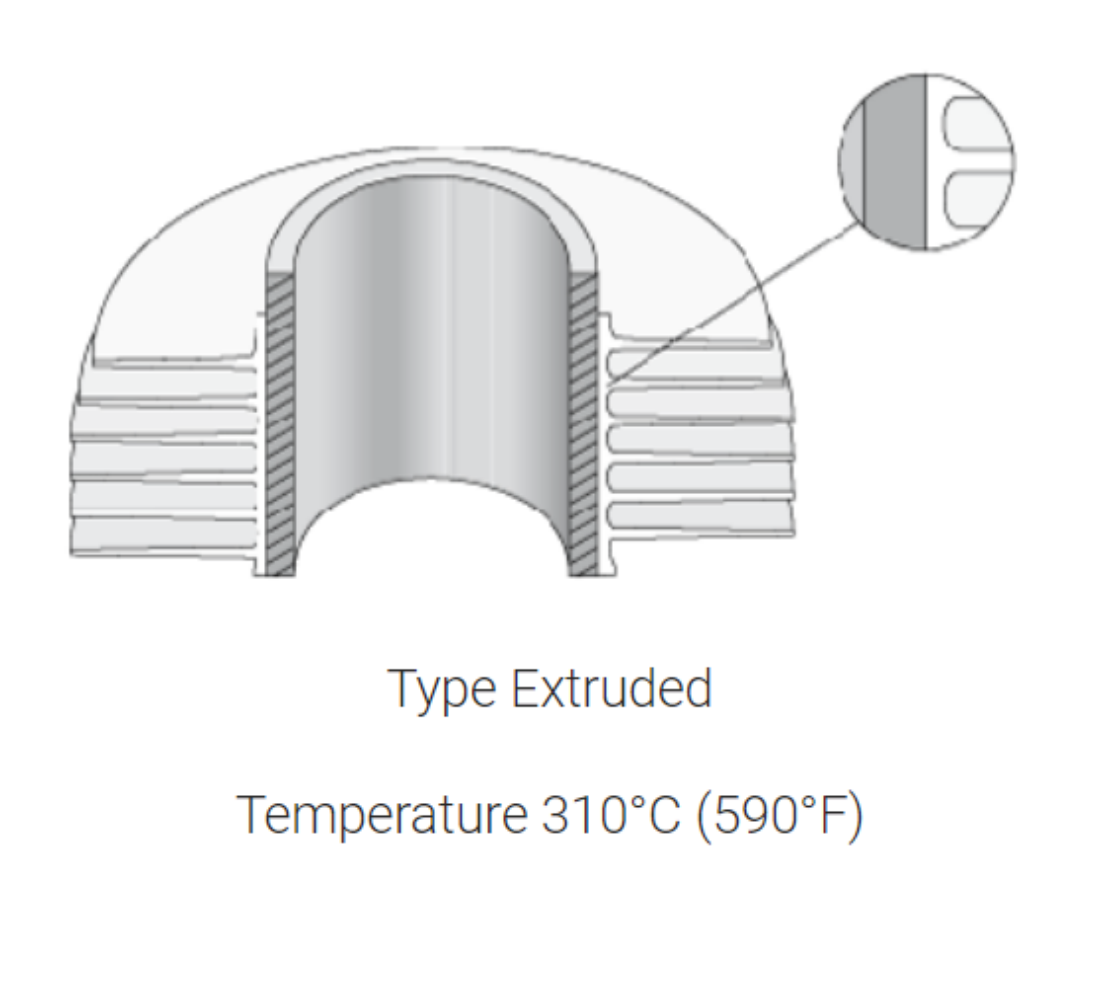

| Fin Type | Extruded | |

| Material Combinations | ||

| Fin Material | Aluminum (most common grade:Alu.1100, Alu.1060, Alu. 6063) | |

| Copper | ||

| Tube Material | C.S. (most common grade: A179, A192,SA210 GrA1/C,A106 Gr B ) | |

| S.S. (most common grade: TP304, 316, 321, 347,A789) | ||

| Copper (most common grade:UNS12200,14200, 70600, CuNi70/30, CuNi 90/10) | ||

| Titanium (most common grade: B338Gr2) | ||

| Applied Temperature | 300°C | |

| Type of Service | Medium temperature, severe atmospheric corrosive environment. | |

Product Categories : Extruded Finned Tube

Fin Type: Extruded Fin Tube

Tube Material: copper, copper nickel, stainless steel, titanium etc.

Fin Material: Copper, aluminum

Aluminum extruded finned tubes using the form of the base tube covered with aluminum tube(the base tube can be carbon steel, stainless steel, copper) through machine extrusion, forming a tube fin, the fin base and the tube outer wall is close fitting, this fin tubing control can make finned tubes with high heat transfer coefficient and heat transfer performance.

Aluminum extruded finned tubes, also called [integral finned tubes" using the form of the base tube covered with aluminum tube(the base tube can be carbon steel, stainless steel, copper) through machine extrusion, forming a tube fin, the fin base and the tube outer wall is close fitting, this fin tubing control can make finned tubes with high heat transfer coefficient and heat transfer performance. Extruded Finned Tube can be made of iron, copper or aluminum tube by compound rolling, which has the advantages of tight bonding, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong anti-corrosion performance, not easy to deformation under long-term hot and cold working conditions, long working life and so on.

Extruded finned tube manufacturing process

Pipe line--compressing or rolling--strip peeling--washing--pressure test--blast blowing--packaging.

The Extruded Fin Tube is formed by a bimetallic tube consisting of an aluminum outer tube and an inner tube of almost any material. The fin is formed by rolling the material from the outside of the outer tube to provide an integrated fin with excellent heat transfer performance and life. The extruded fins provide excellent corrosion protection for the base tube.

The production method of the composite finned tube mainly includes the extrusion method: the bimetallic composite tube is lined with a mandrel, and driven by the rotation of the roller blade, the composite tube is processed on the outer surface through the cavity formed by the rolling groove and the core head Out fins. The heat transfer tube produced by this method is an organic whole with its outer tube and fins, so there is no problem of contact heat loss, and it has good performance and high heat transfer efficiency.

FAQ

1. What Does Fin Tube Mean?

A fin tube is a tube that has small fins around the outside surface. These fins act as a filter and a mechanism to transfer heat from the material inside the tube to the outside space or vice versa. Fin tubes are used in applications that require a transfer of heat from a hot fluid to a colder fluid through the tube's wall. The rate at which such heat transfer occurs depends on three factors:

The temperature difference between the two fluids.

The heat transfer coefficient between each of the fluids and the tube wall.

The surface area to which the fluid is exposed.

2. Where is finned tube heat exchanger used?

Finned tube heat exchangers generally use air to cool or heat fluids such as air, water, oil or gas, or they can be used to capture or recover waste heat. These heat exchangers can used in a broad range of industries including oil & gas, power generation, marine and HVAC&R.

3. What is extruded fin tube?

Extruded finned tubes are bimetallic tubes whose outer aluminium surface is finned by cold plastic deformation. There are two major types of finned tubes available with us, single metal tubes (also called mono metallic fin tube) and Bimetallic tube (composite extruded fin tube) .

4. Why Aluminium is recommended as a fin material?

Good corrosion resistance, formability and high thermal conductivity make aluminium an ideal material for the construction of these heat exchangers. A typical brazed heat exchanger (radiator or condenser) comprises fins, tubes, sideplates and headerplates.

5. Where are extruded fin tubes used?

Extruded Fin Tubes are widely used in the refinery, petrochemical and chemical industry for:

Air-cooled condensers

Air-cooled coolers for products

Gas coolers

Gas heaters