Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

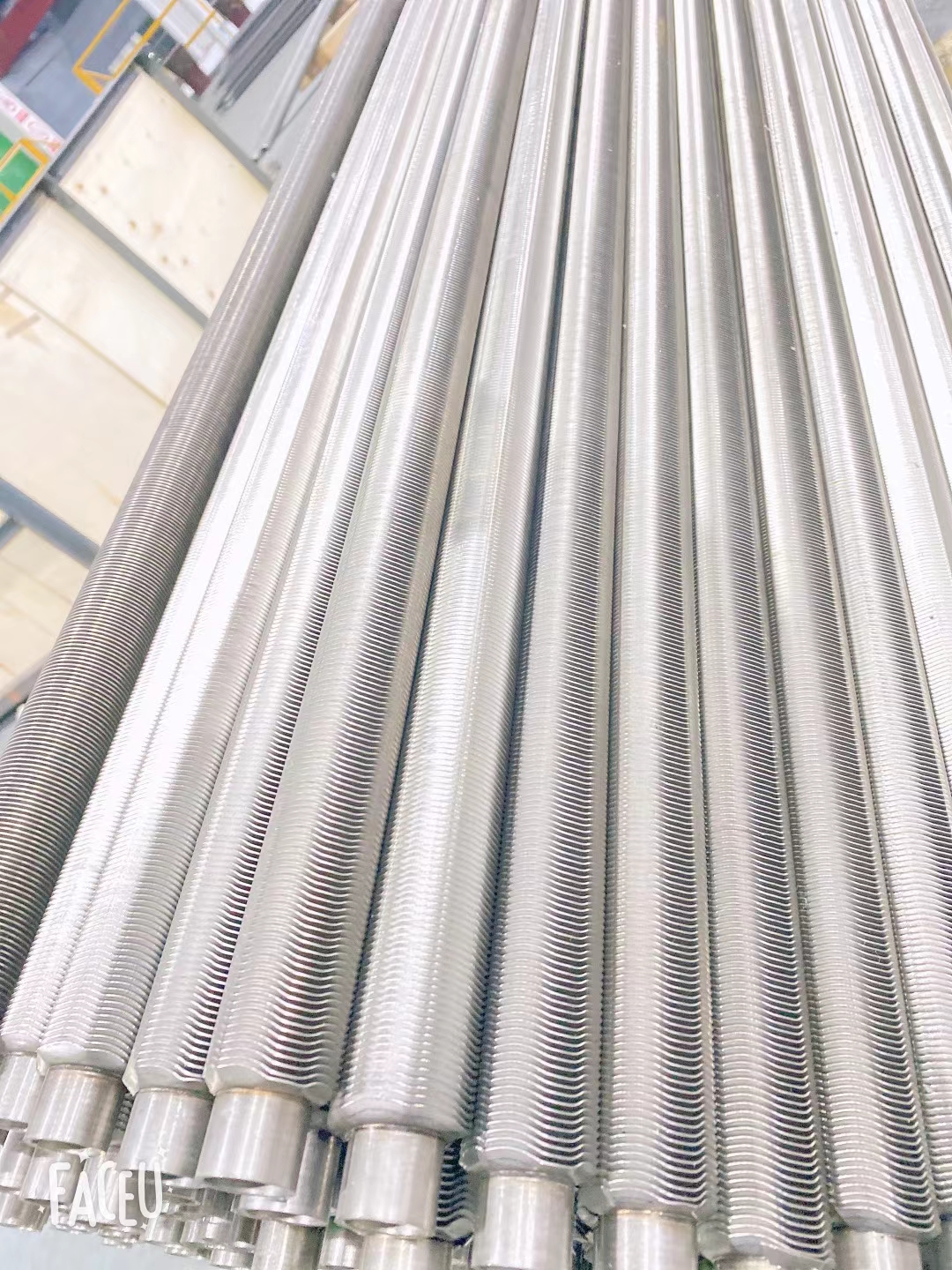

DELLOK Copper Aluminum Extruded Fin Tube For Machinery Coolers

About Us

Dellok(YONGHUI Radiating Pipe Manufacturing Co.,Ltd) was established in 2002, which is located in Nanjing, China.We joined HARBIN AIR CONDITIONING CO., LTD. in 2022 and became the most professional industry manufacturer in China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above.

Quality is the theme of eternal pursuit of winner.

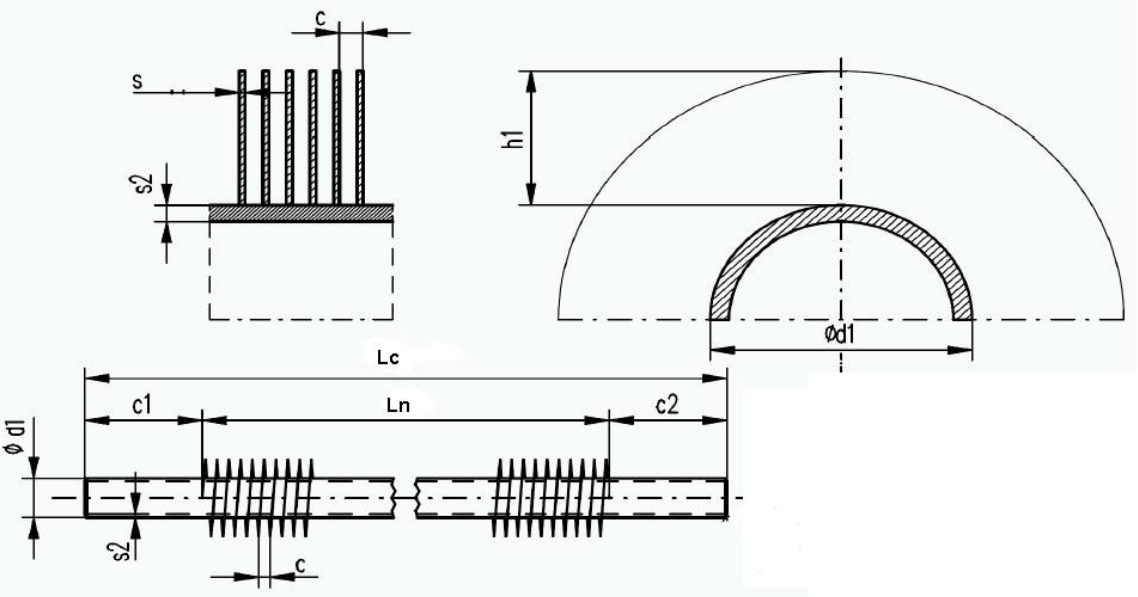

With an aim to increase the heat exchanging efficiency, It's

usually to extend the surface area (or internal surface area) by

adding fins onto a tube, which, through this manufacturing process,

would greatly improve and upgrade the heat transferring efficiency

of heating tube, it's called Finned Tube or Fin Tubes.

1. Anti-corrossion

2. Anti-wear

3. Lower contact resistance

4. Higher stability

5. Anti-fouling ability

But, as a element of Heat Exchanger, fin tubes would be working on very high temperature condition for long time. For example, the application of boilers, which is with bad ambience, high temperature, high pressure and corrossion, all require the fin tubes to be qualified with very high performance capacity as following:

Finned Tube Aluminum Fins Heat Exchanger Tube

The spiral Fin Tube economizer is a newly type heat transfer equipment, consisting of spiral fin tubes to overcome the serious abrasion and short service time.Which consisted of series of spiral finned tubes, the headers of inlet and outlet, bend, frame and other auxiliaries

Structure arrangement: in line/staggered arrangement.

Finned Tube Aluminum Fins Heat Exchanger Tube Features

1. The equipment body can be designed into many modules to ensure the long term and stable running.

2. Compact structure which can enlarge the heat exchanging area in order to add the heat transfer area and less leakage.

3. Improve the heat transfer efficiency.

4. Structure arrangement: In line or staggered arrangement.

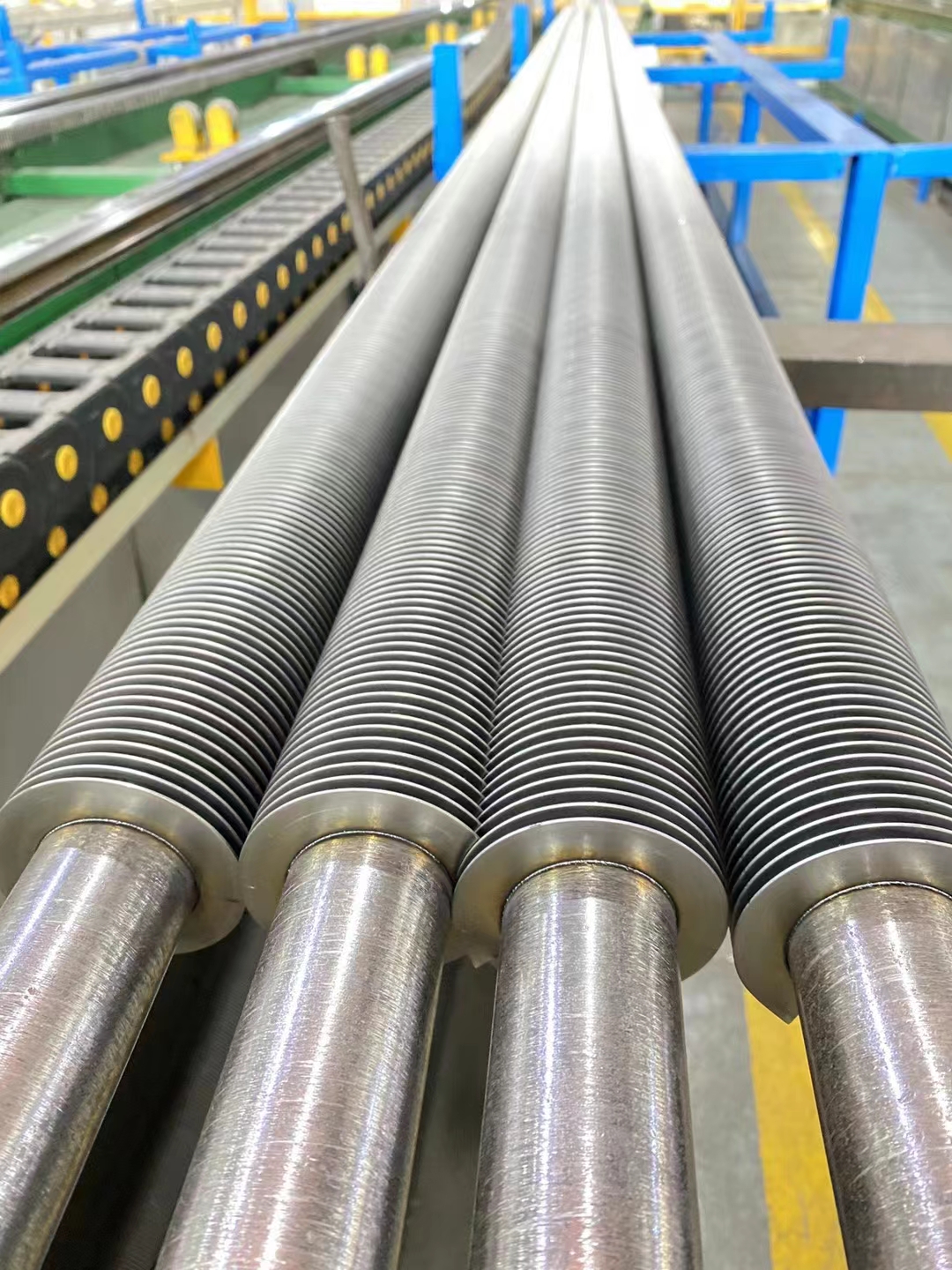

Extruded Fin Tube

Heat Exchanger Extruded Fin Tube

Finned Tube Aluminum Fins Heat Exchanger Tube Application

Aftercoolers, air coolers, air heaters, charge air chillers, condensers, convection heaters, electric heaters, evaporators, fluid coolers, gas coolers, heat pipes, hydrogen coolers, industrial tumble dryers, intercoolers, immersion heaters, oil coolers, radiators, refrigeration, solvent recovery and steam to air heat exchangers.

Product Categories :Extruded Fin Tube

Fin Type: Laser welded finned tube

Tube Material: steel, copper, titanium etc.

Fin Material: steel, aluminum, copper, titanium etc.

Product description:100% welding between fin and tube without using filler material. No impurity of the weld seam, as the laser welding is carried out under a protective atmosphere.

Laser welding finned tube is processed by laser welding machine. Laser welding is a welding method that irradiates a high-intensity laser beam onto the metal surface. Through the interaction of the laser and the metal, the metal absorbs the laser light and converts it into heat, melting the metal to form a cooling crystal. Laser welding machine is the most advanced laser welding equipment for finned tubes. Because the welding process is fully automatic and mechanical, the scientific and technological content and quality of laser welding finned tubes are superior to traditional cooling tubes.

The laser welding finned tube has a fully automatic welding process, saving manpower costs; secondly, the laser welding fin is firm, strong, and the test with high tensile strength is qualified. Laser welding is more efficient.

1. The laser welding finned tube (finned tube) fin machine has a high degree of automation, and the welding of the fin to the tube and the winding of the tube are synchronized

2. 100% welding rate, laser welding finned tube and fins are strong, the welding strength exceeds 600MPa.

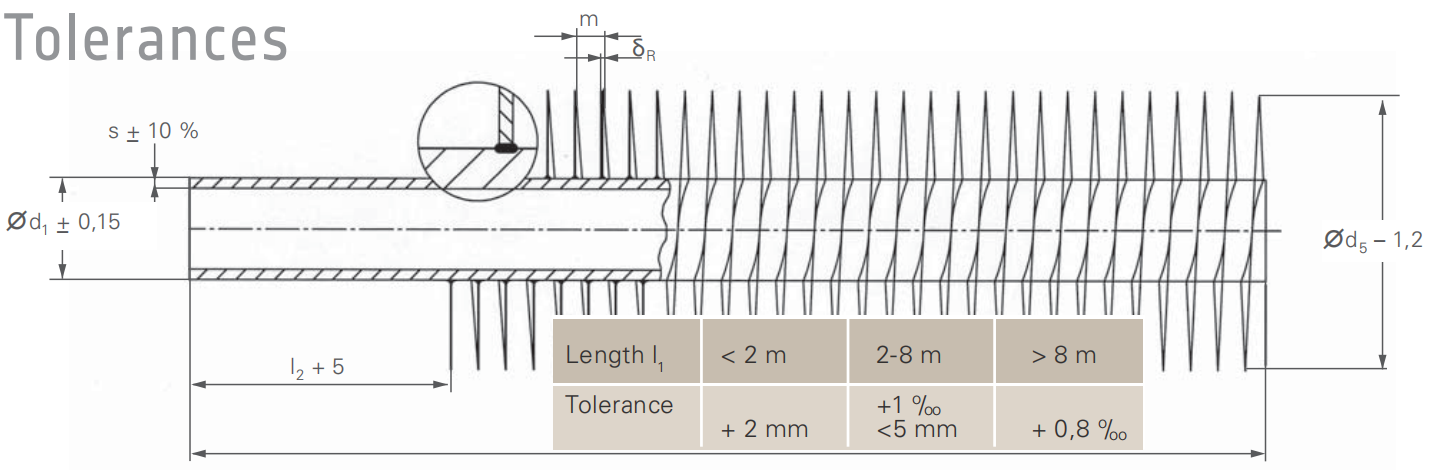

3. The precision of laser welding tube finishing machine is up to 0.05mm

4. 0 contact resistance, achieve high efficiency of heat transfer of spiral finned tube by laser welding.

5. Save production costs. The laser welding finned tube (finned tube) has a smaller fin spacing, less than 2.5mm. Compared with the high frequency welded spiral (spiral) finned tube, the heat transfer area is increased by about 50%, which makes the material cost Reduced, volume reduced heat exchanger.

6. The advantages over conventional MAG / HF welding are of decisive importance. The complete connection between the fin and the base tube brings excellent heat transfer, and the thermal performance of the fin tube is increased by 2.5 times. Continuous welding prevents the notch effect, thereby avoiding the formation of v-corrosion and cracks under the condition that the finned tube may swing. The heating of base metals during welding is low and the travel speed is up to 20m / min. Minimize the heat affected zone in the base tube. Therefore, it does not include the complete melting of the tube and the related metallurgical transformation of the parent metal.

· Tube outside diameter 8.0–50.0 mm

· Fin outside diameter 17.0 –80.0 mm

· Fin pitch 5 –13 fin/inch

· Fin height 5.0 –17 mm

· Fin thickness 0.4 – 1.0 mm

· Maximum tube lengths 12.0 m

Frequently Asked Questions (FAQ)

1. What are finned tubes used for?

Finned tubes are the main components of heat exchangers. They are a series of tubes where fins have been added on the outside to increase the contact area with the outside fluid, to exchange heat and between the fluid inside the tube and the fluid outside the tube.

2. How are finned tubes made?

The finned fin tube is simple to manufacture. The metal band is mechanically or welded around one end of the tube. The metal band is tightly wound on the outer wall of the tube by the torque of the tube. The other end is fixed to form a finned fin tube.

.

3. What are features of Laser Welded Finned Tubes?

· thin, continuous weld seam

· small heat-affected zone

· only slight discoloration weld site

· only slight microstructural change in tube and fin

· high utilization of heat for forming the seam

· increased safety because of the avoidance of crevice corrosion due to the high weld integrity between tube and fin

· no impurity of the weld seam, as the Laser-welding is carried out under a protective atmosphere

4. What is fin welding?

In the fin tube welding process rolled steel strip is continuously welded in spiral form on the outside diameter of a tube. The weld produced in this process is a true forge, blacksmith weld. This type of weld is comprised of a fusion between two portions of parent metal without the introduction of a filler material.

5. Where are Laser Welded Finned Tubes used?

The Laser Welding Finned Tubes find the preference in the following industrial sectors:

· Food processing;

· Chemical engineering;

· Energy & Power;

· Medicine and pharmacy;

· Rail power;

· Electromechanical device;

· Military industries;

· Domestic gas heaters.