Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

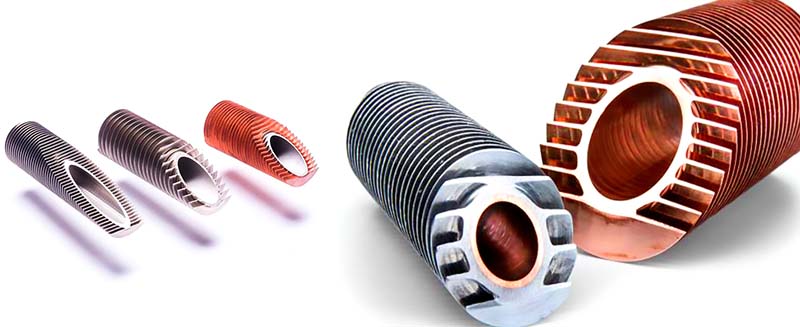

DELLOK Heat-Exchanger Aluminum Extruded Tubing for heat-exchanger

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Product Name:Heat-Exchanger Aluminum Extruded Tubing for heat-exchanger

Product model: AJX1000Z11037

Link description: The product pictures displayed on the page are for reference only. The specific product model, size, specification, material and other technical information need to be customized according to your needs.

Extruded Finned Tube Advantage:

1. Optimized inner to outer surface ratio

2. High heat exchange rate

3. Enhanced structure due to the roll forming process

4. Flexible as straight tube or bent or coiled heat exchangers

5. Low heat resistance between fins and tube

6. Strong resistance to shock and thermal expansion and contraction

7. Cost and energy saving due to long service life and high

exchange rate

In heat exchangers, fluid types, heat transfer surface areas, fluid

velocity ve pressure play an important role. In order to increase

the heat transfer surface area on tubes, fins are formed by

extrusion on tubes.

Extrusion is the process of forming fins in specified thickness,

height and pitch by extruding tube outer surface with special

machines. By this means, the heat transfer surface of the tube can

be increased. The problems caused by increasing heat transfer area

more than necessary and by extension the height of the fins formed,

are identified by studies made and by experience. Therefore fins

are designed in most suitable way to the process.

Product selection is made by considering client requirements and

places of product utilization with the calculation of efficiency

and optimal product costs. For the product selection, alternative

solutions are presented by taking environmental conditions and

safety rules into account.

Integral extruded serpentines are generally used in cascade type

condensing boilers and boilers. Serpentines that are aluminium

extruded on tubes are used in hygienic hot air generators. They can

also be used as Heat Exchanger in air cooled condenser, oil and steam applications.

The finned tube provide by us is Extruded Type, which is different from the ones through HF Welding and Wrapping method. The fins are obtained by roll forming the outer surface of a soft seamless plain tube. The technology simply squeezes the wall thickness transforming into straight fins on the tube. So the fin and the tube are integrated and inseparable, which avoids the heat resistance between fin and tube, and optimizes heat exchange efficiency. Based on this structure, the Extruded type can survive more severe working conditions than other finned tubes. Also it, on the other hand, shows several unique features such as enhanced physical structure, resistance to vibration, anti-corrosion ability, and long service life, etc.

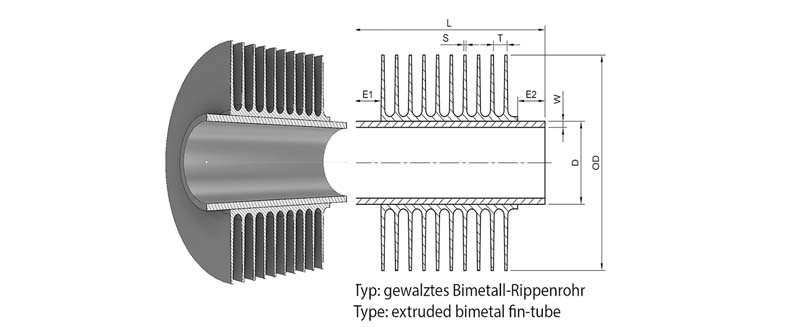

Under this technology, there are two major types of finned tubes available with us, Single metal tubes and Bimetallic tubes. The former uses Copper, Aluminum, and Copper Nickel alone. The later has a core tube on the inside made of harder material. In this case, the outer tube is rolled onto the core tube in order to provide for a tight bond and good thermal contact between the two tubes.

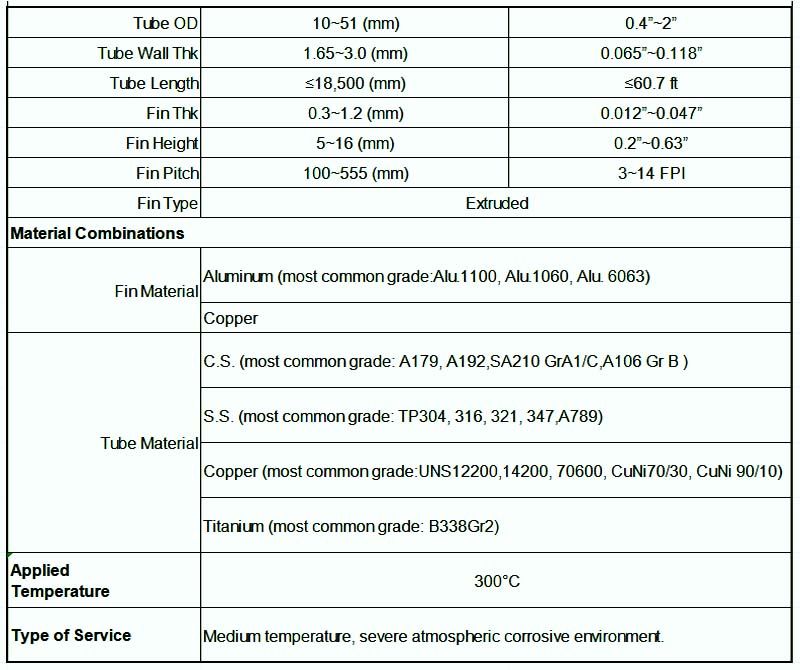

Customized finned tube is available. The specification table is followed below. If required, the fin tube can be made into various forms after soft annealing process. They can be used for cooling and heating in a large scale of conditions. For example, coils in water heater, oil cooler in large machines, heat transfer part in boiler and heat recovering system, air-conditioning and refrigeration industry as condenser part or evaporator part, etc.

The material for our fin tube covers Copper(C10200, C12000, C12200), Copper Nickel(C70600), Aluminum(1060), Aluminum alloy, Aluminum-Steel(bimetallic), Aluminum-Stainless Steel(bimetallic), Aluminum-Copper(bimetallic), Aluminum-Copper Nickel(bimetallic), Copper-Copper Nickel(bimetallic).

Advantage:

1. Optimized inner to outer surface ratio

2. High heat exchange rate

3. Enhanced structure due to the roll forming process

4. Flexible as straight tube or bent or coiled heat exchangers

5. Low heat resistance between fins and tube

6. Strong resistance to shock and thermal expansion and contraction

7. Cost and energy saving due to long service life and high exchange rate

Extruded Finned Tube Specifications:

Application Scenarios :

The fin tubes are mainly used in heating(gas-fired boilers, condensing boilers, flue gas condensers), in mechanical and automotive engineering(oil coolers, mine coolers, air coolers for diesel engines), in chemical engineering(gas coolers and heater, process cooler), in power plants(air cooler, cooling tower), and in nuclear engineering(uranium enrichment plants).

Product Description:

The fin tubes available with us covers Integrated Finned Tube of

Copper (C10200, C12000, C12200),Cupronickel (C70600), Aluminum

(1060) and Aluminum Alloy (AISI6063), Bimetallic Finned Tube such

as Copper - Aluminum, Copper Alloy - Aluminum, Steel – Aluminum,

Stainless Steel – Aluminum,Laser Welded Fin Tube using Stainless

Steel and Titanium.

We have a wide and comprehensive range of products, and we can

produce all the relevant types of products in the market.

As shown in the figure below:

FAQ

1. What Does Fin Tube Mean?

A fin tube is a tube that has small fins around the outside surface. These fins act as a filter and a mechanism to transfer heat from the material inside the tube to the outside space or vice versa. Fin tubes are used in applications that require a transfer of heat from a hot fluid to a colder fluid through the tube's wall. The rate at which such heat transfer occurs depends on three factors:

The temperature difference between the two fluids.

The heat transfer coefficient between each of the fluids and the tube wall.

The surface area to which the fluid is exposed.

2. Where is finned tube heat exchanger used?

Finned tube heat exchangers generally use air to cool or heat fluids such as air, water, oil or gas, or they can be used to capture or recover waste heat. These heat exchangers can used in a broad range of industries including oil & gas, power generation, marine and HVAC&R.

3. What is extruded fin tube?

Extruded finned tubes are bimetallic tubes whose outer aluminium surface is finned by cold plastic deformation. There are two major types of finned tubes available with us, single metal tubes (also called mono metallic fin tube) and Bimetallic tube (composite extruded fin tube) .

4. Why Aluminium is recommended as a fin material?

Good corrosion resistance, formability and high thermal conductivity make aluminium an ideal material for the construction of these heat exchangers. A typical brazed heat exchanger (radiator or condenser) comprises fins, tubes, sideplates and headerplates.

5. Where are extruded fin tubes used?

Extruded Fin Tubes are widely used in the refinery, petrochemical and chemical industry for:

Air-cooled condensers

Air-cooled coolers for products

Gas coolers

Gas heaters