Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

Seamless Solid Plain Serrated 3.1 Cert Welded Fin Tubes

| Quick Details | |||

| Condition: | New | Brand Name: | YONGHUI |

| Place of Origin: | China | Material: | Carbon, stainless, and alloy steels. |

| Fin Height: | 32 mm max. | Fin Thickness: | 0.8mm min |

| Fin Pitch: | min. 4 mm for solid fins & 3.3mm for serrated fins. | Tube Length: | 18 meters max. |

| Tube OD: | 19mm min. | Production Capacity: | Daily production capacity up to 40 tons; |

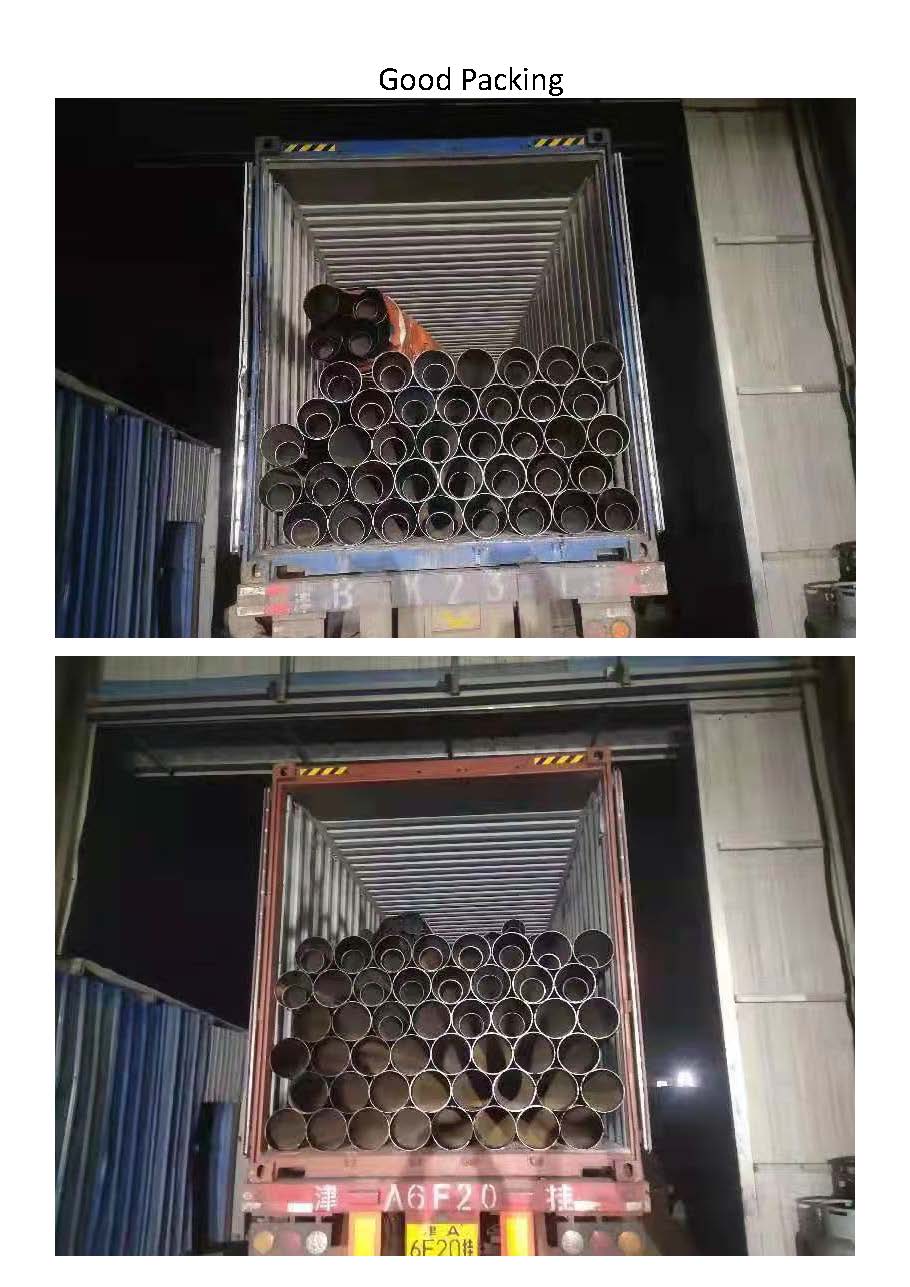

| Packing: | Steel frame with plywoods or seaworthy wooden box. | Marketing Type: | New Production 2020 |

| Warranty: | 1 Year | After Warranty Service: | Online support |

| Machinery Test Report: | Provided | Certification: | CE. ISO,EN10204. 3.1 Cert. |

| After-sales Services: | Video technical support, Online support | Showroom Location: | None |

| Local Service Location: | None | ||

Application: Seamless Carbon Steel Boiler Tubes For High-Pressure Service.

Description:

General Manufacturing Process: The fin strip is welded continuously and spirally wound onto a polished bare tube. And the tube and fins are bonded together by using high frequency resistance welding technique.

We produce both solid plain and serrated helical welded steel finned tube. And also, all spiral welding tubes could be bent in the middle or at the end of fin tubes, we call it Hairpin tubes.

Additional Services for Solid helical welded fin tubes:

Applications:

The High Frequency Resistance Welded Helical Fin Tubes are widely applied in fired heaters, heat exchanger, boilers, economizers, pre-heaters, coolers, heat pipes, heaters etc….

Specifications:

A wide range of fin and tube materials could be combinations are available.

| Items | General Materials | Popular ASTM Materials |

| Core Tube Material | Carbon Steel , Alloy Steel, Heat Resistant Steel, Stainless Steel etc. | 10#,20#,15CrMo,Cr5Mo,Cr9Mo,1Cr18Ni9Ti,0Cr18Ni9, 00Cr17Ni14Mo2,SA106B,SA106C, SA192, SA179, SA178,SA214, SA210-A1, SA210-C,TP304/304L/304H, TP409/410,TP316/316L,TP321/321L,TP347H,T11,T22,T91,etc.

|

| Fins Material | Carbon Steel , Alloy Steel, Heat Resistant Steel, Stainless Steel etc. | Q235-BF,08F,08AL, 1Cr18Ni9Ti, 0Cr13, 1Cr13, 0Cr18Ni9, 09CrCuSb, CS,A1008-B,SPHC, SPCC, TP304/304L,TP316/316L,TP321/321L,etc. |

Dimensions Data Sheet We Can Supply.

| Solid Helical Steel Fin Tubes Fabrication Range | Solid fins(mm) | Serrated fins | ||

| Min | Max | Min | Max | |

| Tube OD(mm) | 19 | 219 | 19 | 219 |

| Fin Height(mm) | 8 | 26 | 8 | 32 |

| Fin Thickness(mm) | 0.8 | 2.8 | 1 | 1.6 |

| Fins Density(mm) | 4(250FPM) | 20 | 3.3(303FPM) | 20 |

| Tube Length(mm) | N/A | 18000 | N/A | 18000 |

Additional supply range : (1) Tube swaging process for joint of 2 tubes. (2) Spacer rings (material: steel) are available. (3) One side is solid plain fins and the other is serrated fins, 2 fin types on same tube. | ||||

Our Service:

1. Inquiry-Professional quotation, or send inquiry item more details

2. Confirm the price, lead time, payment term etc

3. Proforma Invoice send or online

4. Make the samples according to your request, send you photos or samples, arrange the production

5. Send the production line photos Confirm the estimated delivery time again.

6. End Production-Mass production products photos and samples will send to you for approval.

7. Inform the tracking number and check the status for clients

8. Order can be say "finish" when you receive the goods and satisfy with them

9. Feedback to our about Quality, Service, Market Feedback & Suggestion. And we can do better