Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

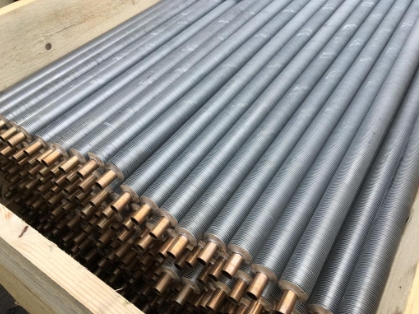

DELLOK Extruded Fin Tube High-Grade Heat Transfer for Industrial Applications

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

♦ Product Name: Extruded Fin Tube

♦ Temperature: Low Temperature/High Temperature

♦ Fin Material: Aluminum, Copper and Steel

♦ Tube Length: 1000mm

♦ Manufactured using Embedded Fin Tube Machine

♦ Available in Carbon Steel Fin Tube

♦ Also available in Aluminum and Copper Fin Tube