Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

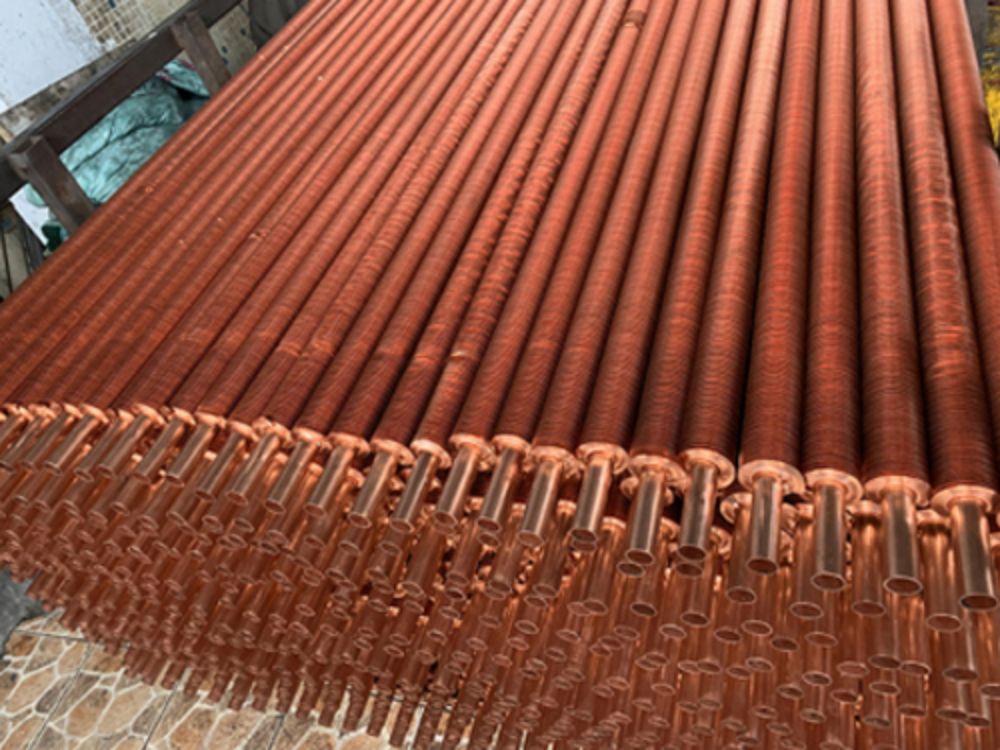

Customized Extruded Fin Tube with Copper and Steel Material Performance

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

L/LL/KL Finned Tube Product Description

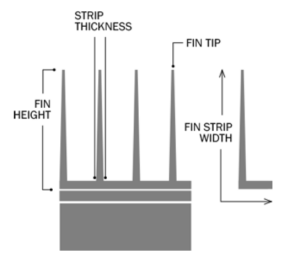

- L Finned Tube(Wrap-On Fin)

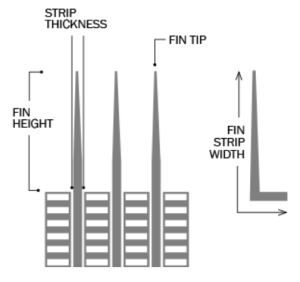

The Wrap-On (W/O) Fin or “L” footed fin is characterized as an L fin and is widely used throughout the world. This fin is considered an interference fit type fin and is limited to light duty. Typically this fin is produced out of aluminum or copper fin strip. This fin type is not suitable for carbon steel or stainless steel fin materials as the material is too hard for the formation of the characteristic L foot. The foot of the fin is formed by pulling the strip through a two stage preformer set. The first stage rolls the fin to a 45-degree foot and the second stage rolls it to a true 90-degree foot. The tooling controls the fin height as specified. As a result of this, each combination of FPI (pitch) and fin strip thickness requires a specific strip width.

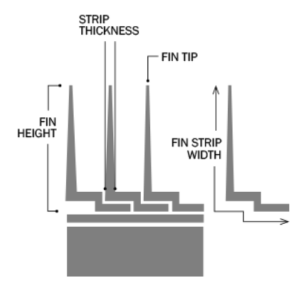

- LL Finned Tube(Overlapped Footed Fin)

The Overlapped Footed Fin (OLFF) is characterized as a double LL fin and is widely used throughout the world as an alternative to the extruded fin. This fin is considered an interference fit type of fin and is used in corrosive applications where protection of the base tube is required. The double LL coverage of the base tube represents a double strip thickness coverage of the base tube. Typically, this fin is produced out of aluminum or copper fin strip. This fin type is not suitable for carbon steel or stainless steel fin materials as the material is too hard for the formation of the characteristic LL foot. The foot of the fin is formed by pulling the strip through a two stage preform roller set. By preforming the foot of the fin into a “joggle” or a one thickness offset, it is possible to take advantage of the ability to place the heel of one fin on the toe of the adjacent fin. The preformers preform the foot to allow the fins to fit together on the surface of the tube, for continuous contact with the base tube and forms a seal to protect the base tube from atmospheric corrosion.

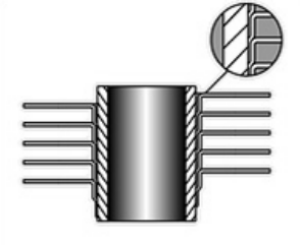

- KL Finned Tube(Knurled Aluminum Tubing)

The Knurled Footed Fin is characterized as adding increased tube and fin surface area due to the knurled surface on the fin foot and tube. The fin is consider an interference fit type fin and because of the knurls some heat transfer specialist give the fin added performance ratings due to a mechanical type bond of the fin material to the tube wall surface. Typically, this fin is produced out of aluminum or copper fin strip. This fin type is not suitable for carbon steel or stainless steel fin materials as the material is too hard for the formation of the characteristic L or LL foot. Knurling depth in the tube wall is affected by the hardness of the tube material chosen. The fin, whether W/O or OLFF, is formed using standard fin height hardware.

L/LL/KL Finned Tube(Knurled Aluminum Tube) Manufacturing Process

Applied Fin Tube is made with strip wrapped under tension around the base of the tube. Fins are welded to the base tube at the strip ends.

L/LL/KL Finned Tube(Aluminum Finned Tubes) Advantages

Core tube extensively protected against corrosion by the fin foot, finning of very thin-walled tubes possible.

L/LL/KL Finned Tube Properties

Atmospheric Corrosion Resistance: OK

Mechanical Resistance: Poor

Fin Contact: Interference Fit

Fin To Tube Bond :Moderate

Heat Transfer Efficiency :Moderate

L/LL/KL Finned Tube Applications

-the petroleum, chemical and petrochemical process industries

-natural gas treatment

-the steel industry: blast furnace and converter systems

-power generation: steam turbine exhaust condensing

-contact condensing with cooling of circulating condensate

-fossil and nuclear power plants

-air conditioning (Freon, ammonia, propane)

-incineration of household refuse

-compressor coolers, etc.

Product Categories : L/LL/KL Finned Tube

Fin Type: L/LL/KL Finned Tube

Tube Material: Carbon steel, stainless steel, copper, aluminum

Fin Material: Copper, aluminum

Fin Tube Length: No Limit

Working temperature: 230℃.

Features: Adopting the winding process, the production efficiency is high, the lamella distance is uniform, the heat transfer is good, the finization ratio is high, the base tube can be protected from air erosion.

The difference in temperature between the two fluids.

The coefficient of heat transfer between each fluid and the wall.

Surface area of fluid exposure.

L type finned tube:

Adopting the winding process, the production efficiency is high, uniform lamella distance , good heat transfer, high finization ratio, the base tube can be protected from air erosion. The aluminum fin or copper fin is folded into an L shape and continuously spirally wound on the outer surface of the base tube under the action of tension.

Maximum working temperature-150°C (302°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper.

LL type finned tube:

Under the L-shaped foundation, the fin root completely covers the outer surface of the base tube; to some extent, this fin type guarantees better corrosion resistance. Maximum working temperature-180°C (356°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper.

KL type finned tube:

Before the fins are continuously wound on the surface of the steel pipe, the outer surface of the base pipe needs to undergo a knurling process; after the fins are wound, the root of the fin attached to the steel pipe will also be knurled to strengthen the steel pipe and Combination of fins. For this reason, this fin type ensures better heat transfer characteristics under the fins of L and LL. Maximum working temperature-260°C (500°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper.

Mainly used in air coolers in petrochemical, electric power, paper making, tobacco, building heating and other industries, air heaters and air heaters in spray drying systems such as vegetable protein and starch in the food industry. Blast furnace and converter systems, power generation: condensate exhaust gas discharged from steam turbines, condensate contact cycle cooling condensation, fossil and nuclear power plants, air conditioners (Freon, ammonia, propane), waste incineration equipment, compressor coolers, etc.

We customized finned tube according to customer indivisual requirement, for more details about L/LL/KL finned tube please inquire us!

FAQ

Q: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q: What is the warranty for your products?

A :We provide one year warranty for the products.

Q: What payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q: What are the modes of transportation of machines?

A: Air freight, sea freight express delivery, etc. We will choose the most suitable transportation method according to your requirements.