Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

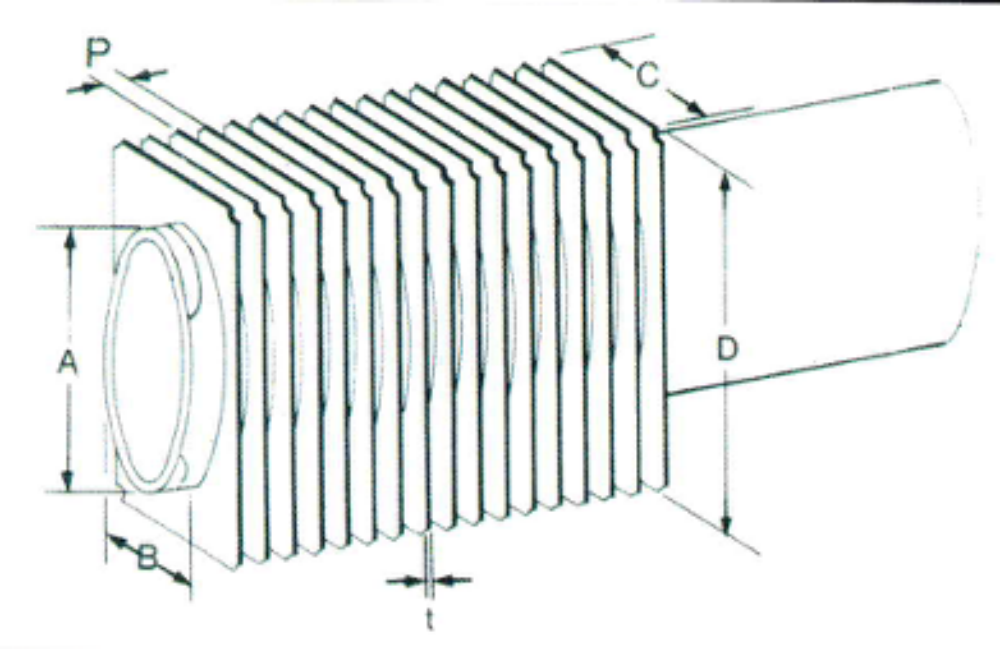

DELLOK Carbon Steel Elliptical Finned Tube For Air Cooler

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Elliptical Finned Tube Product Description:

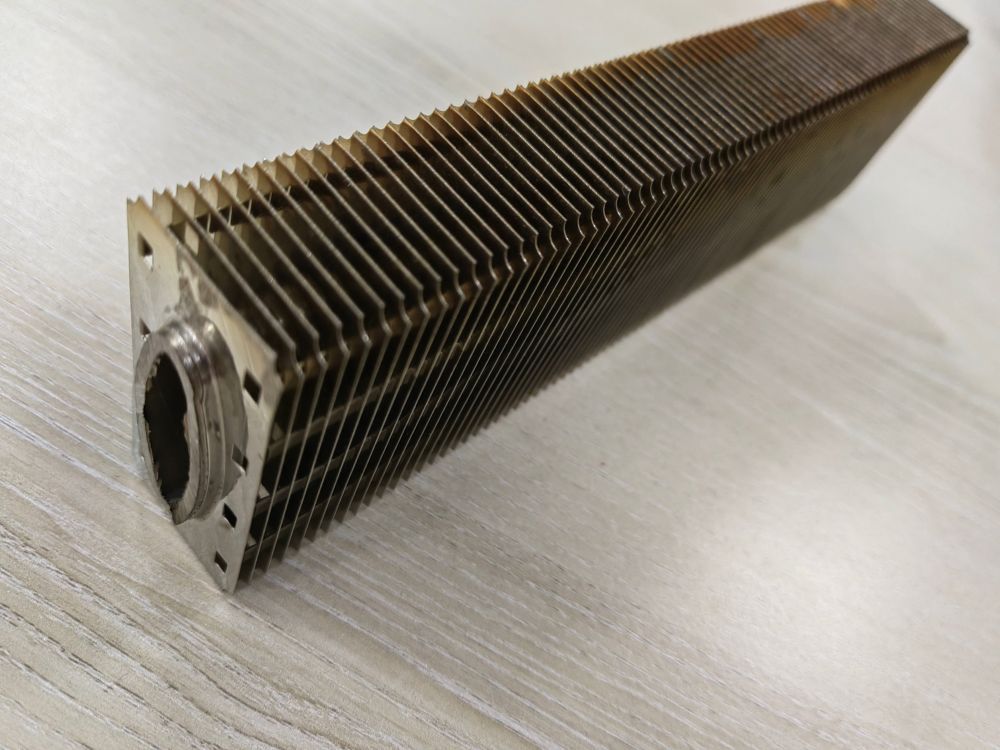

This Fin Tube design utilizes an elliptical shaped tube with an efficient air foil shape to minimize air side flow resistance. These fins have improved performance characteristics compared to round tube types.

The corrosion resistance of these fins will be very high after being hot dip galvanized. These fin tubes are very compact compared to other types of fin tubes and their heat transfer efficiency is significant.

Those are applied for Heat Exchanger Field, Oil refineries, Petrochemical industry, Ship-building, Power Plant,

Refrigerator, Steam Engine and Evaporator.

Elliptical Finned Tube(Oval Tube Aluminum) Manufacturing Process:

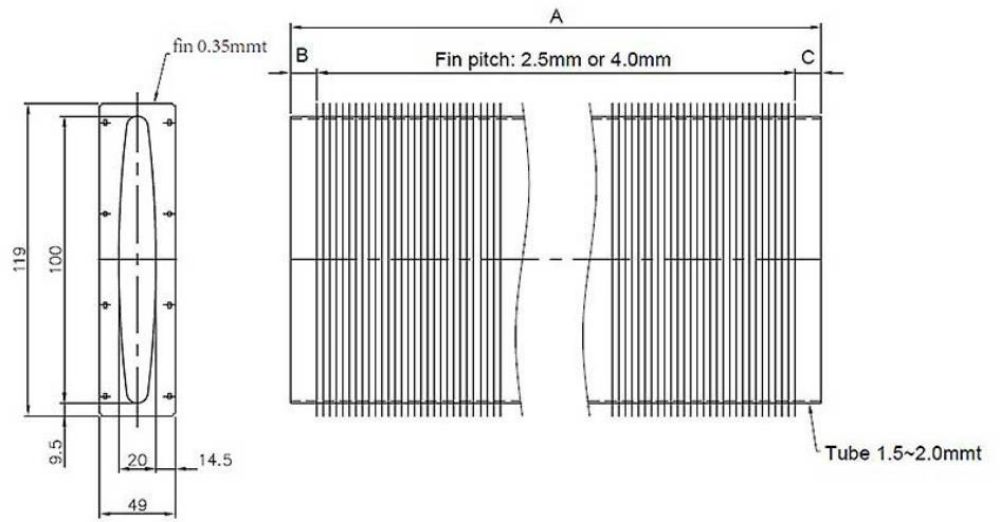

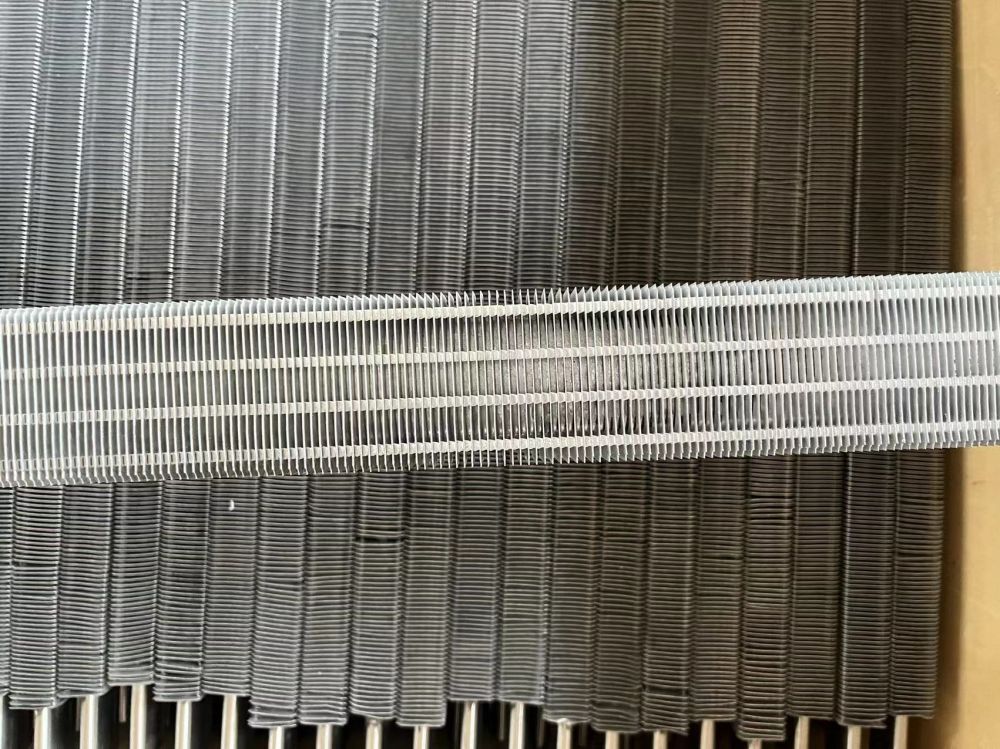

An oval seamless tube is used as the base tube, and the finned tube is spirally wound with aluminum fin tape or copper fin tape under tension and tightly wound on the outer surface of the base tube.

Elliptical Finned Tube(Oval Steel Tubing) Advantages:

The reflux zone and windward area is much smaller, reduce the hydromechanics on the air side, then reduce the energy consumption.

Inside the Heat Exchanger equipment, oval tube bundle is more compact than circular tube bundle, so the heat exchanger has smaller volume and is with lower cost.

The fins are not sensitive to typical mechanical loads, for example hailstorm or walk on the bundles.

The rectangular fins are with high strength, protecting the base tube from fracture in winter, prolonging the tube life-span.

Elliptical Finned Tube(Stainless Steel Oval Tube) Applications:

Those are applied for Heat Exchanger Field, Oil refineries, Petrochemical industry, Ship-building, Power Plant,

Refrigerator, Steam Engine and Evaporator.

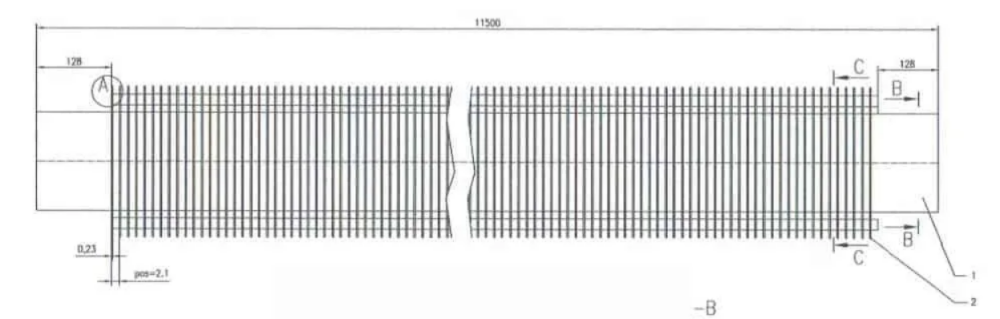

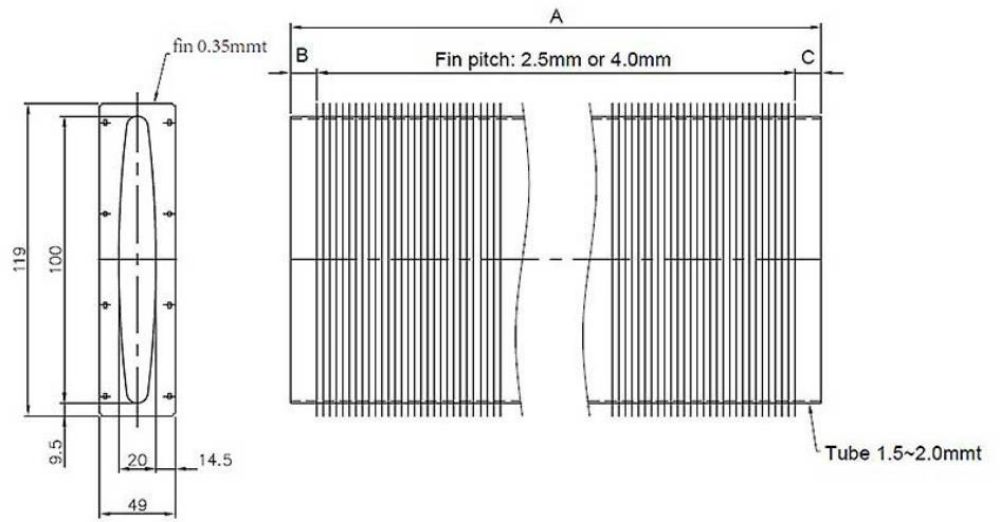

Elliptical Finned Tube Specifications:

Product Categories : Elliptical Finned Tube

Elliptical Finned Tube Material Details:

Tube material:

1. Carbon steel: A179, A192, SA210 Gr A1/C, A106 Gr B

2. Stainless steel: TP304/304L, TP316/TP316L

3. Copper: UNS12200/UNS14200/UNS70600, CuNi70/30, CuNi 90/10

4. Titanium: B338 Gr 2

Fin material:

1. Aluminum (Alu.1100, Alu.1060)

2. Copper.

3. Steel

Fin type: Solid plain

Manufacturing Process:

An oval seamless tube is used as the base tube, and the finned tube is spirally wound with aluminum fin tape or copper fin tape under tension and tightly wound on the outer surface of the base tube.Elliptical Finned Tube is combined with two different materials.

Advantages:

The reflux zone and windward area is much smaller, reduce the hydromechanics on the air side, then reduce the energy consumption Inside the heat exchanger equipment, oval tube bundle is more compact than circular tube bundle, so the heat exchanger has smaller volume and is with lower cost.The fins are not sensitive to typical mechanical loads, for example hailstorm or walk on the bundles.The rectangular fins are with high strength, protecting the base tube from fracture in winter, prolonging the tube life-span.

FAQ

Q: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q: What is the warranty for your products?

A :We provide one year warranty for the products.

Q: What payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q: What are the modes of transportation of machines?

A: Air freight, sea freight express delivery, etc. We will choose the most suitable transportation method according to your requirements.