Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

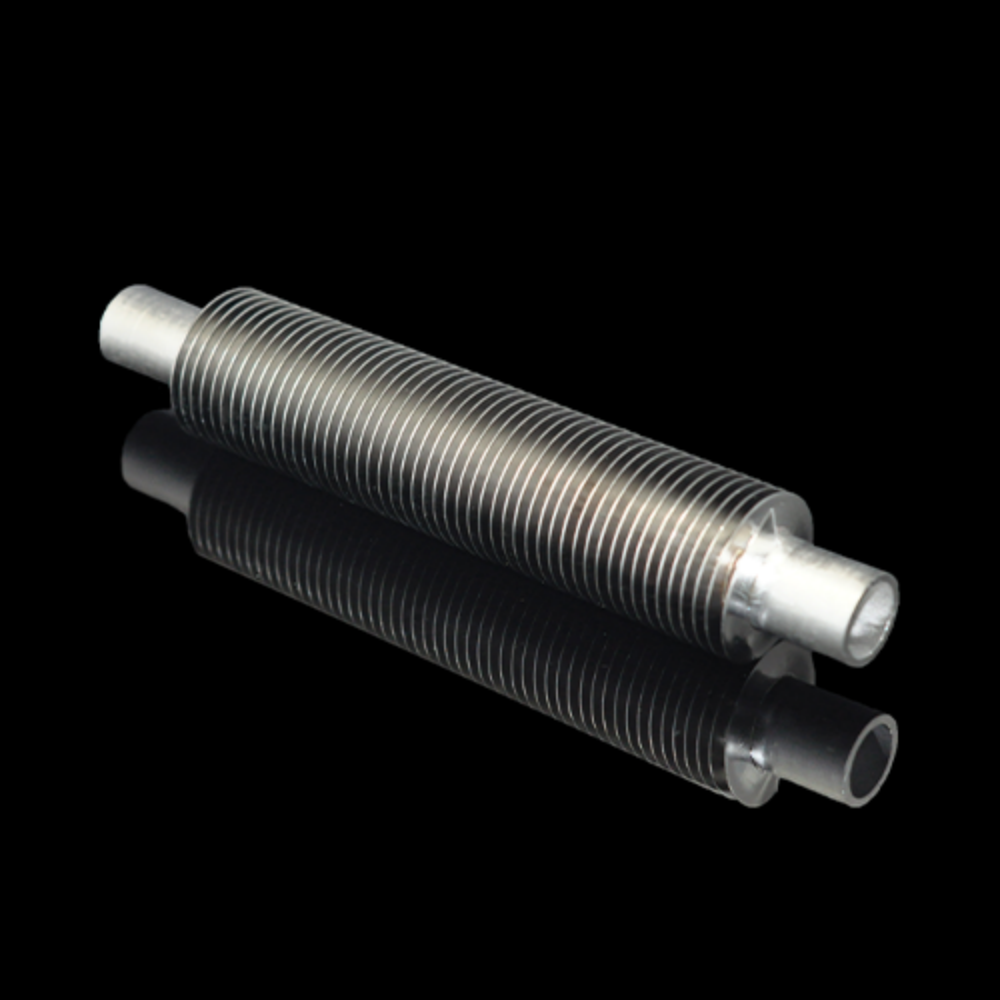

DELLOK Finned Tube For HP Evaporator

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

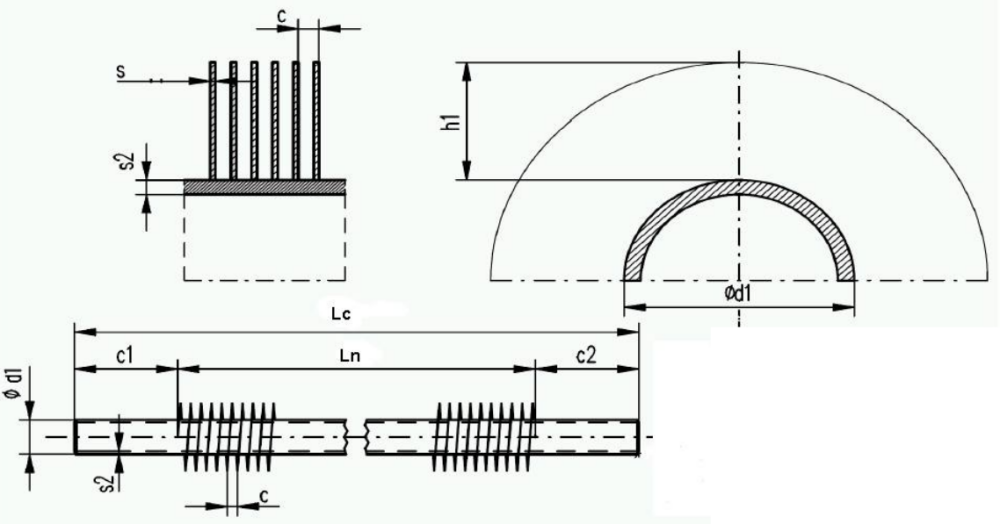

Laser Welded Finned Tube Product Description:

1.A high degree of automation, automatic fins laser welding machine can realize one-time completion of welding, synchronous winding make the fin foot and the pipe depth of weld.

2.Laser welding, high firmness, high binding force. Laser welding is metallurgical bonding, welding strength is more than 600MPa.

3.laser welding machine with high accuracy, welding a 8 meter long Fin Tube with a precision of 0.05mm.

4.The heat transfer coefficient can be improved greatly by laser welding.

5.Laser welding finned segment length is less than or equal to 2.5 mm, heat dissipation area than the high frequency welded pipe (distance is more than or equal to 4.5 mm) increased by nearly 50%, greatly reducing the material of the tube, also can decrease the change of the volume of the Heat Exchanger.

Laser Welding Fin Tube Manufacturing Process:

Laser welding is a high intensity laser beam to the metal surface, through the interaction of laser and metal, metal absorption laser into heat to make the metal melt after the formation of cooling crystallization welding.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

1.Highest Quality Product

The perfect bond between fin and tube improves efficiency in heat transfer and resistance to corrosion resulting in a clean weld fin to tube joint and fully straight fins (no corrugation).

2.New Material Combinations And Range Of Production

Our Laser Finning Process allows a wider dimensional range of tube and fin combinations. Feasible height, thickness and pitch of fins go way beyond any conventional finning process.

In addition, an increased range of material combinations of both tube and fin (steel, aluminum, copper, titanium) offers new advantages and alternatives to the industry.

3.Price Saving

Lower energy consumption, reduced cost of consumables and increased efficiency of the process allow us to offer very competitive prices.

FAQ

Q: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q: What is the warranty for your products?

A :We provide one year warranty for the products.

Q: What payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q: What are the modes of transportation of machines?

A: Air freight, sea freight express delivery, etc. We will choose the most suitable transportation method according to your requirements.