Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK Laser Weld Fin Tube For Heat Recovery Boiler

About us

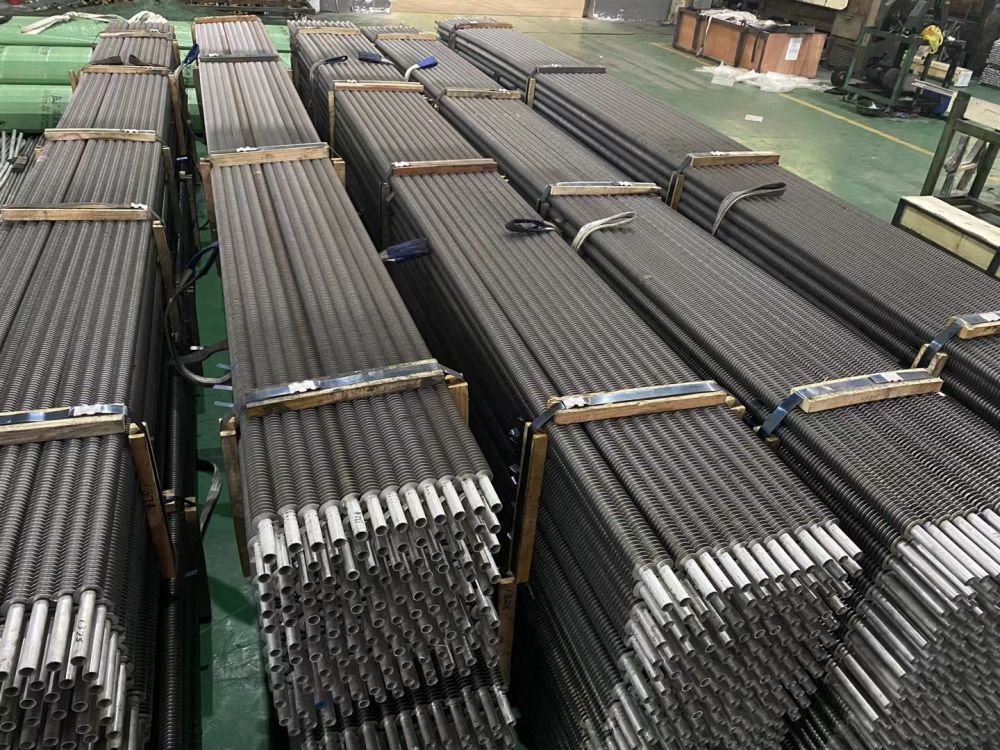

Professional heat exchanger factory with 20 years of experience, providing you with one-stop heat transfer solutions to design different heat exchangers according to your purposes (metallurgy, food, petrochemical, pharmaceutical, beverage, wastewater, refrigeration, etc...)

Dellok Young is a professional manufacturer of various heat exchangers integrating R&D, design, production and sales. The heat exchangers produced are mainly used in petrochemical, electric power, papermaking, building heating, mining and other industries, such as air heaters, food industry plant protein powder, starch and other air heater spray drying systems.

The company now has a professional technical innovation team and

professional after-sales personnel. The company's production plant

covers an area of approximately 18,000 square meters, has multiple

professional and advanced CNC and automated production equipment,

and has obtained a number of professional certificates and patents.

The company has a professional foreign trade team and has trade

cooperation with various regions. Some global partners conducted

on-site inspections of the production plants and were very

satisfied with the inspection results and established long-term

strategic cooperative relationships with our company.

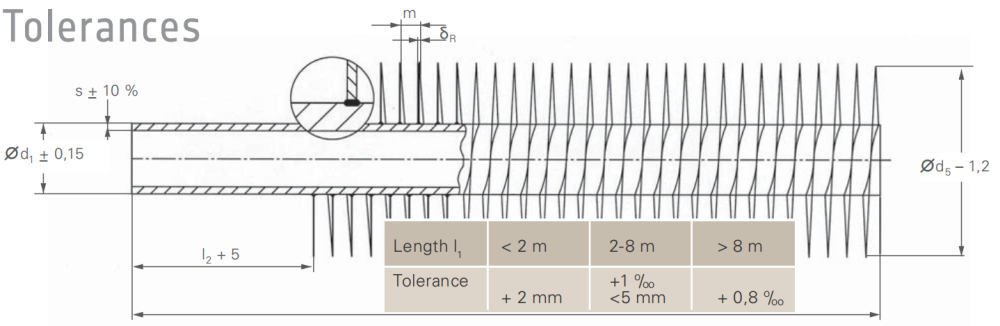

Laser Welded Finned Tube Product Description:

1.The thickness of the base tube can be 0.8-1.5 mm, and the thickness of the fins can be 0.3-1 mm in the process of operation, which greatly saves the cost of materials when operating compared to other processes.

2.The high welding head rate of laser welded finned tube can prevent the gap corrosion in the process of operation, effectively prolonging the service life and reducing the heat transfer heat resistance.

3.Laser welded finned tubes need to break through the material restrictions, in the use of its different materials for processing.

4.Laser welded finned tubes are easy to be processed twice and can be directly coiled and bent.

5.Small heat-affected zone of welding and small metallographic changes make it possible to process small diameter finned tubes.

Heat Exchanger tube and condenser tube material, should have the heat transfer performance, good corrosion resistance, scouring resistance, wear corrosion performance, also should have good strength and stiffness and plasticity, easy to process manufacturing.

Laser Welding Fin Tube Manufacturing Process:

Laser welding is a high intensity laser beam to the metal surface, through the interaction of laser and metal, metal absorption laser into heat to make the metal melt after the formation of cooling crystallization welding.

Laser Welding Fin Tube(Welded Spiral Pipe) Advantages:

1.Most Efficient:

Making thermal calculations does not have to involve an added weld wire or its splatter and so contributes and promotes to greater heat transfer efficiencies

2.Lighter:

Because the laser process does not use a foreign weld wire, there is no added weight. Only the fin or rib and the pipe

3.Full Penetration of Weld:

Due to the laser process, the entire length of the fin and pipe become “one metal” as there is no added weld wire or the required shield gas for the welding process.

4.No Gap Between Fin and Pipe Wall:

There is no void between the fin root and pipe wall which can cause crevice corrosion, an attack that usually takes place in a very tight gap between two surfaces. The gap can promote cold spots and therefor corrosion.

5.Precise, Distortion Free Welds:

Laser is precision tuned without interference of wire or shield gas. Complete melt of the fin to pipe connection along the entire length of the fin

6.Better Weld Control for Joining Dissimilar Metals:

Precision tuned per application

7.Less Splatter:

Cleaner and smoother surfaces will promote better heat transfer, less pressure drop and less opportunity for particulate buildup, no matter how small the blemishes appear to be.

8.Uniform Root Hardness:

Other welding methods can leave uneven hardness throughout the fin to pipe configuration.

Laser Welded Finned Tube(Stainless Steel Welded Pipes) Properties:

1.thin, continuous weld seam

2.small heat-affected zone

3.only slight discoloration weld site

4.only slight microstructural change in tube and fin

5.high utilization of heat for forming the seam

6.increased safety because of the avoidance of crevice corrosion due to the high weld integrity between tube and fin

7.no impurity of the weld seam, as the Laser-welding is carried out under a protective atmosphere

Laser Welded Finned Tube(Stainless Steel Welded Pipe) Applications:

1.Power Plants

2.Chemical Industry

3.Heat Recovery Plants

4.Heat Industry

Product Categories : Laser Welded Finned Tube