Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK Seamless Copper Integral Low Fin Tube

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

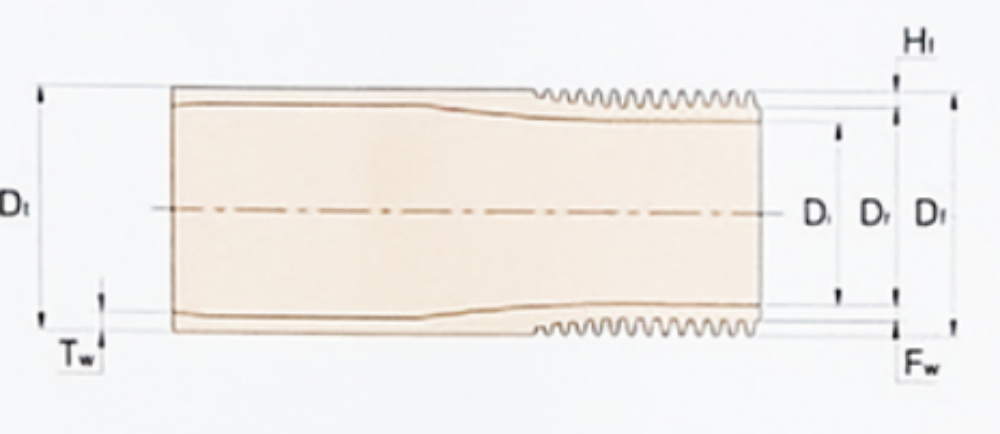

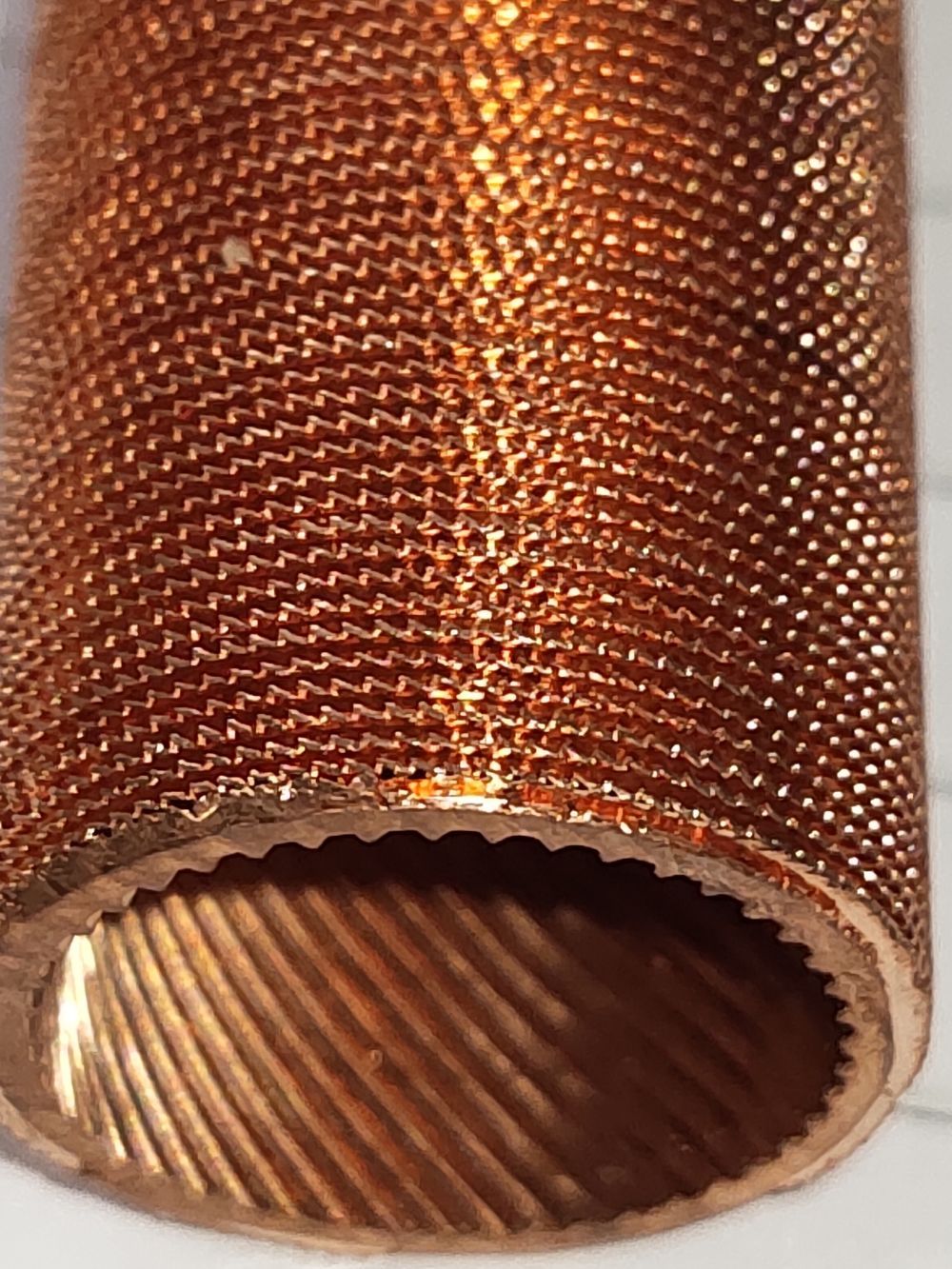

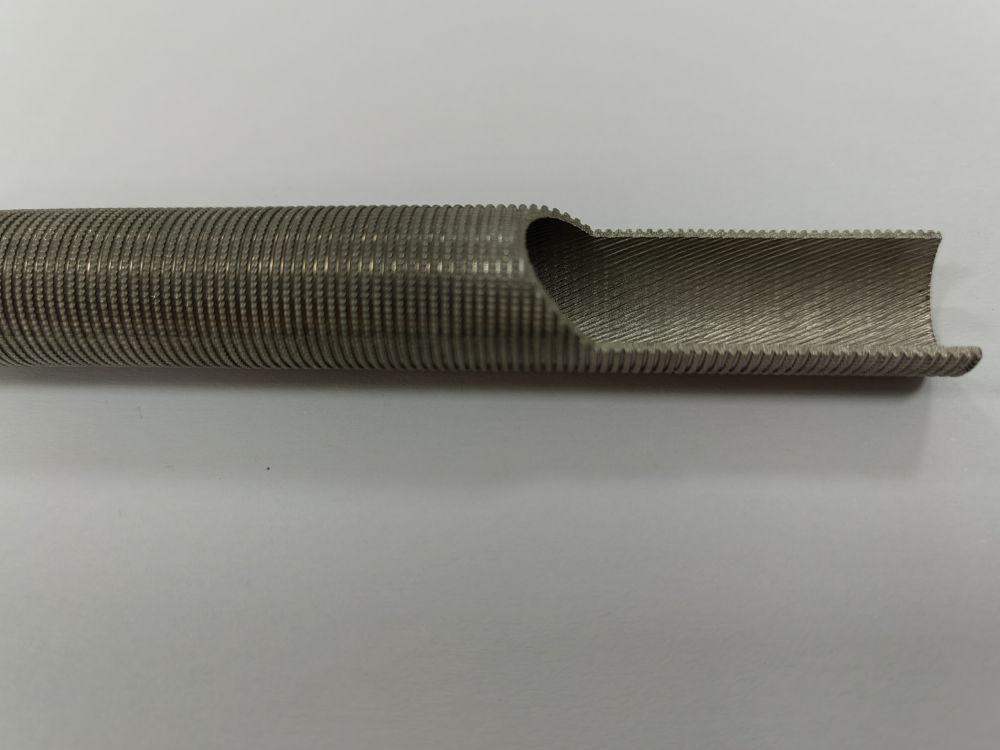

Low Fin (Integral) tubing is a type of extruded tubing that consists of short low fins.The low fin tube have the advantage of adding surface area to a smooth tube while maintaining the same outside diameter. Low Fin Enhanced tubes can be used in standard shell and tube baffles and tube sheets.This method of construction is very different from cutting grooves onto the tube as is often done by people who are on the lookout for a shortcut or who don’t know any better.The uses differ, but as far as pipes with an increased outer surface area are concerned, they are all tubes with welded peripheral fins onto steel pipes, also known as high fin tubes. Low finned tubes involve the formation of fins by direct rotational processing of steel pipes, meaning there is no worry of detachment even if later bent. Moreover, they possess excellent durability and anti-vibration properties once put into operation.A Low Fin Tube is formed by passing a tube through a set of rollers that form the fins from the parent material of the tube by making it flow in the desired way.

Manufacturing Process

Low fin (integral) tube is an extruded tube consisting of short low fins, the fins are rolled out from the outer wall of the plain tube by rollers, and the tube and fins are in the same piece of tube.

Integral Low Finned Tube Advantages

Offers 2.5-3 times the external surface area of bare tube

Enhanced heat exchanger efficiency means less tube is required to accomplish the same heat transfer as a bare tube

Low finned tube can increase the performance of an existing exchanger without the difficult and expensive task of building new shells etc

Reduced space and weight can be extremely valuable in offshore production or high elevation distillation columns. Low finned technology can transform large shell and tube exchangers into compact heat exchangers.

Low Finned Tube Properties

Low maintenance

Persistent against rust

Light weight

Integral Low Fin TubeApplications

Generator of absorb refrigerator,condenser of refrigeration system and heat transfer of other industries,screw cold water units,full liquid evaporator of centrifugal and evaporator,oil cooler.

Integral Low Fin Tube Specifications

| Product Specification | ||

| Tube OD | 12.7~31.75 (mm) | 1/4”~1 1/4”(NPS) |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.0118"~0.0197” |

| Fin Height | 0.9~1.3 (mm) | 0.0354”~0.0512” |

| Fin Pitch | 666~1111 FPM | 16~30 FPI |

| Fin Type | Integral Low | |

| Material | ||

| Tube Material | C.S., S.S., A.S., Copper, Titanium | |

| Applied | 415°C | |

Temperature | ||

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.