Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

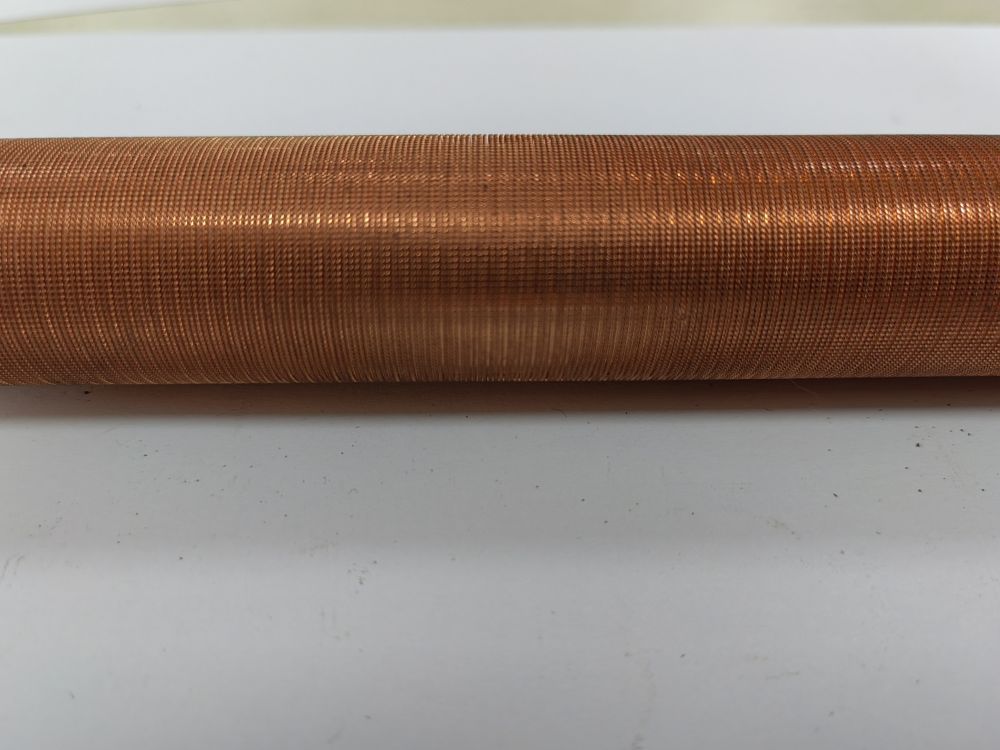

DELLOK Supply Industrial Copper Integral Low Finned Tubes

About Us

Dellok(YONGHUI Radiating Pipe Manufacturing Co.,Ltd) was established in 2002, which is located in Nanjing, China.We joined HARBIN AIR CONDITIONING CO., LTD. in 2022 and became the most professional industry manufacturer in China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above.

Product Description

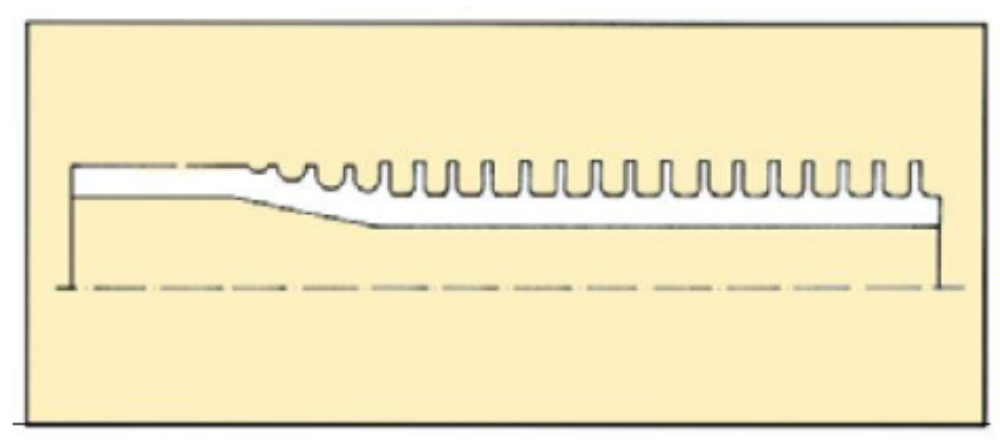

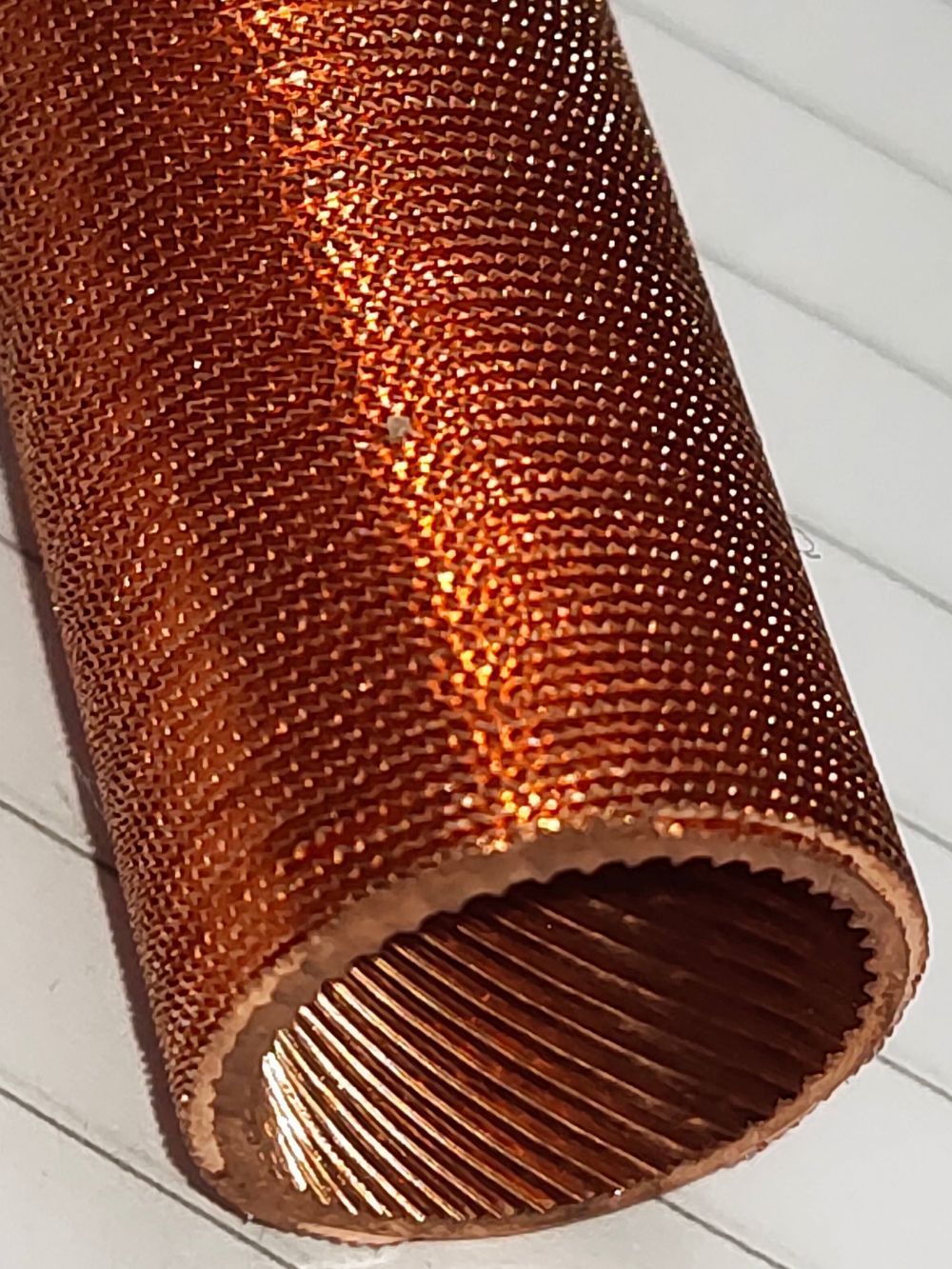

The Integral Low Fin Tubes is a tube where the external surface of the tube is enhanced by the process of finning and fins are drawn from the base material of the tube, resulting to increase in the surface area by 2.5 times than the plain tube area. The Extruded surface achieved through our manufacturing process is real and uniform.

Manufacturing Process:

Low fin (integral) tube is an extruded tube consisting of short low fins, the fins are rolled out from the outer wall of the plain tube by rollers, and the tube and fins are in the same piece of tube.

Integral Low Finned Tube(Copper Finned Tube) Advantages

Offers 2.5-3 times the external surface area of bare tube

Enhanced heat exchanger efficiency means less tube is required to accomplish the same heat transfer as a bare tube

Low finned tube can increase the performance of an existing exchanger without the difficult and expensive task of building new shells etc

Reduced space and weight can be extremely valuable in offshore production or high elevation distillation columns. Low finned technology can transform large shell and tube exchangers into compact heat exchangers

Low Finned Tube Properties

Low maintenance

Persistent against rust

Light weight

Integral Low fin tube Applications

Low finned tube is mainly used in air conditioning and refrigeration equipment in the condenser and evaporator absorption refrigeration oil cooler and other all kinds of heat exchanger,heat exchanger used in thermal power plants and nuclear power plants and evaporator, Marine switch in the condenser and evaporator used in gas turbine units and air cooler used for diesel

oil industry secondary cooler and cooler waste heat recovery system in various dryer and heater used in the heat exchanger in chemical industry.

Integral Low Fin Tube Specifications

| Product Specification | ||

| Tube OD | 12.7~31.75 (mm) | 1/4”~1 1/4”(NPS) |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.0118"~0.0197” |

| Fin Height | 0.9~1.3 (mm) | 0.0354”~0.0512” |

| Fin Pitch | 666~1111 FPM | 16~30 FPI |

| Fin Type | Integral Low | |

| Material | ||

| Tube Material | C.S., S.S., A.S., Copper, Titanium | |

| Applied | 415°C | |

Temperature | ||

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.