Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

DELLOK High Performance Copper Integral Finned Tube

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Product Description

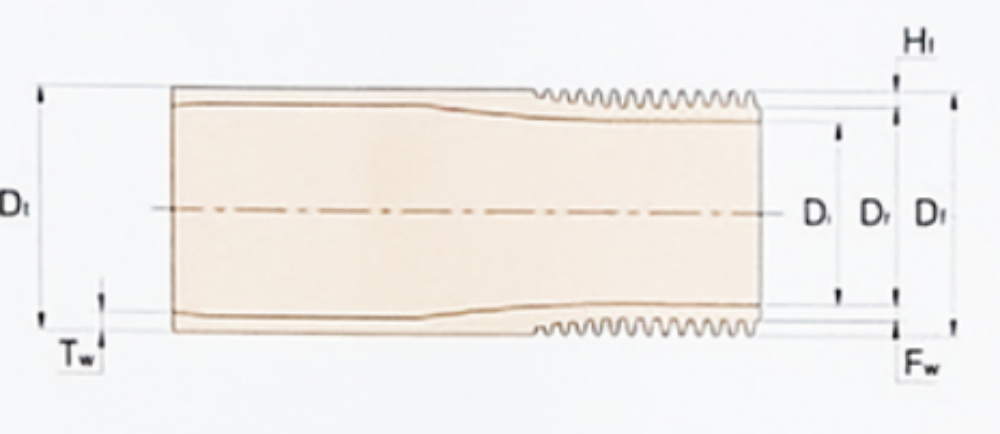

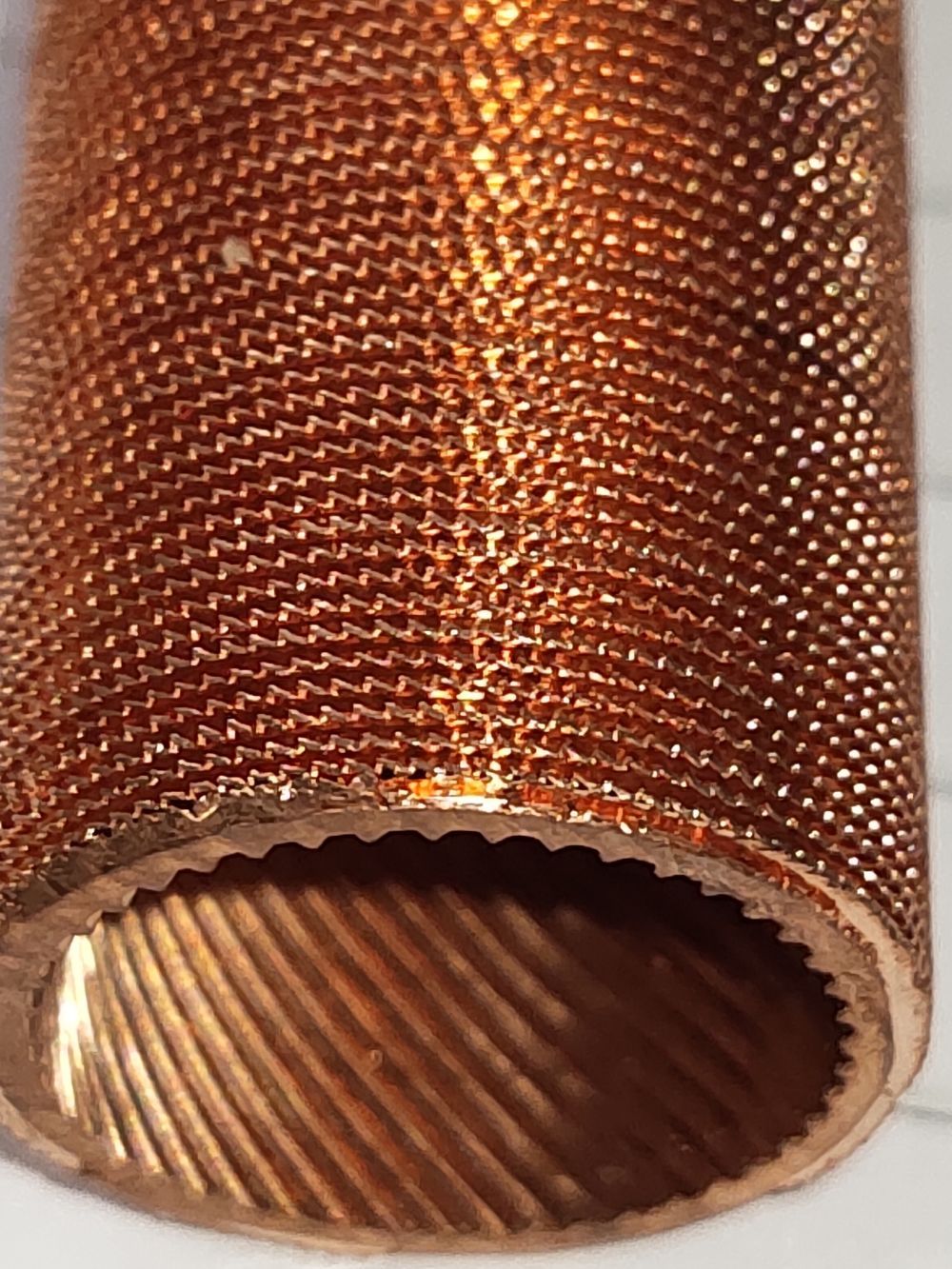

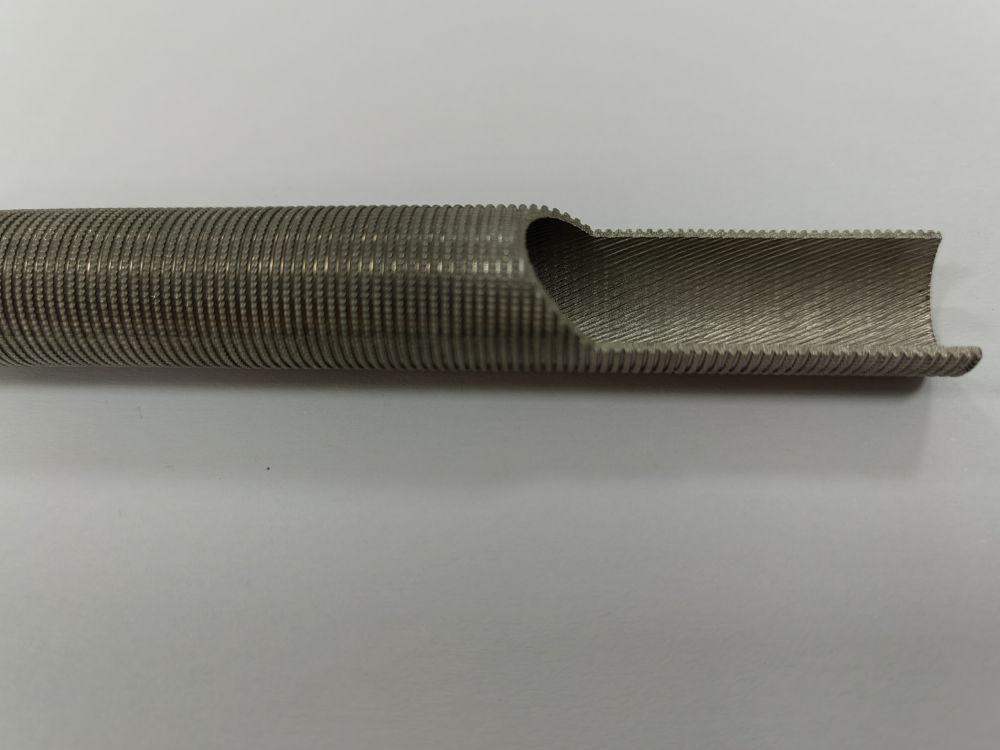

Low Fin Tube forming short fins in tube wall that greatly increase the surface area over smooth tube. The fins are Integral formed into the tube wall so the outside diameter of the fins are not larger than the pre-finned smooth tube.

Low finned tubes can be provided with a smooth or rifled tube inside surface.Some special work condition added rifling grooves of inside the tube promote turbulent flow and better heat transfer through the tube wall.

Low Fin Tube Manufacturing Process:

The fins are rolled out of the wall of the plain tube by use of a pass roller. Tube and fin consist of same piece.

Integral Low Finned Tube Advantages

Proven solution in a wide range of applications

Increased heat transfer surface compared to plain tubes

Material savings due to reduced tube length

Filling quantity reduction due to higher efficiency

Low Finned TubeProperties:

Manufacturing Process:- Cold Rolling of Fin on the Base tube Itself.

Fin To Tube Bond:- NA (fin is made from the base tube itself)

Heat Transfer Efficiency:- Good

Mechanical Resistance: – Good

Corrosion Protection: – Moderate

Temperature Range:- Up to Maximum 415 Deg C

Integral Low Fin Tube Specifications

| Product Specification | ||

| Tube OD | 12.7~31.75 (mm) | 1/4”~1 1/4”(NPS) |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.0118"~0.0197” |

| Fin Height | 0.9~1.3 (mm) | 0.0354”~0.0512” |

| Fin Pitch | 666~1111 FPM | 16~30 FPI |

| Fin Type | Integral Low | |

| Material | ||

| Tube Material | C.S., S.S., A.S., Copper, Titanium | |

| Applied | 415°C | |

Temperature | ||

FAQ

Q1: Are you trading company or manufacturer?

A: We are manufacture factory and we can accept OEM order. Welcome to visit our factory and check our products.

Q2: Can I have a sample ?

A: Yes, welcome to place sample order to test and check quality. Mixed samples are also OK.

Q3: What is your the lead time for production?

A: Generally Sample needs 1-3 days, mass production needs 15-30 days, also depends on your request.

Q4: What is the warranty for your products?

A :We provide one year warranty for the products.

Q5: What payment terms do you accept?

A :Trade assurance,TT,Western Union.

Q6: What are the modes of transportation of machines?

A: Air freight, sea freight express delivery, etc. We will choose the most suitable transportation method according to your requirements.Low fin Tube