Dellok Yonghui Radiating Pipe Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

Dellok Copper Alloy Titanium Integral Low Fin Tube

About Us

DELLOK (YONGHUI RADIATING PIPE MANUFACTURING CO.,LTD.) was established in 2002, which is located in Jiangsu, China. After many years of development, the company now has 66 million yuan in fixed assets, more than 200 employees, and 33 technical staffs. We have 4 aluminum processing production lines, with the annual processing capacity of more than 20,000 tons; And we have 5 tube-drawing production lines; 47 fintube production lines, 1 imported production line from American with the brand of McElroy , with the annual production capacity of 12 million meters the above. Quality is the theme of eternal pursuit of winner -Production workshop- Meticulous works, standardized management system and systematic quality assurance are Dellok(YONGHUI)'s best commitment to quality. In Dellok(YONGHUI), the quality control is not only the detection of the final process, but throughout the entire production process. We implement a set of quality control and assurance systems. Each batch of pipes is sampled and tested, and records are kept as a quality guarantee for the final product.

Product Description:

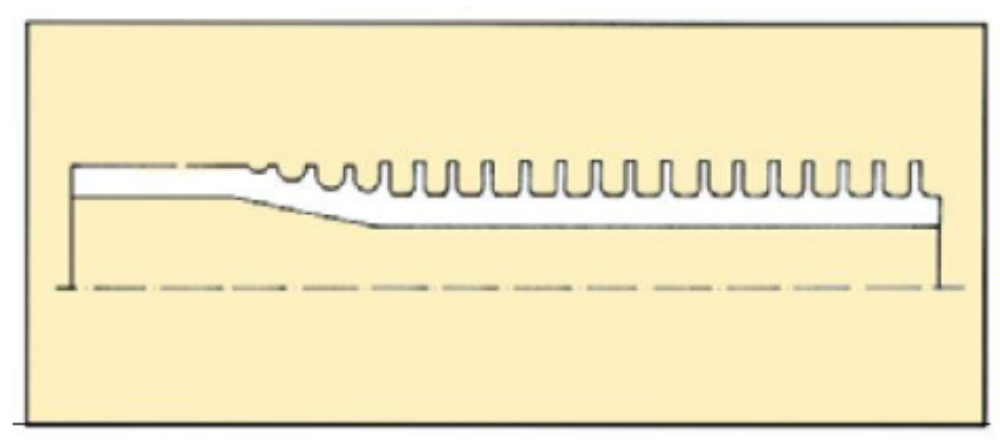

Integral lowfin tube developed as a method of increasing heat transfer performance of fluids while minimizing the size also cost of the Heat Exchanger. The fin tubes can improve the thermal performance of a heat exchanger without change shell size, flow arrangement or re-positioning of tube. The external surface of the tube is increased by the formation of "low fins".The fin is produced by being rolled from the wall of the tube and is therefore integral with the tube itself. Due to fin rolling the wall thickness beneath the finned section is reduced compared with the plain ends. The bore of the fin section is slightly reduced. Most tubular materials can be finned, however hardness of the material usually determines whether the tubes suitable for finning.Integral low fin tube developed as a method of increasing heat transfer performance of fluids while minimizing the size also cost of the heat exchanger. The fin tubes can improve the thermal performance of a heat exchanger without change shell size, flow arrangement or re-positioning of tube. The external surface of the tube is increased by the formation of "low fins".The fin is produced by being rolled from the wall of the tube and is therefore integral with the tube itself. Due to fin rolling the wall thickness beneath the finned section is reduced compared with the plain ends. The bore of the fin section is slightly reduced.

Most tubular materials can be finned, however hardness of the material usually determines whether the tubes suitable for finning.

Integral Low Fin Tube Applications:

Gas Coolers

Power Plants

Heat Recovery Steam Generators Condensers and Evaporators

Oil Coolers

Petrochemical Industries

Shell and tube type heat exchangers handling media such as water, steam, oils process air, gases etc.

Refrigeration Applications

Marine Applications

Economizers

Other various Heat exchanger applications

Integral Low Fin Tube Specifications:

| Product Specification | ||

| Tube OD | 12.7~31.75 (mm) | 1/4”~1 1/4”(NPS) |

| Tube Wall Thk | 1.65~3.0 (mm) | 0.065”~0.118” |

| Tube Length | ≤18,500 (mm) | ≤60.7 ft |

| Fin Thk | 0.3~0.5 (mm) | 0.0118"~0.0197” |

| Fin Height | 0.9~1.3 (mm) | 0.0354”~0.0512” |

| Fin Pitch | 666~1111 FPM | 16~30 FPI |

| Fin Type | Integral Low | |

| Material | ||

| Tube Material | C.S., S.S., A.S., Copper, Titanium | |

| Applied | 415°C | |

| Temperature | ||

FAQ

1. How are low fin tubes made?

Low finned tubes involve rotational processing of the outer surface of steel tubes to create a fin shape. A steel pipe length of 25.4 mm (1 inch) per fin and 19 fins is a design often used. We can also produce units with 26 fins.

2.What are advantages of integral low finned tubes?

Provides 2.5 to 3 times the external surface area of bare tube

Reduced capital cost for new equipment

Reduced retrofitting cost for existing equipment

Space, weight & structural savings

More materials & alloys to select

Reduced maintenance & life cycle cost

3. Where are integral low finned tubes used?

Low finned tubes are a reliable solution for controlling the temperature of gases and liquids, or for evaporating and condensing refrigerants. Thanks to their larger heat transfer surface area, they offer considerable potential to save in terms of materials and fill volumes, especially applicable to air and other gases on the fin-side and a fluid on the tube-side. Applied in heat exchanger for oil refinery and petrochemical plants, condenser and heat exchanger for petrochemical plants, condenser & evaporator for power plants.