ZHENGZHOU SHENGHONG HEAVY INDUSTRY TECHNOLOGY CO., LTD. |

|

Verified Suppliers

|

|

NPK Compound Fertilizer Production Line , NPK Production Line

Introduction For Compound Fertilizer Production Line

(1) a composite organic fertilizer is the key equipment maker fertilizer industry.

(2) suitable for cold granulation of fertilizer and high mass production in low concentrations.

(3) a machine housing with special rubber sheet lining or acid stainless steel plate,broach replace traditional equipment, automatically go to scar tumor

(4) High spheroidization strength, good appearance, corrosion resistance, wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc.

Description For Compound Fertilizer Production Line

1, we provide stand-alone, such as material mill, material mixer, fertilizer dryer, fertilizer cooling machines. We can also offer the entire line of compound fertilizer pellet production line.

2, chemical fertilizer raw materials is a single variety of chemical fertilizer.

3, an organic fertilizer pellet production line comprises a feed grinding, mixing, granulating, drying, cooling, packaging.

Raw Material For Compound Fertilizer Production Line

Compound fertilizer is the fertilizer containing two or all three of the three basic plant nutrients—Nitrogen, Phosphorus, and Potassium, as well as microelements, such as B, Mn, Cu, Zn, and Mo. The raw material can be powder or bulk, mostly are as below:

| Nitrogen | Phosphorus | Potassium | |

| Calcium nitrate | urea | Single superphosphate | Kainit |

| Ammonium bicarbonate | Ammonium chloride | Rock phosphate | Potassium chloride |

| Nitrate of soda | Ammonium sulphate nitrate | Dicalcium phosphate | Potassium sulphate |

| Ammonium sulphate | Ammonium nitrate | Triple superphosphate | Potassium nitrate |

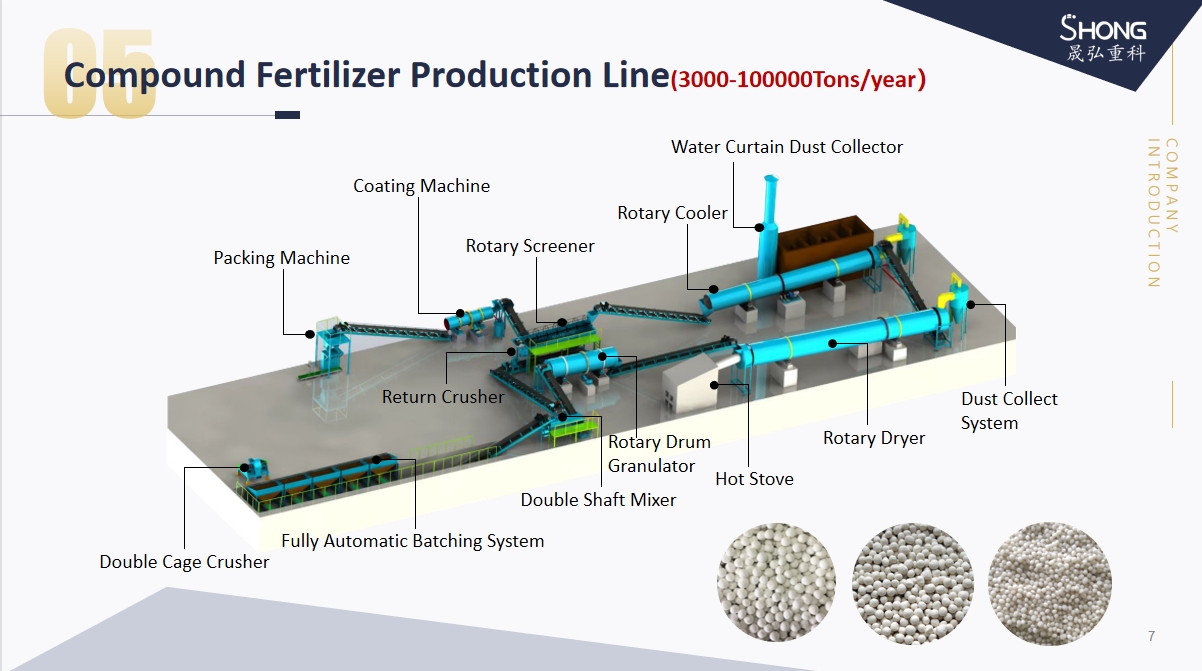

Flow Chart For Compound Fertilizer Production Line

Compound fertilizer production line usually includes 9 processes, batching, grinding, mixing, granulating, drying, cooling, screening, coating and packaging. Batching, mixing, granulating, drying, and screening processes are necessary. Other processes are optional based on different capacity.

Main Equipments For Compound Fertilizer Production Line

| No. | Processes | Machines | Function of machines |

| 1 | Batching process | Automatic batching machine | Ratio raw materials by formula |

| 2 | Grinding process | Grinder | Grind granules to powder |

| 3 | Mixing process | Mixer | Mix powder evenly, If necessary, add water, or other micro-elements |

| 4 | Granulating process | Feeding machine | Feed mixed powder into granulator evenly |

| Granulator | Make mixed powder into fertilizer granules | ||

| 5 | Drying process | Dryer | Dry fertilizer granules to low moisture by hot air |

| Hot stove | Generate hot air to dryer | ||

| Cyclone | Collect dust from dryer | ||

| 6 | Cooling process | Cooler | Cool fertilizer granules to normal temperature |

| Cyclone | Collect dust from cooler | ||

| 7 | Screening process | Screener | Screen out required size from fertilizer granules |

| 8 | Coating process | Coating machine | Coat color, anti-blocking agent, microelements etc on fertilizer granules |

| 9 | Packaging process | Air compressor | Generate power to packaging machine |

| Packaging machine | Package fertilizer granules into bags |

Features For Compound Fertilizer Production Line

1 pelletizing extrusion granulator granulation, grinding, pelletizing New Process

2, the whole ball machine to control the particle size of the pore template, replacing the template according to the particle size.

3, the particles uniform, smooth, sleek, high strength, good fluidity.

4, fertilizer organic fertilizer more than 95%.

5, the entire machine using the original three-ball machine, complete low-temperature drying, cooling, screening the whole process.

6, low investment in equipment and operating costs. Microflora greater than 90% survival rate.

7, the machine housing or the use of special rubber sheet lining acid stainless steel plate.Broach replace traditional equipment, automatically go to scar tumor

8. High spheroidizing strength, good appearance, corrosion resistance, wear resistance, low energy consumption, long service life, convenient operation and maintenance, etc.