QINGDAO AORUI PLASTIC MACHINERY CO.,LTD1 |

|

Verified Suppliers

|

|

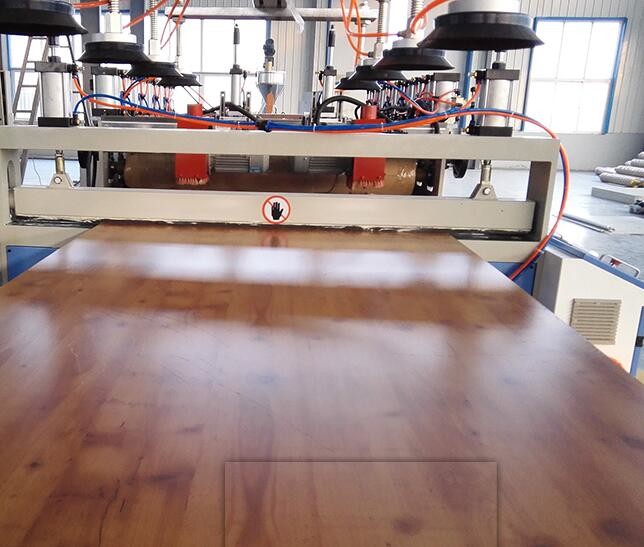

WPC Foam Board For Furniture Making Machine , Wood Composite Plastic Board Production Line , WPC Foam Board Machine

Quick detail:

1. PVC foam board machine:

Work flow:

Mixer→SJSZ series extruder→Coat-hanger type mould→Calibration

cooling platform→cooling rollers and edge-cutting device→Haul

off→stacker

2. Our plastic making machine can make many kinds of plastic productions like:PVC pipe,CPVC pipe,PE/HDPE/PE-RT pipe,PP-R pipe,plastic foamed profile,WPC profile and panel,wood plastic composite and so on.

Description:

1. Adopting the Celuka structural-foam process technology, compared with the free foamed board, the skinning foamed board has the features of flattening and smooth surface, strong skinning hardness and stiffness, and better mechanical property.

2. Complete process:

Raw material +wood power+ additive → mixing → granulating → conical

twin-screw extruder → profile extrusion mould → cool molding die →

vacuum cooling calibration table → belt haul-off → cutter → rack →

finished product →Recycling of unqualified products were broken

3. Application: High-grade cupboard, furniture, advertising materials, building decoration materials inner decorative materials for car, train and steamship. Decoration materials for car, train and steamship.

4. The wpc plate has the same characteristics as wood boards: which can enailed , can be sawed, can be drilled ,can be planed , can be sculptured. With the exclusive formula developed by our company, there is no need to granulate the material, which is cost savings and labor saving.

Specifications:

Model | SJSZ-51 | SJSZ-55 | SJSZ-65 | SJSZ-80 | SJSZ-92 |

Screw dia.(mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

Max speed(rmp) | 40 | 38 | 38 | 37 | 36 |

Main motor(kw) | 18.5 | 22 | 37 | 55 | 90 |

Capacity(kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

Center height(mm) | 1050 | 1050 | 1050 | 1050 | 1100 |

Net weight(kg) | 3000 | 3500 | 4000 | 5500 | 8000 |

L*W*H(m) | 3.6x1.1x2.1 | 3.6x1.1x2.1 | 4.2x1.5x2.4 | 4.7x1.5x2.4 | 6x1.6x2.5 |

Competitive Advantage: