QINGDAO AORUI PLASTIC MACHINERY CO.,LTD1 |

|

Verified Suppliers

|

|

PE WPC Bench Plastic Profile Extrusion Line , Parapet Profile Machine

Brief introduction of pvc profile machine:

1.This pvc ceiling making machines can be used to manufacture window profile and door profile, ceiling and wall panels, and other irregular shape profile widely used in home internal decoration.This machine for produce pvc wall panel can be designed according to the requests of clients.

2.This line features stable plasticization, high output,low sheering force,long life service and other advantages.

Description:

PE/PP WPC Wall Panel/Decking/Fence Plastic Profile Production Line

1.PE WPC floor profile is special for outdoor. This machine uses the special designed screw and barrel, die

and extrusion process to produce plastic and wood products.

2.The series of products are: One step thick plastic and wood plate extrusion machine, one step plastic and

wood profile extrusion machine, one step plastic and wood decoration plate extrusion machine, plastic and

wood pelletizing machine and different kinds of plastic and wood

dies.

3.This machine can use the one step extrusion method and also it can use the two-step extrusion method

after pelletizing. The two-step extrusion method can save the power and space, and the two-step extrusion

method features the machine can gain the high output and stable extrusion pressure.

4.A pre-heating feeder is mounted on the top of the extruder which extracts the humidity from the wood

powder, so that the feeding section of the extruder can be filled with enough material and the plastification

effect will be better.

5.Special and well designed screw enables the raw material to be evenly stay in the extruder. The screws

and barrel are bi-metallic treated, more wearable and

anti-corrosion.

6.feature:fire protection,moistureproof,water resistant,insect resistant,non deformation

wood powder material: Straw, flax, peanut shells,etc

advantage:environmental product,plasticizing uniform,long life.

raw material:wood powder with PE/PP,PP/PE can be recycled,additive material.

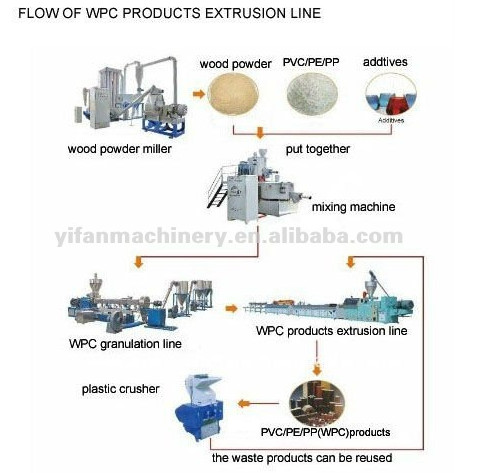

7.flow chart:

Applications:

1.field:outdoor,building,logistic,car,garden,home decoration,

2.product:pallet,wooden house,seat back,container plate,baseboard,building template,moisture-proof board,furniture,instrument panel,chair,tray,plank, cabin partition table,promotion board,etc.

3.application area:packaging,decoration,construction,logistics,gardens,municipal administration,traffic,sports,environmental protection,military,home furnishing,children’s toys

4. Available in different colors and wood grain design

5.Material is 100% recycled.

6. Complete process:

Milling → Mixing → Extruding → Mold → Calibrating → Hauling off→ Cutting→

Embossing,polishing,sanding→ Final product

Specifications:

| Model | Screw dia.(mm) | Ratio of screw length to dia. | Rational speed of screw(r/min) | Center height(mm) | Capacity(kg/h) | Motor power(kw) |

| SJ-30/25CY | 30 | 25:1 | 10-160 | 1000 | 19.5 | 2.2, 3 |

| SJ-30/28CY | 30 | 28:1 | 10-160 | 1000 | 21 | 2.2, 3 |

| SJ-45/25HY | 45 | 25:1 | 16-160 | 1000 | 35 | 5.5, 7.5 |

| SJ-45/28HY | 45 | 28:1 | 16-160 | 1000 | 40 | 7.5, 11 |

| SJ-65/25HY | 65 | 25:1 | 8-80 | 1000 | 100 | 18.5, 22 |

| SJ-65/30CY | 65 | 30:1 | 15-120 | 1000 | 120 | 22, 30, 37 |

| SJ-90/25HY | 90 | 25:1 | 10-100 | 1000 | 155 | 30, 45, 55 |

| SJ-120/25HY | 120 | 25:1 | 30-90 | 1000 | 250 | 75 |

Competitive Advantage:

1). Mainly used to produce the PVC window profiles, plastic decorative plates and PVC foam profiles

2). Use frequency conversion for speed regulation

3). Has super-taper twin-screw extruder with temperature controlling instrument in the screw core

4). Saves power by 30% - 40%

5). The rigid gear surface of the reducer can be operated continuously for a long time without trouble

6). Operation and mold changing are smooth and steady

7). Long usage life

8). Can produce steel plastic profiles by changing the wood imitation foaming profile mold, combines with one set of steel liner conveying devices.