Jiangsu Wulong Machinery Co., Ltd |

|

High Performance Feed Hammer Mill Machine , Feed Milling Production Line

High Performance Feed Hammer Mill Machine Water Drip structure Feed grinder machine Feed milling Production Line

1. Application and suitable scope

JFS2000MG hammer mill adapts “Dripping-shape” structure and it is the latest crushing technology and manufacturing process introduced from abroad. It is suitable for crushing many materials such as dried cassava, maize, bean cake, sorghum, soybean, conch and stem, which is widely used in the alcohol, grain, feedstuff, citric acid, starch and other industries.

2. Main specifications and technical parameters

| Item and Parameters | JFS2000-53MG | JFS2000-63MG | JFS2000-72MG | JFS2000-83MG | JFS2000-88MG | |

| Rotor diameter(mm) | 1142 | |||||

| Width of crusher chamber (mm) | 530 | 630 | 720 | 830 | 880 | |

| Spindle speed (r/min) | 1480 | |||||

| Driving type | Coupling drive | |||||

| Hammer quantity (pieces) | 72 | 72~132 | 108~180 | 144~216 | 180~252 | |

| Motor power (Kw) | 55~90 | 90~132 | 110~160 | 160~220 | 200~250 | |

Capacity (T/h) | Cassava | 9~15 | 15~20 | 18~25 | 20~28 | 23~30 |

| Maize | 6~10 | 10~16 | 14~18 | 18~23 | 20~25 | |

| Reference weight (kg) | 2300 | 3500 | 3800 | 4500 | 5200 | |

| Outline dimension (mm) | 2265X1615X1905 | 2370×1615×1905 | 2650×1615×1905 | 2750×1615×1905 | 2814×1615×1905 | |

Note:

1. The reference productivity in the above table is the crushing output when the crusher is with correct installation, good suction, the negative pressure under the sieve ≤ 700~1000Pa, standard high porosity sieve plate, and the moisture content ≤14%.

2.The productivity is only for model selection reference. If there is any special requirement, it can also be designed separately.

3. Main structure and working principle

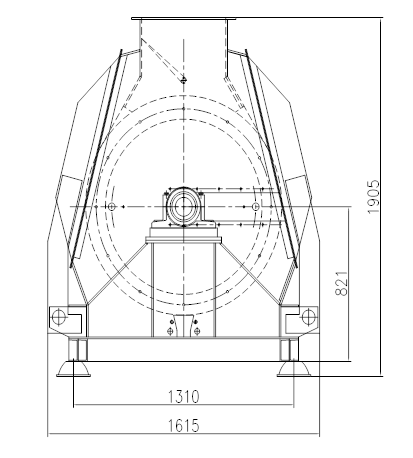

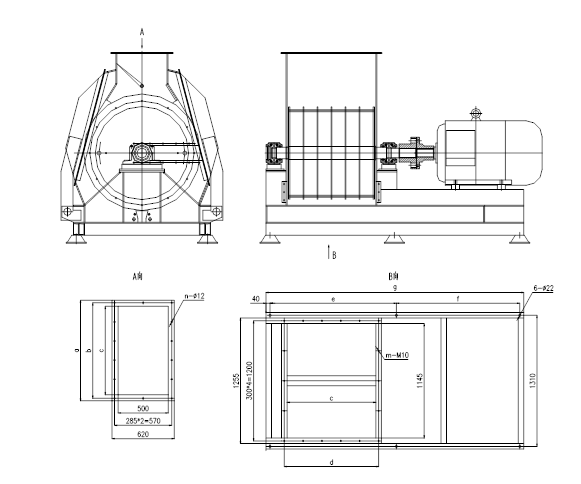

1) For structure diagram and installation foundation, please refer to Figure 1.

2) Working principle

Material is fed from the top inlet and will enter into the crushing chamber through the feeding guide mechanism. The material is struck by high speed rotating hammerer, so it is crushed by being rubbed and struck in cycles and cutting function of punching sieve. Meanwhile under the action of centrifugal force and air stream, the material of qualified granularity will pass through the sieve pore and discharge from the outlet under the base. Customer can adapt multiple auxiliary equipments to finish the work such as material collection, conveying and warehouse entry based on the specific process.

Figure1:

Figure2: JFS2000MG Installation dimensions

4. Operation

1,Operator should be familiar with the machine’s performance, understand its structure, and learn the Operation Instruction seriously.

2,Before starting the machine, check each connection part carefully, no looseness is allowed.

3,Check whether the rotor rotation is flexible and there should be no abnormal noise.

4,Increase feed quantity gradually after no load running for 2~3 minutes.

5,Before stop the machine, first stop feeding, discharge all the remaining material in the machine, and then it could be stopped.

6,The rotating direction of main shaft is determined by different feeding direction. The rotating direction of motor is controlled by manual direction control of guide mechanism. Before opening the door, power supply should be switched off. When the door is opened, crusher will stop and meanwhile the motor can not be started, to guarantee the safety and reliability when replacing damageable parts and doing maintenance. After maintenance is finished and the door is closed, put the handle of feed guide plate in the correct position in accordance with the needed rotation of motor.

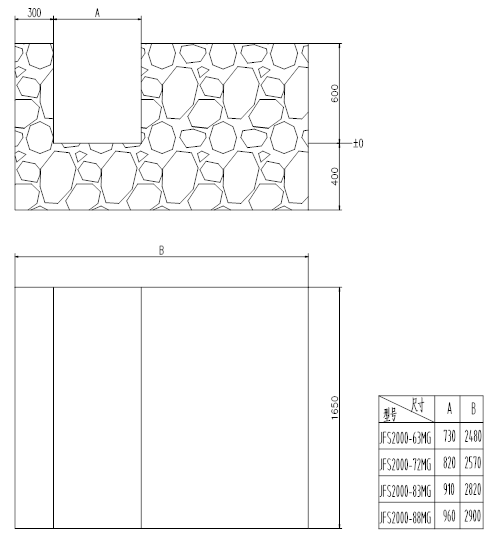

Figure 3: Installation foundation drawing of JFS2000MG serial

5,Maintenance and troubleshooting

1,Maintenance

<1>Operate strictly in accordance with the operation methods; every shift should do the necessary inspections and cleaning work.

<2>After the machine’s every working time of 4000-5000 hours, the bearings should be removed and washed once.

<3>Do repair or replacement immediately when the components are damaged or badly worn. The rotor should be taken for dynamic balance correction after repair or replacement.

<4>If the down time is long, both inside and outside of the machine should be cleaned up and remove the dustiness, to prevent corrosion and the sieve pore blocking.

<5>For long-term storage, the machine should be placed in a ventilated and dry place, and rain-proof measures should be taken when stored in the open air.

2,Method to remove troubles

| Symptom | Failure | Troubleshooting |

| 1.Difficult to start the motor | 1. Voltage is too low. 2. Wire sectional area is too small. 3. Fuse is easily burn-out. | 1. Start after the electricity usage peak. 2. Replace the proper wire. 3. Replace a fuse that is consistent with the motor capacity. |

| 2.Powerless and overheat of motor | 1. Motor does the two-phase operation. 2. Motor is of windings short circuit. 3. Long-term overload | 1. Turn off phase, three-phase operation. 2. Do motor repair 3. Work under rated load |

| 3.Strong vibration of the mill | 1. Mounting and arrangement of the hammers are wrong. 2. Weight difference of the two group corresponding hammers is too large. 3. Individual hammer is stuck, do not be thrown off. 4. Other parts of the rotor are of imbalance. 5. Bending of spindle 6. Damage of bearing 7. Failure of shock absorber | 1. Re-install as the hammer ordered drawing 2. Replace hammers, make the weight difference ≤5 g 3. Make hammer rotate flexibly 4. Do rotor balance 5. Do alignment or replace new shaft 6. Replace bearing 7. Replace shock absorber |

| 4.Abnormal noise of the crush chamber | 1. Iron, stone and other hard objects into the machine 2. Loss or damage of internal parts 3. The clearance between hammer and screen is too small. | 1. Stop to do hard objects removal 2.Stop to do inspection, do components replacement 3. Make the clearance meet the requirement |

| 5.Significant decrease of productivity | 1. Motor power is not enough. 2. Hammer is of serious abrasion. 3. Uneven material feeding 4. High moisture content of raw material 5. The size of sieve pore does not meet the requirements. 6. Small aperture ratio of sieve slice | 1. Check motor 2. Reverse end for end to use or replace new hammers 3. Do uniform feeding 4. Drying causes 5. Replace sieve plate with corresponding sieve pore 6. Replace sieve slice of high aperture ratio |

| 6.Regurgitate of feed port | 1. Blockage of conveying pipeline 2. Blockage of sieve pore | 1. Open up the blockage 2. Clean the sieve pore or replace the sieve plate |

| 7.Finished product is too rough. | 1. Sieve plate is of serious abrasion or holes. 2. Sieve plate and sieve frame are loosed fit, or the side clearance is too large. | 1. Fill holes or replace sieve plate 2. Stop to do inspection, make the sieve plate and sieve frame fit tight |

| 8.The bearing is overheating. | 1. The grease is too much, too little or not good. 2. Damage of bearing. 3. Bending of spindle or unbalance of rotor. 4. Work overload of a long-term | 1. Replace grease, add oil as required 2. Replace a new bearing 3. Do spindle alignment and rotor balance 4. Reduce the feeding quantity |

| 9.Noise of coupling | 1. Damage of elastic pin | 1. Replace new elastic pin |

Product Application

Our Hammer Mill is mainly applied to crushing corn, sorghum, wheat, beans, cakes of fine feed.