Shenzhen Fairtech Electronics Co.,LTD |

|

Verified Suppliers

|

ESD clothing made with FairtechTextiles fabrics is the best solution for protecting electronic components against ESD. Our Anti Static fabrics are certified to European Standards. These antistatic fabrics are specifically designed to prevent the ESD effect when working with electronics, high-explosive vapors, or in super-clean lab environments.

Antistatic fabric, also known as conductive fabric or ESD (Electrostatic Discharge) fabric, is a type of textile that is designed to dissipate or neutralize static electricity. It is commonly used in industries where static electricity can cause damage to sensitive electronic components or create safety hazards. Here's some information about antistatic fabric:

Why we need the Anti static fabric?

Antistatic fabrics play a crucial role in mitigating the risks associated with static electricity in various industries. By providing a controlled path for the dissipation of static charges, they help protect sensitive equipment, enhance safety, and maintain the integrity of electronic components and products.

Often referred to as "conductive silk", this special polyester filament fabric is made from high quality conductive yarns. It is suitable for making functional clothes such as coveralls, suits, jackets, caps, boots, etc. It has a good resistance to static, chemicals, and abrasion, and is designed for use in Class 1000 cleanrooms or higher.

It has a wide range of uses in the electronics, medical, biology, optics, and spaceflight industries and meets ESD standards, with a system resistance of 10e6-10e8Ω. ESD fabric prevents the accumulation of static electricity, and is made by either interweaving or separating the conductive fiber fabric during spinning. The conductive fiber fabric itself has either metal oxide or carbon black as an additive.

In terms of performance, the etymology of electricity of every cloth is <0.6μ c/pc when tested at 20± 5 ℃ and 30~40% humidity. Also, after being washed 100 times, the density average of fabric charge surface is ≤ 7.0μc/m2. Additionally, the washable fabric has a grade ≥33.0 h for A and ≥16.5 h for B in wear comfortability.

| Property | Description |

|---|---|

| Density | 188*120 |

| Thickness | Lightweight |

| Type | 5mm Grid/strip Fabric Or 4mm Grid/strip Fabric |

| Applicable to the Crowd | Women, Men, GIRLS, BOYS |

| Material | Polyester / Cotton, 98% Polyester+2% Conductive Filament |

| Static Decay | 0.1s |

| Flexibility | Good |

| Surface Resistance | 10^6-10^9Ω |

| Sample | Availalbe |

| Weight | 200-400g/m2 |

| Keywords | ESD fabric cloths, conductive fabric, antistatic fabric, ESD garment |

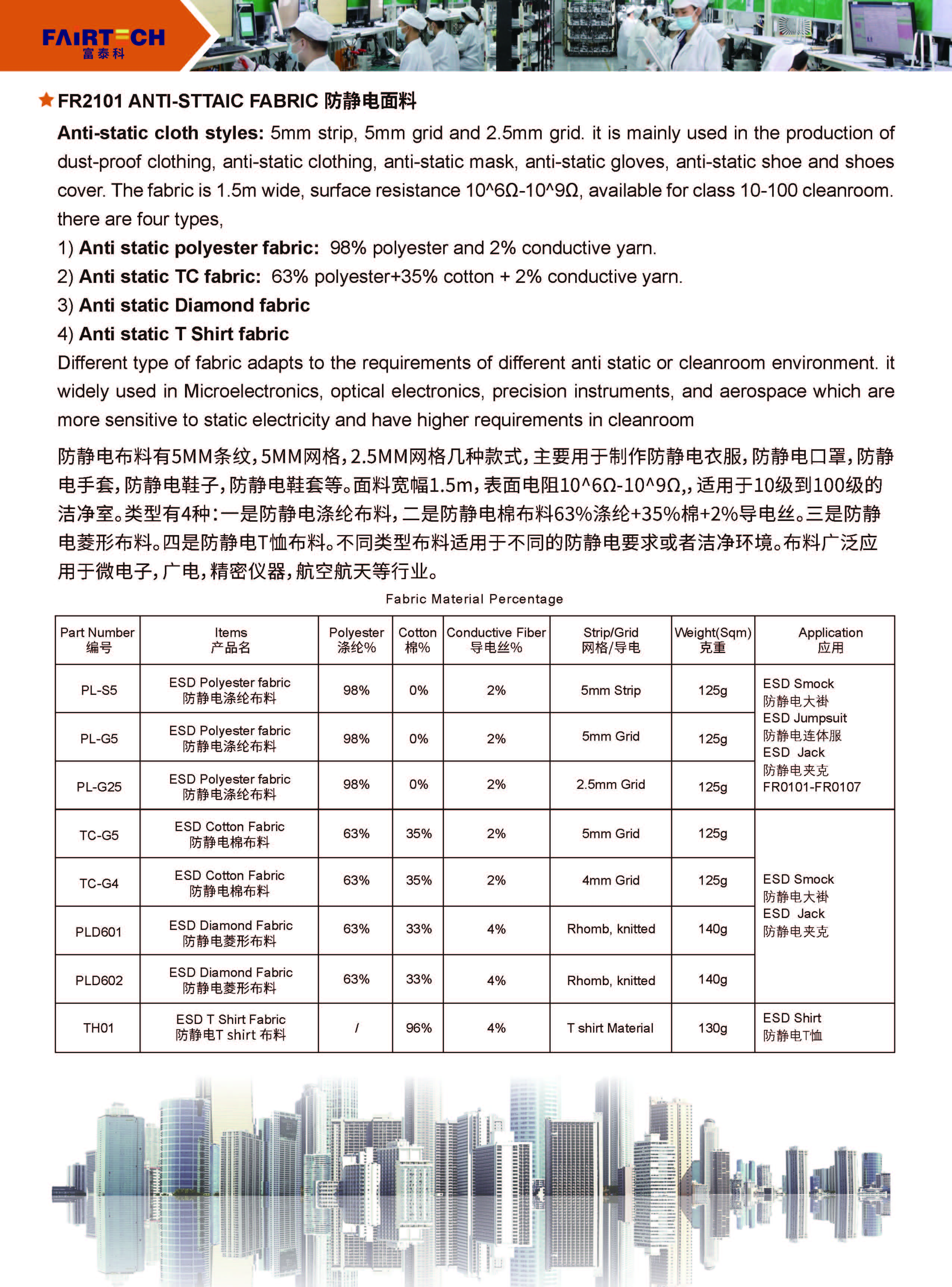

Fairtech FR2101 Anti Static ESD Fabrics are designed to provide superior electrical conductivity and protect sensitive electronic components from static electricity. This highly durable fabric is certified with CE and ISO and available in various styles such as TWILL, Antistatic, 5mm Grid/Strip Fabric, and 4mm Grid/Strip Fabric. It is primarily used for making jackets, shirts, bags, blankets, caps, curtains, dresses, garments, shoes, suits and more. With a density of 188*120, these fabrics come in various weights ranging from 200-400g/m2.

The fabric boasts excellent anti-static properties and is constructed using the highest quality materials to ensure long-lasting performance. It can be ordered in minimum of 100 meters and costs USD1.1/Meter. The fabric is packaged in rolls containing 100-130 meters and delivered within 3-5 days. It is accepted for payment through L/C, D/A, D/P, T/T, Western Union, or MoneyGram.

Fairtech FR2101 Anti Static ESD Fabrics are ideal for use in electronics, semiconductor, aerospace, and automotive industries. It comes with a guaranteed supply of 10000000meter per week.

Our technical support and services for Anti Static ESD Fabrics include:

Q1. What is ESD level?

A1: ESD Classes

ESD Class Sensitivity

ESD Class 0 <250 Volts

ESD Class 1 250 to 1999 volts

ESD Class 2 2000 to 3999 volts

ESD Class 3A 4000 to 7999 volts

Q2: What is anti-static, conductive, or dissipative?

A2: :Antistatic - Refers to the property of a material that inhibits triboelectic charge generation effects. Triboelectric charge is basically static electricity.

Static Dissipative - Material which will rapidly dissipate electrostatic charges over its surface or volume, having a resistivity range between conductive and insulative.

Conductive - Materials defined as being either surface or volume conductive. Such materials may be either metal or impregnated with metal, carbon particles, or other conductive ingredients or whose surface has been treated with such materials through a process of lacquering, plating, metallizing, or printing.

Q3. Why is ESD used?

A3: More specifically, ESD equipment is intended to: Prevent the buildup of static electricity. Safely discharge any static electricity that gets generated. Protect people and products from the effects from an accidental discharge.

Q4. What is the difference between antistatic and ESD?

A4: Anti-static floors usually have a coating or chemical additive that dissipates static across its surface so that you never build up enough charge to get a shock. ESD is a much more robust solution that delivers more consistent, long-term results because it's actually earthed.

Q5. What are 4 ways to prevent ESD?

A5: Keep electrostatic-sensitive parts in their containers until they arrive at static-protected workstations. Place parts in a static-protected area before removing them from their containers. Avoid touching pins, leads, or circuitry. Always be properly grounded when touching a static-sensitive component or assembly.

Q6. How important is ESD protection?

A6: ESD protection is a vital consideration when working with sensitive electronic components and assemblies. ESD stands for electrostatic discharge and refers to sudden releases of built-up static electricity. This common phenomenon can damage electronic parts if not guarded against.