Shenzhen Fairtech Electronics Co.,LTD |

|

Verified Suppliers

|

|

ESD clothing made with FairtechTextiles fabrics is the best solution for protecting electronic components against ESD. Our Anti Static fabrics are certified to European Standards. These antistatic fabrics are specifically designed to prevent the ESD effect when working with electronics, high-explosive vapors, or in super-clean lab environments.

What is Antistatic Fabric?

Antistatic fabric, also known as conductive fabric or ESD

(Electrostatic Discharge) fabric, is a type of textile that is

designed to dissipate or neutralize static electricity. It is

commonly used in industries where static electricity can cause

damage to sensitive electronic components or create safety hazards.

Here's some information about antistatic fabric:

Why we need the Anti static fabric?

Uncontrolled release from static build-up is a potential hazard in

many industries, especially where combustible fuels, gases and

dusts are present. It is also equally hazardous to the safe

assembly of sensitive components in clean rooms and the operation

and maintenance of electronic equipment and controls. One of the

most serious risks is from the human body, which is capable of

generating up to 40,000 volts of static electricity. ESD occurs

when two materials come into contact and then separate, resulting

in a spark discharge when a metallic (conductive) object is

touched. This discharge can potentially damage electronic circuits,

precision machinery, and even cause gas explosions. To prevent ESD

and discharge static electricity in the air, antistatic fibers are

woven into the fabric:

| Use | Tear Strength (N) |

|---|---|

| Jacket, Shirt, Bag, Blanket, Cap, Curtain, Dress, Garment, Industry, Shoes, Suit | 20-30 |

| Type | Width (in) |

| 5mm Grid/strip Fabric Or 4mm Grid/strip Fabric | 58/60 |

| Feature | Weight (g/m2) |

| Anti-Static, Shrink-Resistant, Sustainable, Tear-Resistant | 200-400 |

| Density | Permeability to Water (g/hr) |

| 188*120 | 55.00 To 60.00 |

| Sample | Surface Resistance (Ω) |

| Available | 10^6-10^9 |

Antistatic fabrics have a wide range of applications across various industries where static electricity control is highly essential. Some of the common uses are mentioned below:

To protect sensitive electronic components from electrostatic discharge, antistatic fabrics are used to manufacture protective clothing, gloves, and garments for personnel.

In order to avoid static buildup and potential hazards during vehicle assembly, antistatic fabrics are utilized in producing seating materials and protective clothing.

To limit static electricity and safeguard delicate equipment or products, antistatic fabrics are utilized in cleanrooms and sterile environments, in both pharmaceuticals and healthcare sectors.

Workers dealing with detonable materials or combustible substances make use of antistatic fabrics clothing and equipment to avoid static discharge and possible ignition.

Antistatic fabrics usually preserve their antistatic and conductive properties throughout their service life. However, to obtain continuous performance, it is essential to adhere to manufacturer guidelines for suitable upkeep and maintenance. Antistatic fabrics may necessitate explicit washing, drying, and handling instructions to prevent damage to their conductive properties.

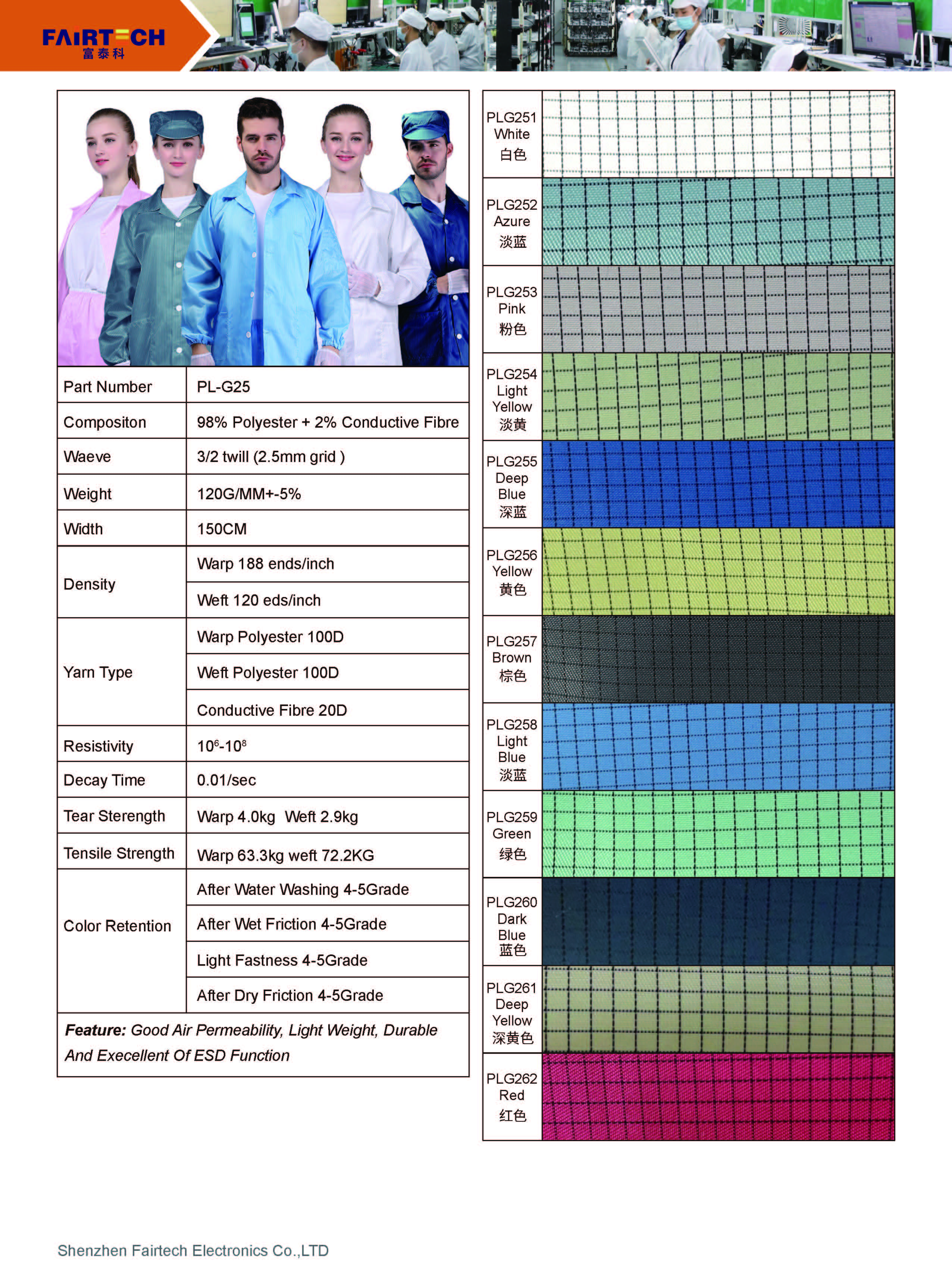

Brand Name: Fairtech

Model Number: FR2101

Place of Origin: China

Certification: CE,ISO

Minimum Order Quantity: 100 Meter

Price: USD1.1/Meter

Packaging Details: 100-130meter/roll

Delivery Time: 3-5days

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: 10000000meter per Week

Color: White, Blue, Pink, Yellow, Green And Etc

Style: Other, TWILL, Antistatic

Surface Resistance: 10^6-10^9Ω

Width: 58/60

Type: 5mm Grid/strip Fabric Or 4mm Grid/strip Fabric

Are you looking for the best quality conductive fabric, antistatic fabric, ESD fabric cloths for your ESD application? Fairtech's Anti Static ESD Fabrics come with CE,ISO certification, minimum order quantity of 100 Meter and price of USD1.1/Meter. We supply 10000000meter per week in various colors like White, Blue, Pink, Yellow, Green and etc. It is available in two styles, Other, TWILL, Antistatic and surface resistance of 10^6-10^9Ω. The Anti Static ESD Fabrics are available in width of 58/60 and type of 5mm Grid/strip Fabric Or 4mm Grid/strip Fabric. The packaging details are 100-130meter/roll and delivery time is 3-5days. We accept payment through L/C, D/A, D/P, T/T, Western Union, MoneyGram.