Shenzhen Fairtech Electronics Co.,LTD |

|

Verified Suppliers

|

|

ESD clothing made with FairtechTextiles fabrics is the best solution for protecting electronic components against ESD. Our Anti Static fabrics are certified to European Standards. These antistatic fabrics are specifically designed to prevent the ESD effect when working with electronics, high-explosive vapors, or in super-clean lab environments.

Antistatic fabric, also known as conductive fabric or ESD (Electrostatic Discharge) fabric, is a type of textile that is designed to dissipate or neutralize static electricity. It is commonly used in industries where static electricity can cause damage to sensitive electronic components or create safety hazards. Here's some information about antistatic fabric:

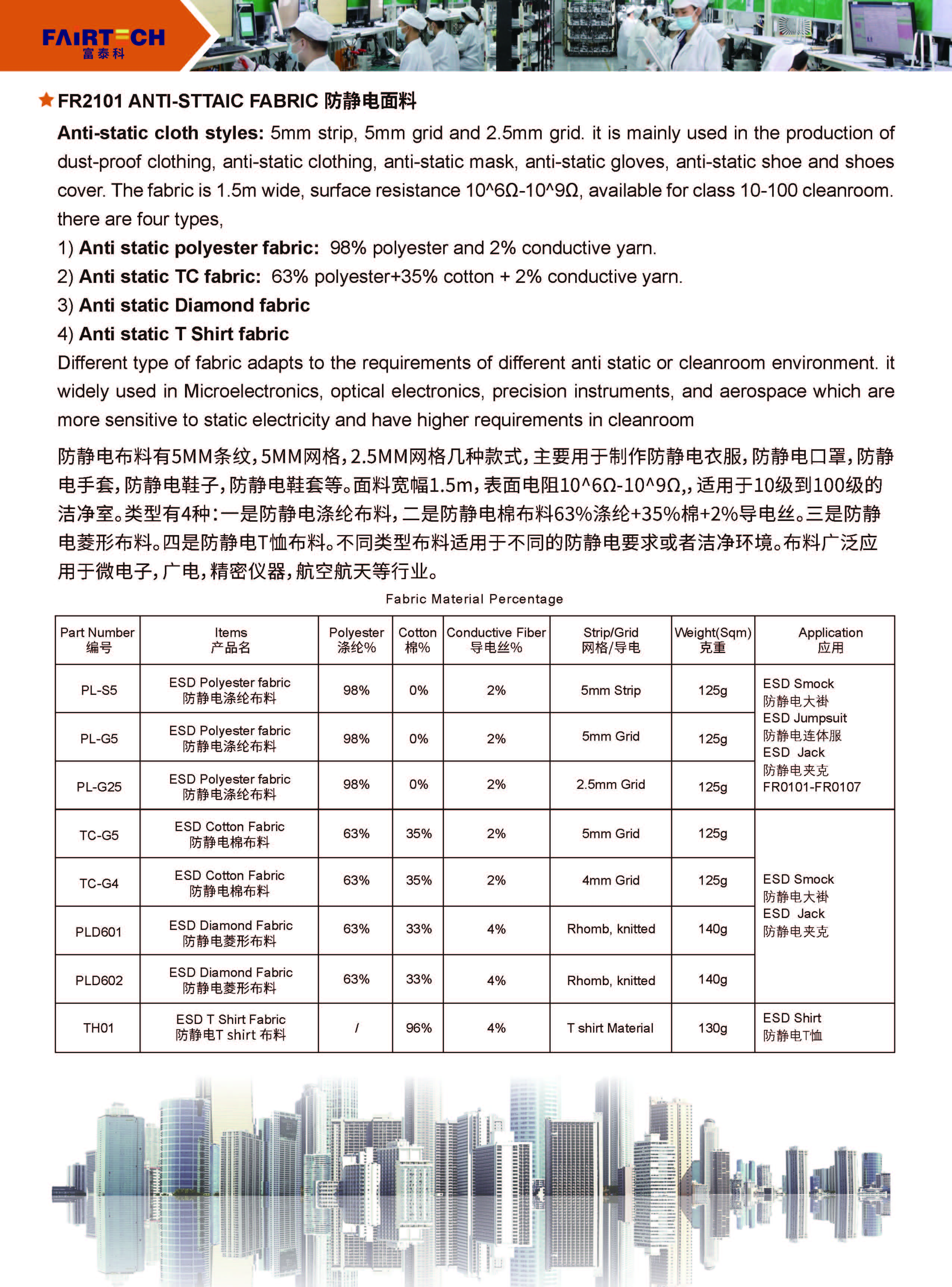

Anti-static cloth styles: 5mm strip, 5mm grid and 2.5mm grid. it is mainly used in the production of dust-proof clothing, anti-static clothing, anti-static mask, anti-static gloves, anti-static shoe and shoes cover. The fabric is 1.5m wide, surface resistance 10^6Ω-10^9Ω, available for class 10-100 cleanroom. there are four types,

Different type of fabric adapts to the requirements of different anti static or cleanroom environment. it widely used in Microelectronics, optical electronics, precision instruments, and aerospace which are more sensitive to static electricity and have higher requirements in cleanroom.

Why we need the Anti static fabric ?

Conductive silk fabric is also known as “conductive silk”, and is made up of special polyester filament and high quality conductive yarns.

It can be used to sew a variety of functional garments, such as coveralls, suits, jackets, caps, boots, and more.

It provides good resistance to static electricity, chemicals, and abrasion. Conductive silk fabric is designed for Class 1000 cleanrooms and higher.

This kind of fabric has various applications in electronics, medicals, biology, optics, spaceflight industries, and more. It complies with ESD safety standards with a system resistance of 10e6-10e8Ω.

Conductive silk fabric is designed to prevent the accumulation of static electricity on clothes. This is achieved through the separation or fusion of conductive fiber fabric when spinning.

The fabric is made up of composite spun metal oxide or carbon black. Its performance parameters are as follows: Under the temperature of 20 ± 5℃ and humidity 30 - 40%, the fabric charge surface has an average density of ≤7.0μc/m2 after 100 washes. The electricity etymology of every cloth is <0.6μc/pc. Lastly, the fabric is washable with grade A having a lifespan ≥33.0h and grade B having a lifespan ≥16.5h.

| Property | Value |

|---|---|

| Width | 58/60 |

| Sample | Available |

| Use | Jacket, Shirt, Bag, Blanket, Cap, Curtain, Dress, Garment, Industry, Shoes, Suit |

| Color | White, Blue, Pink, Yellow, Green And Etc |

| Function | Antistatic |

| Style | Other, TWILL, Antistatic |

| Thickness | Lightweight |

| Density | 188*120 |

| Material | Polyester / Cotton, 98% Polyester+2% Conductive Filament |

| Flexibility | Good |

Antistatic fabrics are widely used in various industries for static electricity control.

Common applications include electronics and semiconductor manufacturing, automotive industry, pharmaceutical and healthcare sectors, and explosives and flammable substance handling.

Antistatic fabrics are used to make garments, gloves, and cleanroom clothing for personnel to prevent electrostatic discharge that can damage sensitive electronic components in electronics and semiconductor manufacturing. In the automotive industry, antistatic fabrics are utilized in the production of seating materials and protective clothing to prevent static buildup and potential hazards during vehicle assembly. In the pharmaceutical and healthcare sectors, antistatic fabrics are used in cleanrooms and sterile environments to minimize static electricity and protect sensitive equipment or products. In manufacturing and handling of explosives and flammable substances, antistatic fabrics are employed to prevent static discharge and potential ignition.

Antistatic fabrics generally maintain their conductivity and antistatic properties throughout their useful life. However, proper care and maintenance is necessary to ensure continued performance. Manufacturer guidelines for washing, drying, and handling should be followed to prevent any damage to the conductive properties.

Brand Name: Fairtech

Model Number: FR2101

Place of Origin: China

Certification: CE,ISO

Minimum Order Quantity: 100 Meter

Price: USD1.1/Meter

Packaging Details: 100-130meter/roll

Delivery Time: 3-5days

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: 10000000meter per Week

Density: 188*120

Flexibility: Good

Tear Strength: 20-30N

Type: 5mm Grid/strip Fabric Or 4mm Grid/strip Fabric

Static Decay: 0.1s

Fairtech FR2101 Fabric Antistatic ESD is the perfect product for those looking for a fabric antistatic solution. This antistatic fabric from Fairtech has a static decay time of 0.1s, and features a density of 188*120. Additionally, this product has good flexibility and a tear strength of 20-30N. It is available in either a 5mm grid/strip fabric or a 4mm grid/strip fabric.

Fairtech FR2101 Fabric Antistatic ESD is certified by CE and ISO, and requires a minimum order quantity of 100 meters. The price for this product is USD1.1 per meter, and it is supplied in rolls of 100-130 meters. Delivery times are 3-5 days, and payment terms include L/C, D/A, D/P, T/T, Western Union, and MoneyGram.

If you are looking for a reliable fabric antistatic solution, look no further than Fairtech FR2101 Fabric Antistatic ESD. With its excellent static decay time, good flexibility, and tear strength, this product is the perfect choice. With a supply capacity of up to 10000000 meters per week, you can be sure that your order will be fulfilled on time. Contact us today to place your order and get the best fabric antistatic solution on the market.

Q1. What is ESD and non ESD?

A1: ESD stands for “electrostatic discharge”. Unlike anti-static, electrostatic discharge is not dangerous for people themselves, but is dangerous for very sensitive electronic components. People can generate dangerous voltages through friction, electrostatic induction or contact build-up.

Q2. What is the meaning of anti static cloth?

A2: This type of professional clothing is made using fibres that stretch rather than break. These fibres are synthetics combined with plastics and rubber to ensure that they stretch and generate as little static electricity as possible.

Q3. Why is ESD used?

A3: More specifically, ESD equipment is intended to: Prevent the buildup of static electricity. Safely discharge any static electricity that gets generated. Protect people and products from the effects from an accidental discharge.

Q4. What is ESD protection?

A4: Protection against electrostatic discharges (ESD) is part of EMC Immunity (Electro Magnetic Compatibility) requirements. It is the ability for equipment to properly operate in its electromagnetic environment by limiting the reception of electromagnetic energy that may cause physical damage.

Q5. What is the difference between antistatic and ESD?

A5: Anti-static floors usually have a coating or chemical additive that dissipates static across its surface so that you never build up enough charge to get a shock. ESD is a much more robust solution that delivers more consistent, long-term results because it's actually earthed.