Shenzhen Fairtech Electronics Co.,LTD |

|

Verified Suppliers

|

|

ESD clothing made with FairtechTextiles fabrics is the best solution for protecting electronic components against ESD. Our Anti Static fabrics are certified to European Standards. These antistatic fabrics are specifically designed to prevent the ESD effect when working with electronics, high-explosive vapors, or in super-clean lab environments.

Antistatic fabric, also known as conductive fabric or ESD (Electrostatic Discharge) fabric, is a type of textile that is designed to dissipate or neutralize static electricity. It is commonly used in industries where static electricity can cause damage to sensitive electronic components or create safety hazards. Here's some information about antistatic fabric:

Different type of fabric adapts to the requirements of different anti static or cleanroom environment. It is widely used in microelectronics, optical electronics, precision instruments, and aerospace which are more sensitive to static electricity and have higher requirements in cleanroom.

Why do we need the Anti static fabric?

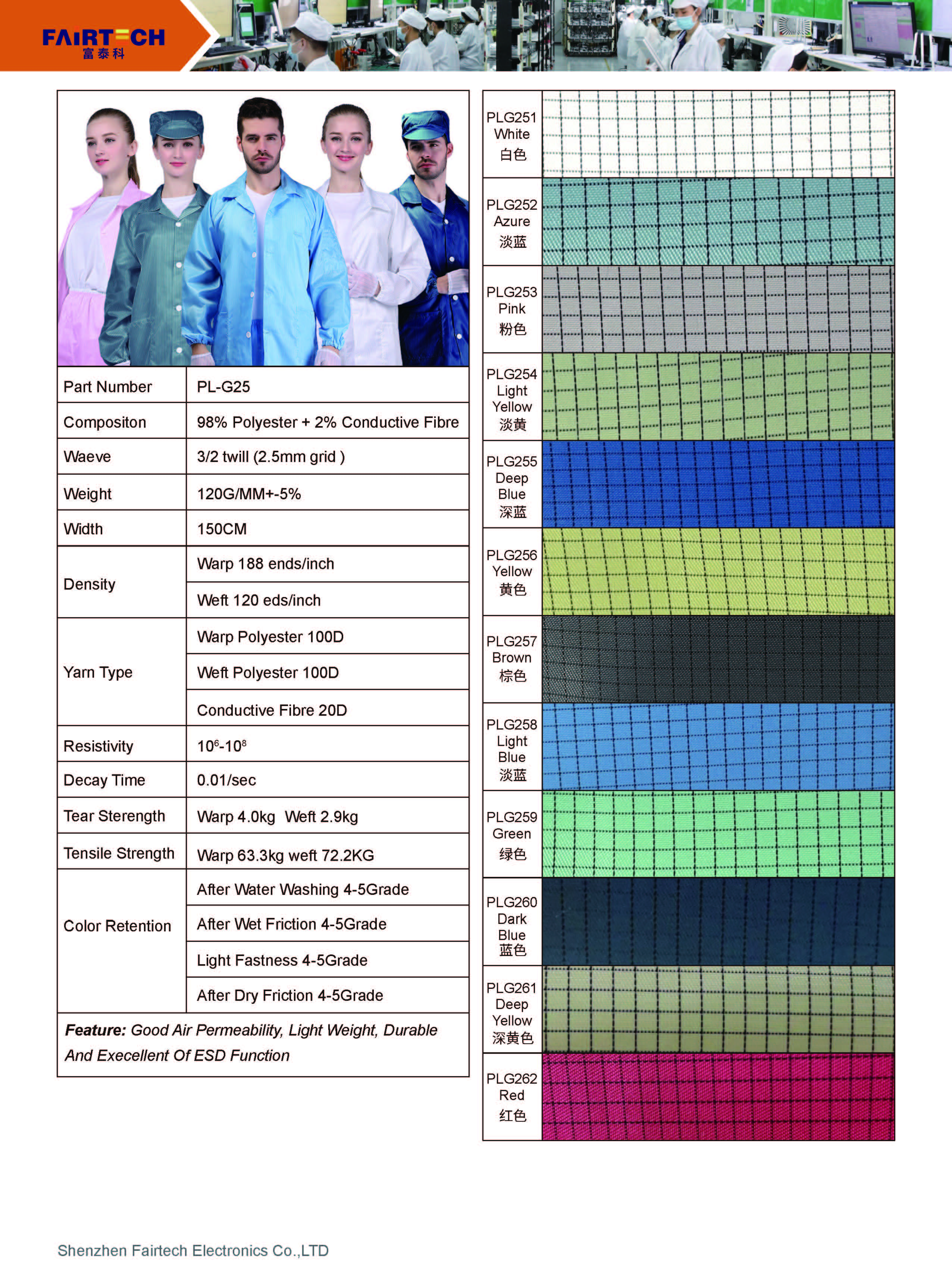

Conductive Silk, also known as ESD fabric, is made of special polyester filament and high quality conductive yarns, and is suitable for sewing various functional garments such as coveralls, suits, jackets, caps and boots. With excellent static, chemical and abrasion resistance, it is designed for Class 1000 cleanrooms and above, and can be widely used in electronics, medical, biology, optics and spaceflight industries, meeting the ESD standards with system resistance ranging from 10e6-10e8Ω.

Conductive Fabric is prepared by blending metal oxide and carbon black in composite spinning. It has the ability to separate or blend conductive fiber fabric during spinning to prevent the accumulation of static electricity of clothing. In addition, the density average of fabric charge surface should remain below 7.0μc/m2 even after washing 100 times, and the electricity etymology of each cloth should be lower than 0.6μ c/pc, while A-grade and B-grade should reach 33.0 h and 16.5 h washable.

| Parameter | Value |

|---|---|

| Width | 58/60 |

| Sample | Available |

| Function | Antistatic |

| Yarn Count | 100d*100d, 100d*100d |

| Static Decay | 0.1s |

| Use | Jacket, Shirt, Bag, Blanket, Cap, Curtain, Dress, Garment, Industry, Shoes, Suit |

| Surface Resistance | 10^6-10^9Ω |

| Style | Other, TWILL, Antistatic |

| Permeability to Water | 55.00 To 60.00g/hr |

| Density | 188*120 |

Antistatic fabrics find applications in many industries where static electricity control is critical. In particular, they can be used in electronics and semiconductor manufacturing, automotive industry, pharmaceutical and healthcare sectors, and for handling explosive or flammable materials.

For electronics and semiconductor manufacturing, antistatic fabrics can be made into garments, gloves, and even cleanroom clothing for personnel. This is done to protect sensitive electronic components from electrostatic discharge.

In the automotive industry, antistatic fabrics are employed in the production of both seating materials and protective clothing. This is so static build-upp and potential hazards can be minimized during the assembly of the vehicle.

Antistatic fabrics are also utilized in pharmaceutical and healthcare sectors. This is because they are often used in cleanrooms and sterile environments. This is to prevent static electricity and protect any sensitive equipment or products.

Additionally, for explosive or flammable substance handling, workers often wear clothing and use equipment made with antistatic fabrics. This is to prevent any static discharge, which may cause ignition.

Finally, antistatic fabrics can maintain their conductivity and antistatic properties for a longer duration of usage. However, it is important to follow the manufacturer's instructions for proper care and maintenance. Proper washing, drying, and handling are crucial for retainment of the fabric's conductive properties.

Brand Name: Fairtech

Model Number: FR2101

Place of Origin: China

Certification: CE, ISO

Minimum Order Quantity: 100 Meters

Price: USD1.1/Meter

Packaging Details: 100-130meter/roll

Delivery Time: 3-5days

Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability: 10000000meter per Week

Color: White, Blue, Pink, Yellow, Green And Etc

Type: 5mm Grid/Strip Fabric Or 4mm Grid/Strip Fabric

Function: Anti-Static

Use: Jacket, Shirt, Bag, Blanket, Cap, Curtain, Dress, Garment,

Industry, Shoes, Suit

Thickness: Lightweight

Fairtech's Anti-Static ESD Fabrics are designed to provide excellent protection against electrostatic discharge. Our fabrics are perfect for a variety of applications, including jackets, shirts, bags, blankets, caps, curtains, dresses, garments, industry, shoes, and suits. Our fabrics feature a 5mm or 4mm grid/strip design and come in a variety of colors, such as white, blue, pink, yellow, and green. Our fabrics are lightweight and certified CE and ISO.

We offer competitive pricing on our quality ESD fabrics with a minimum order quantity of 100 meters. We offer a variety of payment options, including L/C, D/A, D/P, T/T, Western Union, and MoneyGram. Our delivery time is 3-5days and our fabrics are packaged in 100-130meter/rolls. We have a large supply capacity of 10,000,000 meters per week.

If you're in need of high-quality antistatic fabric, ESD antistatic fabric, ESD grid fabric, or ESD strip fabric, look no further than Fairtech. Shop our selection today and enjoy competitive prices and fast delivery.