Hebei Tengtian Welded Pipe Equipment Manufacturing Co.,Ltd. |

|

Verified Suppliers

|

|

Hole Design Electric Welded Steel Pipe Extrusion Auto Produce Tube Mill

I. Introduction

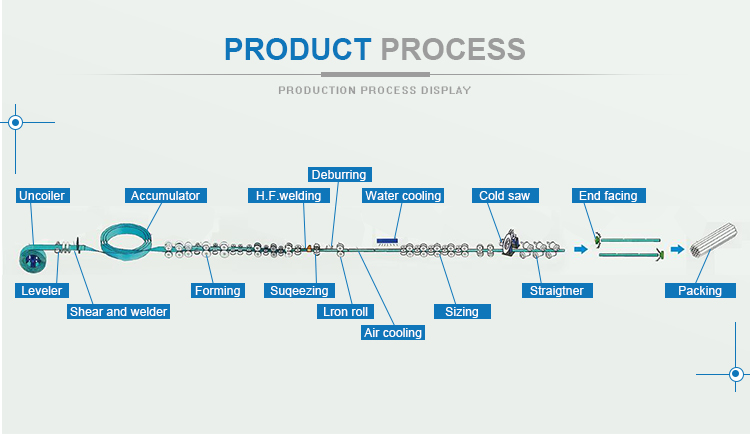

The high-frequency straight seam welded pipe production line feeds a certain specification of steel strip into the unit, rolls the steel strip into a tube billet through rollers, and then uses the proximity effect and skin effect of high frequency to instantly heat the edge of the strip to the welding temperature. The welding is completed under the force of the extrusion roller, and then it is cooled by water, sizing and straightening to become the steel pipe of the required specification. The operation and maintenance are convenient and simple. The unit has high processing quality and assembly accuracy, and can produce electric welded steel pipes with relatively high precision by adopting a reasonable roll pass.

II. Product applicable industry

III. Equipment composition

| 1. Loading car | 2. Uncoiler |

| 3. Straightener unit | 4. Flattener unit |

| 5. Automatic Shear & Welder | 6. Accumulator |

| 7. Forming & Sizing | 8. Cold saw / Milling saw / Flying saw |

| 9. Transit roller + Unloading Rack | 10. Automatic palletizing machine |

| 11. Roller | 12. High frequency welder |

IV. Product parameter specifications

| Model | Side length Range | Thickness | Production speed (m/min) | Motor Power(KW) | Mechanical area |

| (m³) | |||||

| HG20 | 6 x 6 ~ 16 x 16 mm | 0.3 -1 mm | 30 - 120 | 55 | 7 × 50 |

| HG32 | 9 x 9 ~ 25 x 25 mm | 0.3 - 2.0 mm | 30 - 120 | 75 | 7 × 50 |

| HG50 | 12 x 12 ~ 40 x 40 mm | 0.8 - 2.5 mm | 30 - 110 | 110 | 7 × 60 |

| HG60 | 15 x 15 ~ 47 x 47 mm | 0.8 - 3 mm | 30 - 100 | 132 | 7 × 65 |

| HG76 | 9 x 9 ~ 60 x 60 mm | 1 - 3 mm | 30 - 100 | 320 | 8 × 80 |

| HG89 | 25 x 25 ~ 70 x 70 mm | 1 - 4 mm | 30 - 80 | 350 | 8 × 80 |

| HG114 | 35 x 35 ~ 89 x 89 mm | 1.5 - 5.0 mm | 30 - 60 | 400 | 10 × 100 |

| HG165 | 47 x 47 ~ 129 x 129 mm | 3 - 7 mm | 30 - 50 | 600 | 10 × 110 |

| HG219 | 89 x 89 ~ 172 x 172 mm | 4 - 8 mm | 20 - 40 | 800 | 12 × 150 |

| HG273 | 89 x 89 ~ 214 x 214 mm | 4 - 10 mm | 15 - 30 | 1000 | 18 × 160 |

| HG325 | 129 x 129 ~ 255 x 255 mm | 4 - 12 mm | 10 - 30 | 1200 | 18 ×180 |

| HG426 | 129 x 129 ~ 335 x 335 mm | 4 - 16 mm | 8 - 25 | 1400 | 18 × 180 |

| HG508 | 172 x 172 ~ 400 x 400 mm | 4 - 20 mm | 8 - 20 | 2000 | 21 × 180 |

| Recent business technology expansion, adding available projects | |||||

| HG600 | Production line for Square welded pipes, max side length of pipe is 600 x 600mm. | ||||

| HG765 | Production line for Round welded pipes, max diameter of pipe is 765mm. | ||||

V. Factory appearance