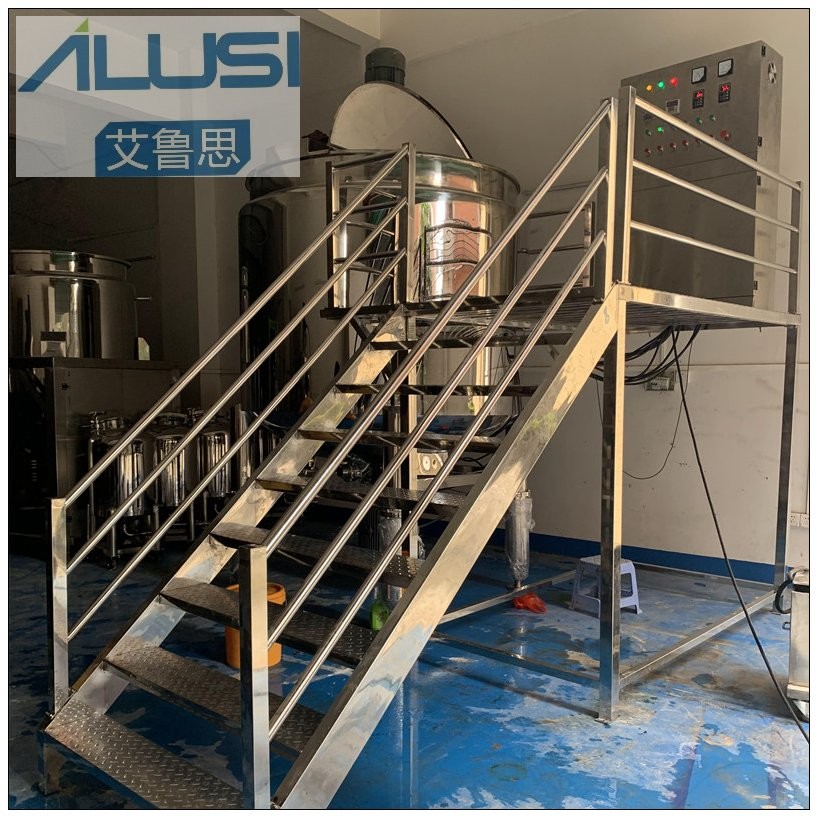

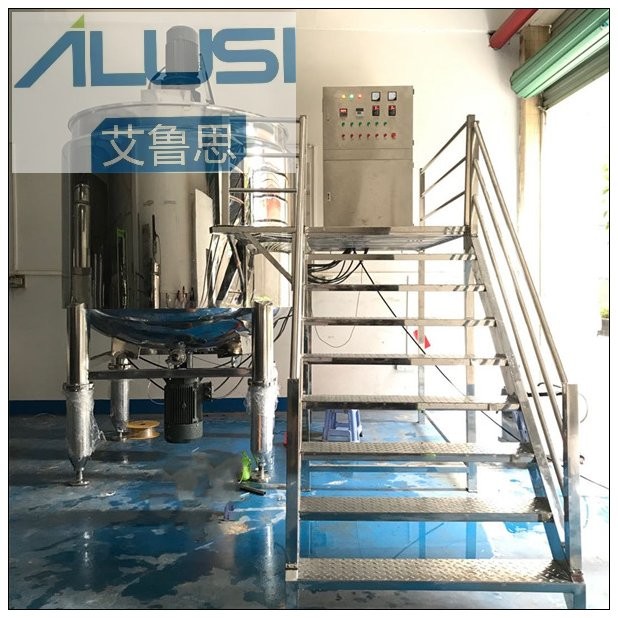

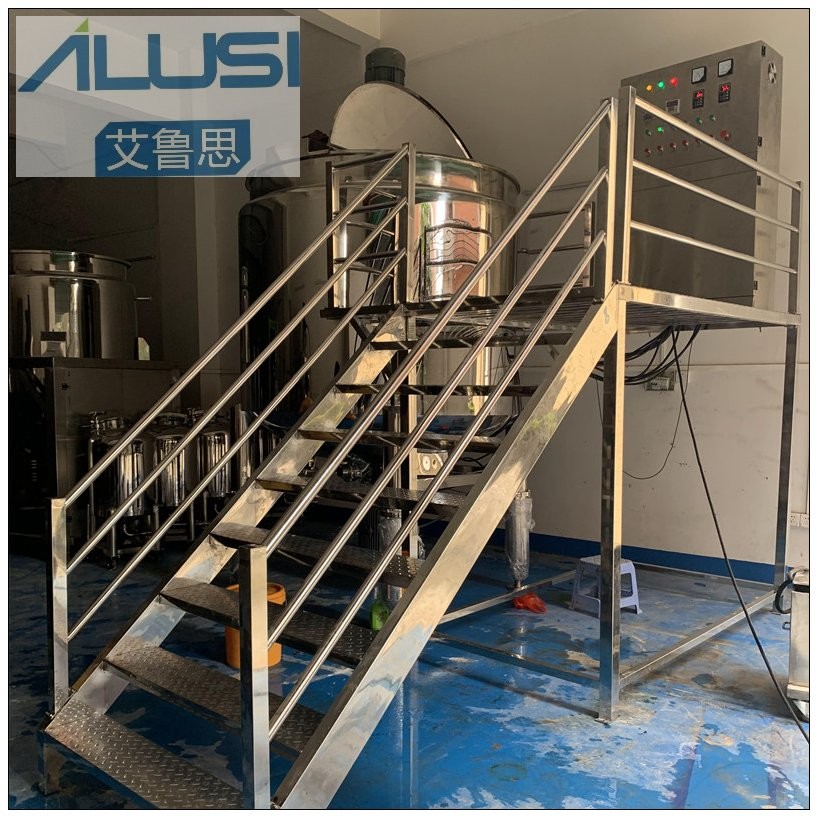

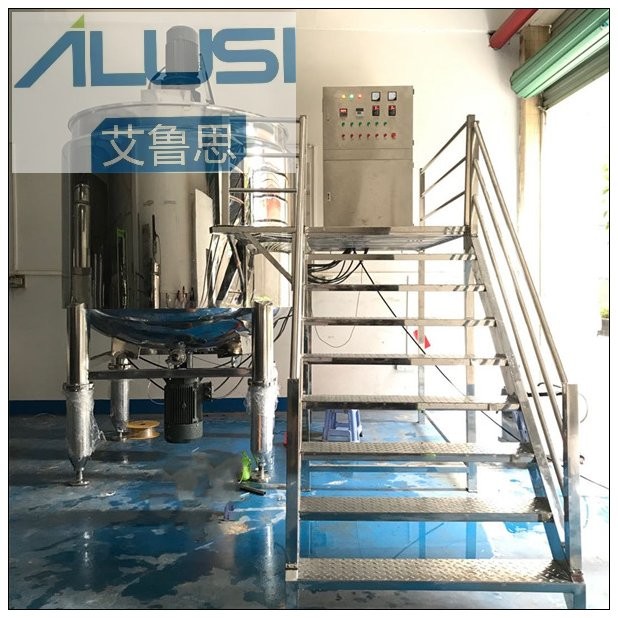

Main Features:

1) Full of SUS304, contact materials parts SUS316L, GMP standard..

2) Adopting advanced world famous brand components in pneumatic

parts ,electric parts and operation parts.

3) Double jackets and insulation provide electric heating or steam

heating..

4) High effection mixer and homogenizer emulsion products 2um.

5) Apply to cosmetics, shampoo, liquid soap, detergent, dish

washing etc products.

Product Details:

Item | Heater(KW) | Mixer(KW) | Mixer Speed(RPM) | Homogenizer(KW) | Homogenizer Speed(RPM) |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

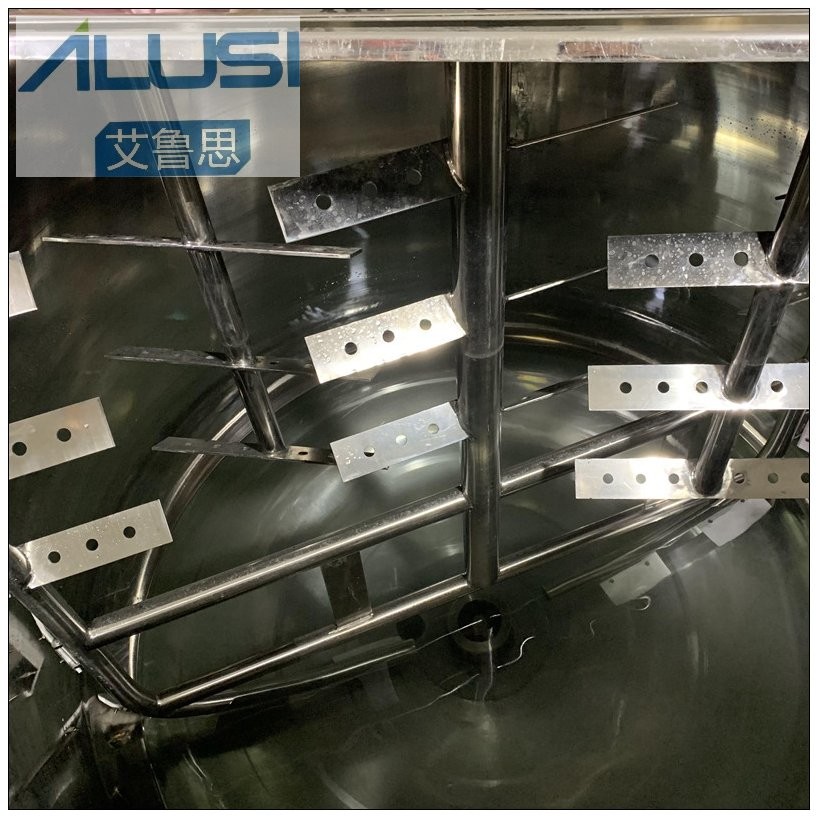

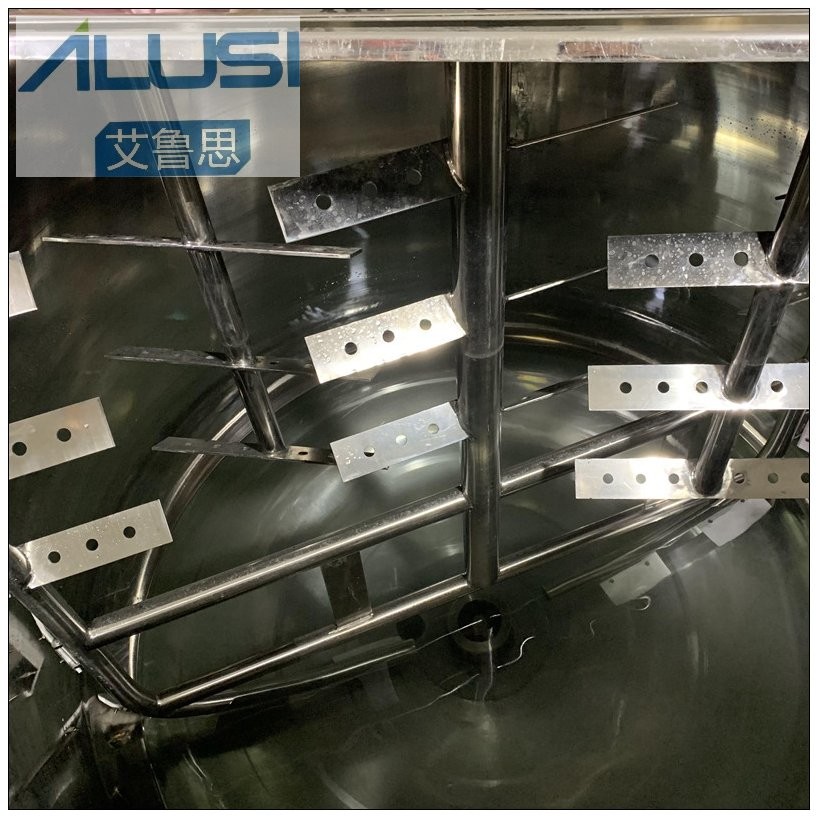

Mixing part

Mixing part: Frame oar scraping blender with 1 fixed oar

Material: SUS316L

Siemens motor + reducer provide strong and stable power for mixer, Panasonic brand frequency inverter, PTFE material scrape blade, Flange shaft

coupling.

Bidirectional stirrer paddle: Stir up and down, mixing more evenly

Wall Scraper: Scraping off the materials that stick on pot wall, to make all materials mixing more evenly

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.