Guangzhou Ailusi Machinery Co., Ltd. |

|

Verified Suppliers

|

|

Our 50L Stainless Steel Mixing Tank is an ideal solution for liquid chemical and food blending processes. Crafted from durable stainless steel, it ensures exceptional hygiene standards and long-lasting performance. The tank features a heating jacket, allowing precise temperature control during mixing, blending, and emulsification operations. With a 50-liter capacity, it is suitable for small to medium-scale production requirements. The mixer tank incorporates a reliable and efficient mixing mechanism, ensuring thorough homogenization of ingredients and consistent product quality. Its compact design and user-friendly controls make it easy to operate and clean. Whether you're involved in chemical production or food processing, this versatile tank guarantees efficient and reliable performance, making it an essential asset for your production facility. Enhance your manufacturing processes with this high-quality and multifunctional mixing tank.

FEATURES

Premium Material: Constructed from high-quality stainless steel, ensuring durability, resistance to corrosion, and compliance with hygiene standards.

Heating Jacket: The tank is equipped with a heating jacket that allows precise and controlled heating during the blending process, enabling temperature-sensitive products to be handled with ease.

Versatile Capacity: With a 50-liter capacity, it is suitable for small to medium-scale production needs, making it ideal for laboratories, pilot plants, and small manufacturing setups.

Efficient Mixing Mechanism: The tank incorporates an efficient mixing system, ensuring thorough homogenization and blending of liquid chemicals and food ingredients.

User-friendly Controls: Equipped with easy-to-use controls, making operation and adjustments straightforward for operators.

Easy Cleaning: Designed with hygiene in mind, the tank is easy to clean and sanitize, minimizing downtime between different batches.

| Model | AHM-50 | Working capacity | 50L |

| Heating method | Steam/electric | Working capacity | Frame wall scraper mixing |

| Mixing motor power | 3KW | Mixing frequency | 3KW |

| Mixing Speed | 0-65rpm | Homogenizer frequency | 5.5KW |

| Bottom Homogenizer power | 5.5KW | Homogenizer type | Internal and external circulation(option) |

| Control method | Button control | Frequency converter | Delta/Panasonic/Mitsubishi |

| Electrical components | Schneider/Delixi | Tank materials | Inner layer 4mm/SUS316 Middle layer 4mm/SUS304 Outer layer 3mm/SUS304 |

PRODUCT CONFIGURATION

|  |  |

| Siemens BEIDE Motor | Reducer | Delta Frequency inverter |

|  |  |

| Stator and rotor | rotor | Materials SUS304&316L(TISCO) |

|  |  |

| Burgmann Mechanical seal | NSK Bearing | Omron temperature controller |

|  |  |

| Indicator light, Schneider | Button , Schneider | Current Transformer,Delixi |

|  |  |

| Time Relay | Breaker | AC contactor |

CERTIFICATION

MATERIALS SOURCE

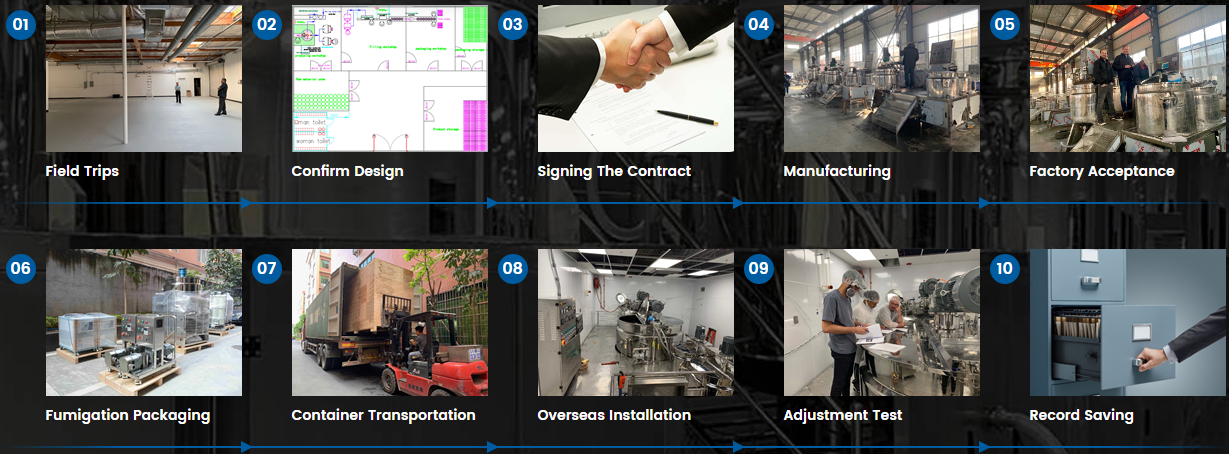

PROJECT

Our Service

After-sales Service: Online support,Video technical support,Free spare parts

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.