Guangzhou Ailusi Machinery Co., Ltd. |

|

Verified Suppliers

|

|

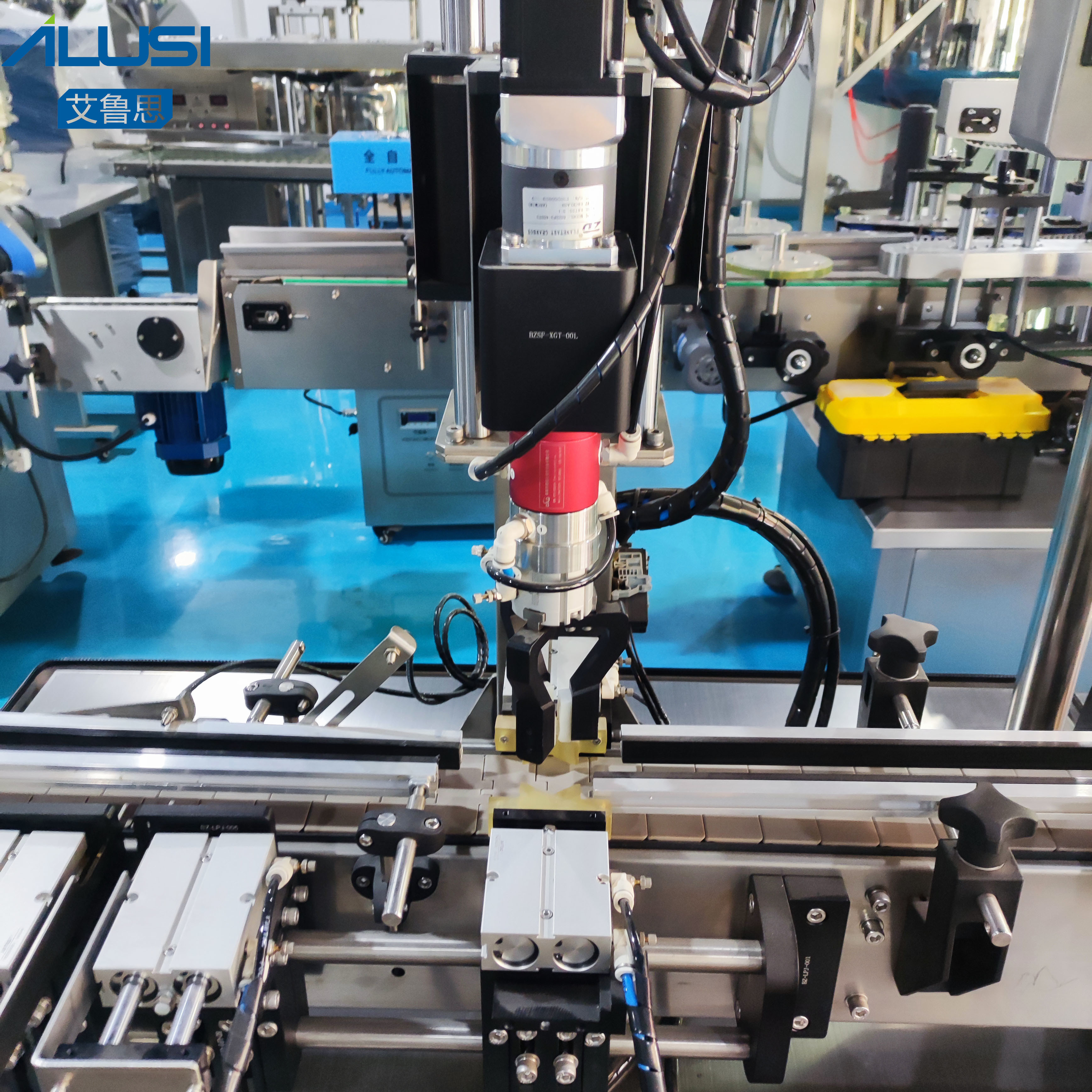

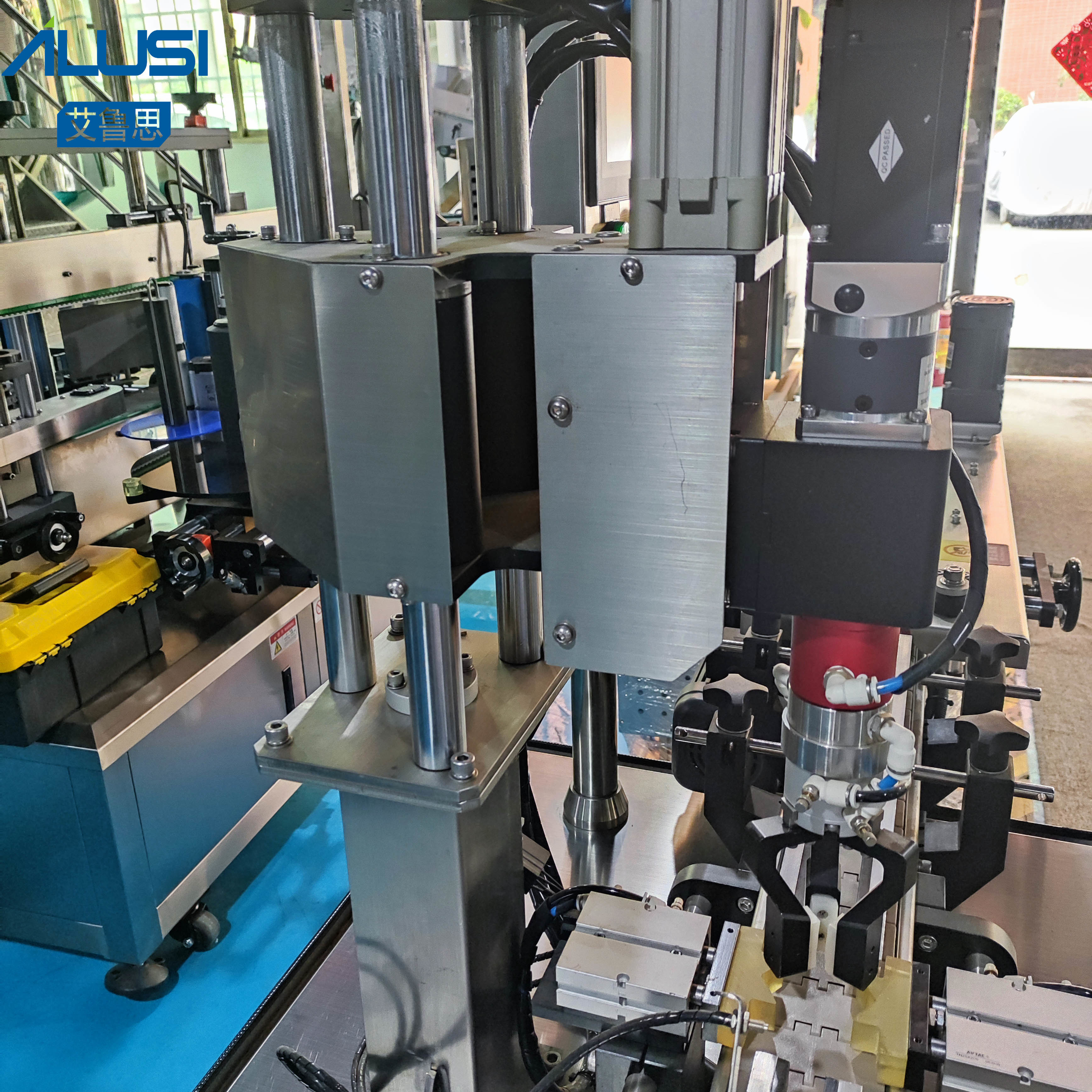

The Automatic Screw Capping Machine is a cutting-edge solution designed for efficiently sealing glass bottles with metal caps. It is specifically developed to meet the demands of industries such as pharmaceuticals, beverages, and cosmetics. This advanced machine automates the capping process, ensuring precise and consistent results while minimizing manual labor and increasing productivity.

Equipped with advanced technology, the Automatic Screw Capping Machine features a user-friendly interface and adjustable settings to accommodate various bottle sizes and cap types. It utilizes a reliable screwing mechanism that securely fastens the metal caps onto glass bottles with accuracy and stability. With its high-speed operation and robust construction, this machine offers reliable performance, reducing downtime and enhancing overall production efficiency.

The Automatic Screw Capping Machine is an indispensable tool for businesses seeking a reliable and efficient solution for sealing glass bottles with metal caps, enabling them to streamline their operations and deliver products with optimal quality and consistency.

Item NO.:APM

Lead Time:15-25 Days

Product Orgin:China

Shipping Port:Guangzhou Port

Payment:EXW, C&F, CIF and etc.

price range:2-10/5500$

MOQ:1

Product Detail

Main Features:

The main feature of the Screw Capping Machine is its fully automatic rotary operation, which offers several benefits:

High Efficiency: The machine operates at high speeds, ensuring fast and efficient capping of glass bottles with metal caps. Its rotary design enables continuous operation, maximizing productivity and minimizing production line downtime.

Versatility: The capper is compatible with a wide range of glass bottle sizes and metal cap types, making it suitable for various industries and packaging requirements. It offers flexibility in handling different bottle and cap specifications.

Precision and Consistency: The machine is engineered to provide precise and consistent capping results. It ensures that each cap is tightly sealed onto the bottle, preventing leakage or contamination.

User-Friendly Interface: The Screw Capping Machine features a user-friendly interface that simplifies setup, adjustment, and control. Operators can easily configure the capping parameters and monitor the machine's performance.

Durability and Reliability: With its robust construction and high-quality components, the capper is built to withstand rigorous production environments. It offers long-term durability and reliable performance, reducing maintenance requirements.

Components:

PLC control system

Cap sorting part and cap loading part machine frame

2 meter straight conveyor line(can do customized)

Can be used with filling machine and labeling machine

Conveyor, capping speed and capping time can be easily debugged

This machine is made of stainless steel and is GMP-compliant and durable

Factory:

Our Servers:

After-sales Service: Online support,Video technical support,Free spare parts

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.