Guangzhou Ailusi Machinery Co., Ltd. |

|

Verified Suppliers

|

|

The industrial SS stainless steel 3000L cosmetic homogenizer mixer tank is a state-of-the-art equipment specifically designed for the efficient mixing and homogenization of creams and liquids in the cosmetic industry. This high-capacity tank is built with premium quality stainless steel, ensuring durability, hygiene, and resistance to corrosion.

With a generous capacity of 3000 liters, this mixer tank can handle large batches of cosmetic formulations with ease. It is equipped with a powerful homogenizer that utilizes high-speed rotation and shear forces to achieve thorough blending and emulsification. The homogenizer is adjustable, allowing you to control the intensity and duration of mixing to achieve the desired consistency and texture.

The tank features a sturdy design with airtight seals, preventing any leakage or contamination during the mixing process. It is equipped with a variety of mixing mechanisms, such as agitators and paddles, to ensure uniform distribution of ingredients and prevent settling or clumping. The mixing speed and time can be adjusted to accommodate different viscosities and formulations.

Additionally, the tank is equipped with temperature control capabilities, allowing you to heat or cool the contents as required for specific formulations. It also includes a monitoring system with gauges and sensors to ensure precise control and monitoring of temperature, pressure, and other important parameters.

The industrial SS stainless steel 3000L cosmetic homogenizer mixer tank is an essential tool for cosmetic manufacturers, providing efficient and reliable mixing, homogenization, and emulsification of creams and liquids. Its robust construction, advanced features, and large capacity make it ideal for high-volume production while maintaining product quality and consistency.

FEATURES

1. The Omnidirectional wall scraping and mixing adopts a frequency converter to adjust the speed. At low temperatures and high viscosity, it can reduce the formation of bubbles.

| Model | AHM-3000 | Working capacity | 3000L |

| Heating method | Steam/electric | Working capacity | Frame wall scraper mixing |

| Mixing motor power | 3KW | Mixing frequency | 3KW |

| Mixing Speed | 0-65rpm | Homogenizer frequency | 5.5KW |

| Bottom Homogenizer power | 5.5KW | Homogenizer type | Internal and external circulation(option) |

| Control method | Button control | Frequency converter | Delta/Panasonic/Mitsubishi |

| Electrical components | Schneider/Delixi | Tank materials | Inner layer 10mm/SUS316 Middle layer 10mm/SUS304 Outer layer 8mm/SUS304 |

PRODUCT CONFIGURATION

|  |  |

| Siemens BEIDE Motor | Reducer | Delta Frequency inverter |

|  |  |

| Stator and rotor | rotor | Materials SUS304&316L(TISCO) |

|  |  |

| Burgmann Mechanical seal | NSK Bearing | Omron temperature controller |

|  |  |

| Indicator light, Schneider | Button , Schneider | Current Transformer,Delixi |

|  |  |

| Time Relay | Breaker | AC contactor |

Application

Shampoo Production: The mixing machine is specifically designed for shampoo production. It allows for efficient blending of various shampoo ingredients, including surfactants, conditioning agents, fragrances, and colorants. The bottom homogenizer ensures a homogeneous mixture, resulting in high-quality shampoos with consistent texture and performance.

Body Soap Manufacturing: The machine is equally suitable for body soap production. It enables thorough mixing of soap base, moisturizers, exfoliants, and other additives, ensuring a uniform distribution throughout the soap formulation. The bottom homogenizer helps in achieving a smooth and luxurious lather, enhancing the overall quality of the body soap.

Cosmetics and Personal Care Products: Beyond shampoos and body soaps, the mixing machine can be employed for producing a wide range of cosmetic and personal care products. It can be used to blend creams, lotions, gels, and other formulations. The bottom homogenizer feature is particularly advantageous for achieving the desired texture and emulsion stability in these products.

Beauty and Skincare Products: The machine is suitable for the production of various beauty and skincare products. It can be utilized to mix ingredients for facial cleansers, body washes, shower gels, and other cleansing products. The precise controls and programmable settings allow manufacturers to achieve specific formulations, textures, and fragrance profiles to meet consumer preferences.

Hair Care Products: The mixing machine is ideal for hair care product manufacturing. It can be used to blend ingredients for conditioners, hair masks, serums, and styling products. The efficient mixing capabilities ensure that the active ingredients are evenly distributed, enhancing the efficacy of the hair care formulations.

Industrial and Institutional Cleaning Products: The machine can also be applied in the production of industrial and institutional cleaning products. It enables thorough mixing of ingredients for detergents, degreasers, and sanitizers, ensuring a consistent and effective cleaning performance.

MATERIALS SOURCE

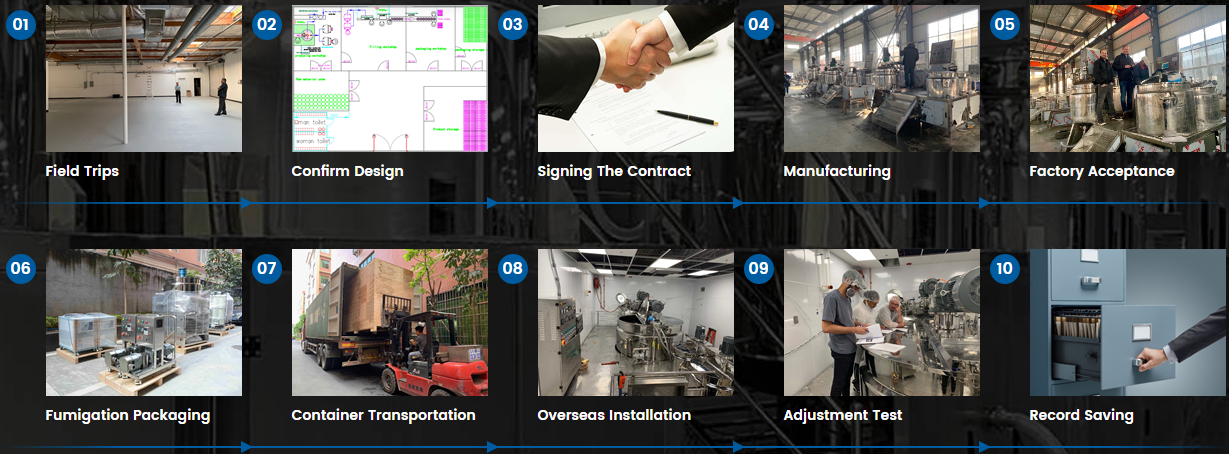

PROJECT

Our Service

After-sales Service: Online support,Video technical support,Free spare parts

FAQ

Q1: Are you a factory or trading company?

A1: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2: How does your factory do regarding quality control?

A2: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3: What’s the guarantee and the after service if we purchase from you?

A3: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4: Are your machines difficult to operate? How do you teach us to use the machine?

A4: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5: Can you make the machine according to customers' request?

A5: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.