Guangzhou Lianhe Machinery Co., Ltd. |

|

Automatic Bottle Capping Machine Plastic Bottle Screw Capping Machine

Product description:

This automatic screw capping machine is one of the main equipment of automatic filling production line, capping machine is a kind of sealing machine, plastic bottle cap sealing machine is widely used in glass bottle or PET bottles of screw cap sealing, because the screw cap with sealing fast, easy to open and re-open Screw cap,etc., so some non-gas liquid material, such as beverages, alcohol, spices and other similar packaging of the bottle with a large number of screw cap sealing.

It applies to screwing for vacuum sealing of glass bottle products such as seasoning, pickles, fermented bean curd and jam.

The product is mainly appropriate to seal plastic bottles and glass bottles with advanced product design, reasonable structure and easy and simple operation. It is necessary and ideal packaging equipment of food and other industries.

The product conforms to regulations of national standards, departmental standards and enterprise standards and can be allowed to leave the factory after qualification of strict inspection and test.

Product application:

This machine is used for automatic capping for plastic bottles and glass bottles in cosmetic, food, beverage, chemical industry and medicine industry. It can be applied to a variety of bottle types with high production efficiency. Suitable for bottles or jars, pump head, flip-top head, jars cap, trigger cap, etc.

Product parameters:

| Technical Parameters | |

| Capping speed | 30-50 bottles per minute |

| Applicable cap | Flip-top type, pump-head type, trigger type, dropper type, and all other screw type cap |

| Capping form | 4 wheels clamp screw the cap |

| Material | Stainless steel 304 |

| Capping motor | 220W motor |

| Air Pressure | 0.6-0.8 Mpa |

| Cap feeding | Manually or automatically selectable |

| Voltage | Single phase voltage, customized according to your request |

Product advantages:

1. Rotary Knob: different diameter bottle clamping and bottle height can be adjusted by rotating knob, suitable bottle height is 20-110mm, also can be customized according to your actual bottle samples. Stainless steel 304 machine body for higher quality standard.

2. Bottle height rotary knob: capping head can be adjusted according to different height of bottle by this rotating knob, suitable bottle height is 30-300mm (can be customized according to your actual bottle size.

3. Bottle sensor (SICK or Panasonic), high quality sensor sense the bottle automatically, it helps to improve working speed and save a lot of labor.

4. Operation panel: SIEMENS PLC touch screen control system, for stable performance and high class appearance.

Product Features:

1.The working height can be adjusted by the rotary knob, suitable bottle height is 60-270mm

2. Designed for various shapes of bottle caps,like smoke oil bottles, spray bottles, beverage bottle caps. It will press the bottle caps and tight it automatically Improve working efficiency greatly.

3. This machine is with electric eyes, can prevent from missing bottles, reduce the working error,the sensitivity of the electric eye can be adjusted by the black machine part during working.

4. With conveyor, this machine can transfer bottles automatically, save labor, reduce the production process and improve the working accuracy.

5. Equipped with powerful motor, the main motors and the conveyor motor are separately, ensure that the machine can work stably and safely.

6. The barometer can be used to watch the air pressure in real time.This machine should work with air compressor ,customers need to buy it separately.If you need it, please contact us.

Product details:

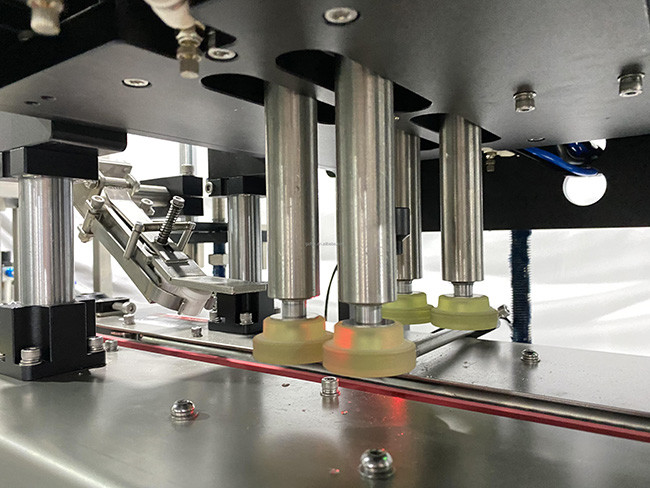

1. 4 wheels screwing capping head, its capping height and capping width is adjustable to suit your different caps diameter.

2. SIEMENS PLC touch screen control, high class appearance, stable performance.

3. Automatic cap feeding system can be added if you need.

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte

E