|

|

[China]

Trade Verify

Address: Room 63, 7/F, Woon Lee Commercial Building, 7-9 Austin Ave, Tsim Sha Tsui, Kowloon, Hong Kong

Contact name:Doris

Surplus Industrial Technology Limited |

|

Verified Suppliers

|

|

GKD series high power DC power supply

Application

Metal plating, plastic plating, electrolytic copper foil, chrome

plating,aluminum profile oxidation, Rare earth smelting, tinplate

galvanizing,

water treatment and other industries;

Features:

1. Small size, light weight, electricity-saving, high accuracy;

2. Very low ripple coefficient, high control accuracy and better

electroplated

coating uniformity;

3. Constant current and voltage operation mode, free switching

4. Electronic switcher for positive and negative switching, with

fast response

time, less than 100ms;

5. Equipped with RS232 & RS485 interface;(Optional)

6. 4-20mA, 0-5V, 0-10V analog(optional)

7. PROFIBUS, DeviceNet, modbus(optional)

8. Built in ampere hour meter function;

9. With over temperature, over voltage, under voltage, overload,

short circuit

protection function;

10. Sealing structure design, with the use of acid and alkali proof

waterproof

function- three anti paint, make the product more durable

Technical parameters:

| Input voltage | 3xAC220V±10%,50/60Hz 3xAC380V±10%,50/60Hz Other voltages can be customized as required |

| Power factor | ≥0.95 |

| Output Voltage | 0-800vdc, customized; |

| Cooling mode | Air cooled or water cooled |

| Output Current | 0 - no upper limit(manual 20000A maximum) |

| Insulation resistance | Input-output / input-shell / output-shell: ≥ 5m Ω |

| Rated efficiency | 90% type |

| Load capacity | No fault during 72 hours of full load operation |

| RoHS compliance | conformity with EU Directive 2011/65/EU |

| Safety standards | conformity with EU 2006/95/EC,2004/108/EC |

| Degree of Protection | Air cooling IP33, water cooling IP43 or 66 |

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of the product you need.It is much better if you could offer the usage information about products.

We will comfirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes,we can produce the products according to your demand and drawing.

3. What is your production lead-time for order?

Generally it takes 15-25 days for production.

4. What are your payment terms?

In generally,we quote EXW price+shipping cost,payment 50% deposit by T/T in advance,50% balance paid before shipment.

If the account is small ,so you can pay via Western Union.

Products Show

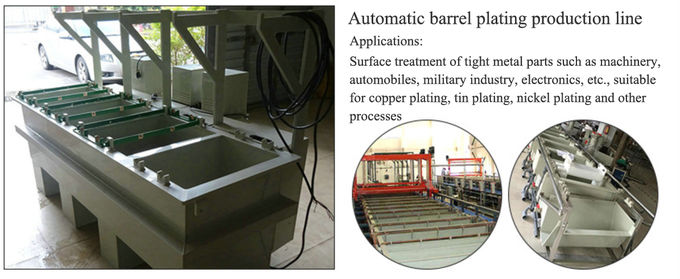

1. Automatic Barrel plating production line

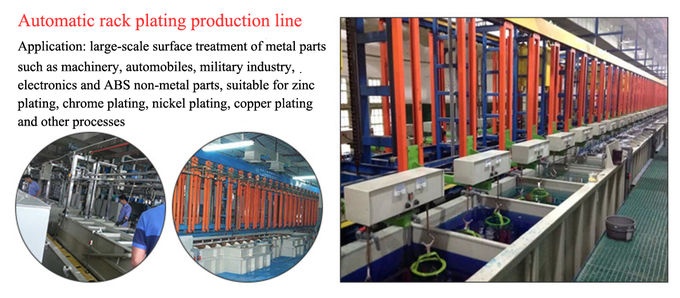

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

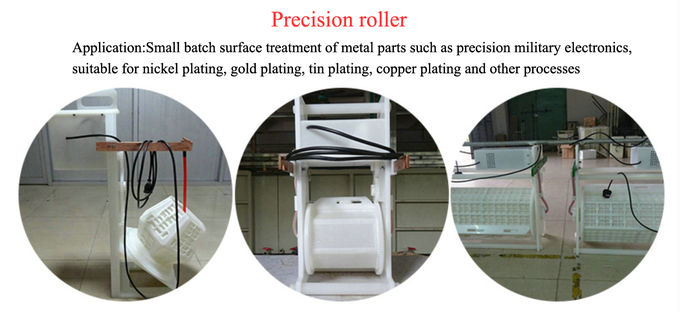

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

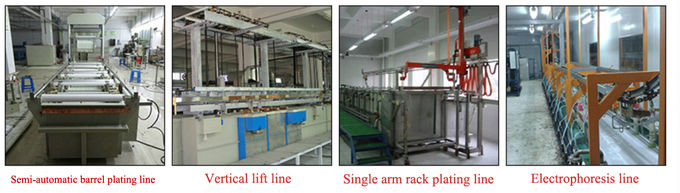

Project display

|

|

|

|

Packing & Shipping

In our company,various packing methods are adopted according to different product features,such as carton boxes,wooden case etc.For electroplating plant equipment ,we can discuss it together and choose the most suitable one.

As for shipment,different ways have their own advantage and disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, much more expensive

By Express: more flexiable, door to door, a little bit expensive