Surplus Industrial Technology Limited |

|

Verified Suppliers

|

|

| materials | pp |

| Product name | Semi-automatic Manual Type Barrels Plating Drum PP Barrel Plating Equipment |

| application | Electroplating /barrel plating /barrel plating macine. |

| Ability | heat-resistant,corrosion resistance |

| Conductive | Dangler with copper cable ductive |

| Applicable products | different kinds of products |

| Applicable plating | Zinc ,chrome ,nickel ,copper,gold ect. |

Barrel plating is a form of electroplating used to plate large numbers of smaller metal objects at one time. It consists of a non-conductive barrel-shaped cage in which objects are placed before passing through a chemical bath where they are then electroplated. An important aspect of the barrel plating process is that the individual components establish bipolar contact with each other to achieve high plating efficiency. However, due to the high amount of surface contact between parts, barrel plating is generally not recommended when precise design or decorative finishes are required.

Applies for electronic products(such as chip resistor,diode

andsimilar shape products).

Suitable for copper/nickel/tin or other compound plating.

Equipped with automatic crane and manual-automatic changeover

switch,the crane could set with liquid collect plate and hanging

rotating de-watering device.

The plating process could be set with customized program according

to requirement,multiple programs could be set and save at the same

time,with human-machine interface.

Industrial control computer could be provided according to

customer's need,which can collect and record the real-time plating

parameters for customer to track the plating quality.

Packing & Shipping

In our company,various packing methods are adopted according to

different product features,such as carton boxes,wooden case etc.For

electroplating plant equipment ,we can discuss it together and

choose the most suitable one.

As for shipment,different ways have their own advantage and

disadvantage:

By sea: the cheapest,suitable for large amounts,but take more time

By Air: faster, more convenient, expensive

By Express: more flexiable, door to door, expensive

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and mark your purchase quantity of the product you need.It is much better if you could offer the usage information about products.

We will comfirm the most suitable material and quote our best price to you in 24 hours.

2. Can you accept OEM & ODM?

Yes,we can produce the products according to your demand and drawing.

3. What is your production lead-time for order?

Generally it takes 15-25 days for production.

4. What are your payment terms?

In generally,we quote EXW price+shipping cost,payment 50% deposit by T/T in advance,50% balance paid before shipment.

If the account is small ,so you can pay via Western Union.

Company Advantage:

1. Professional,Powerful, Precision Design

2. Build a quality levee to meet the challenges of the century

3. Focus on research and development for 18 years, master core

technology

4. Quality and Thoughtful Service

Related Product Show

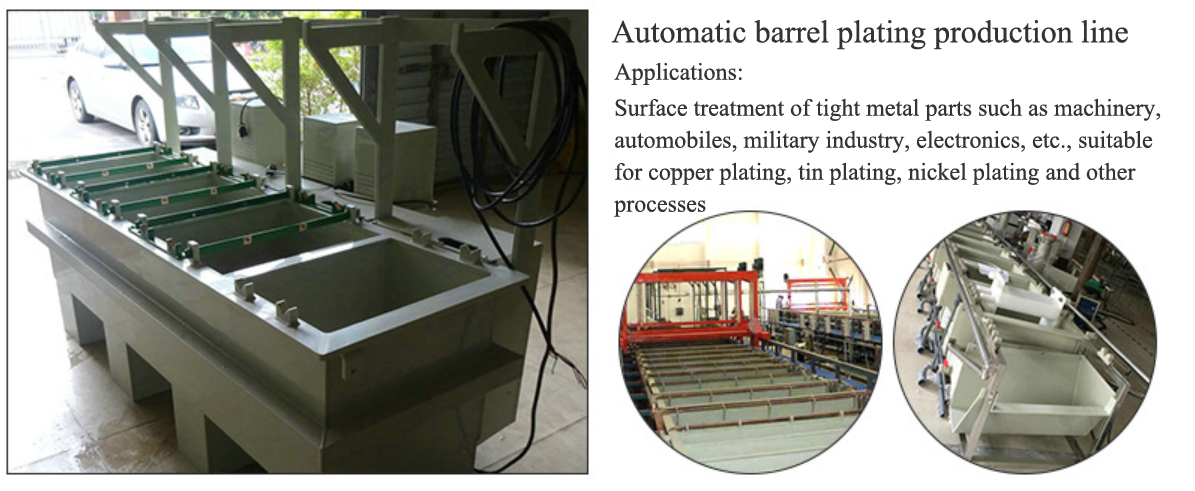

1. Automatic Barrel plating production line

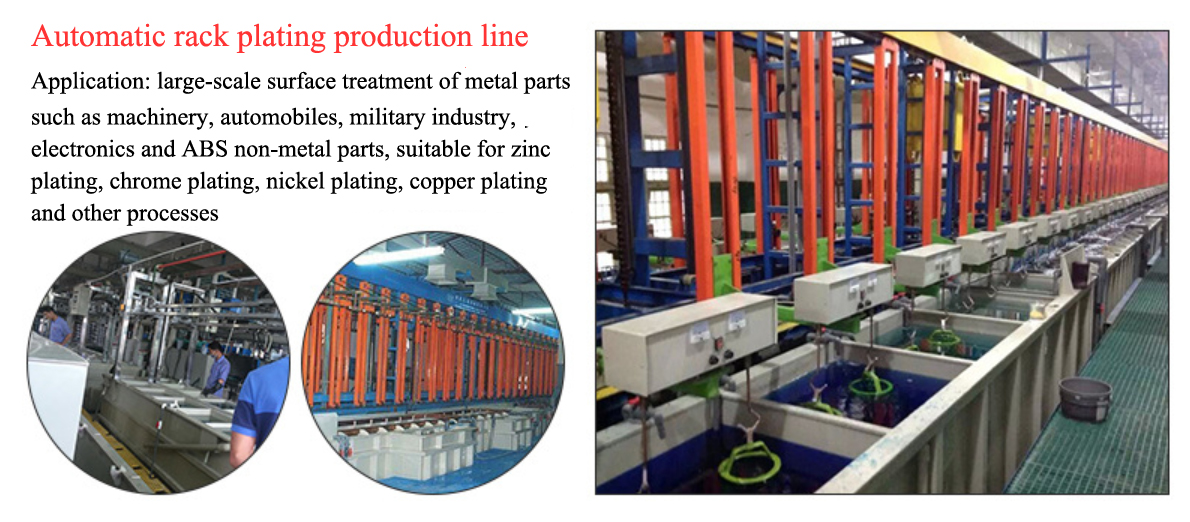

2. Automatic rack plating production line

Application: large-scale surface treatment of metal parts such as machinery, automobiles, military industry,electronics and ABS

non-metal parts, suitable for zinc plating, chrome plating, nickel plating, copper plating and other processes.

3. Precision roller

Application range:Small batch surface treatment of metal parts such as precision military electronics, suitable for nickel plating,

gold plating, tin plating, copper plating and other processes

Related Project display

|

|

|

|