Chengdu Xingtongli Power Supply Equipment Co., Ltd. |

|

Verified Suppliers

|

|

water electrolysis IGBT power supply 12v 5000a with 4~20mA analog interface

Electrolysis of water is the decomposition of water into oxygen and hydrogen gas due to the passage of an electric current.

This technique can be used to make hydrogen gas, a main component of hydrogen fuel, and breathable oxygen gas, or can mix the two into oxyhydrogen, which is also usable as fuel, though more volatile and dangerous

Specification

| SPECIFICATIONS FOR GKD12-5000CVC | |||

| Input AC | 380V±10% | 3phase | 50/60Hz |

| Output DC | Volt | 0~12V Adjustable | |

| Current | 0~5000A Adjustable | ||

| Power | 20KW | ||

| Efficiency | >85% | ||

| output Frequency | 40KHz fixed | ||

| reverse | reverse time | 0~999hours optional | |

| reverse way | mannual/automatic | ||

| Protection | Short circuit protection Overheating protection Phase lack protection Input over/low voltage protection | ||

| Working Condition (Temperature) | -10℃~50℃ | Control mode | Panel control Remote control |

| Net weight | 280kg | Working mode | Constant Voltage(CV) Constant Current(CC) |

| Dimension(mm) | 1020*1000*1270m | Cooling way | water cooling |

Features

Using timing control function, the setting is simple and

convenient, and the working time of positive and negative current

polarity can be arbitrarily set according to the plating process

requirements.

It has three working states of automatic cycle commutation,

positive and negative, and reverse, and can automatically change

the polarity of the output current.

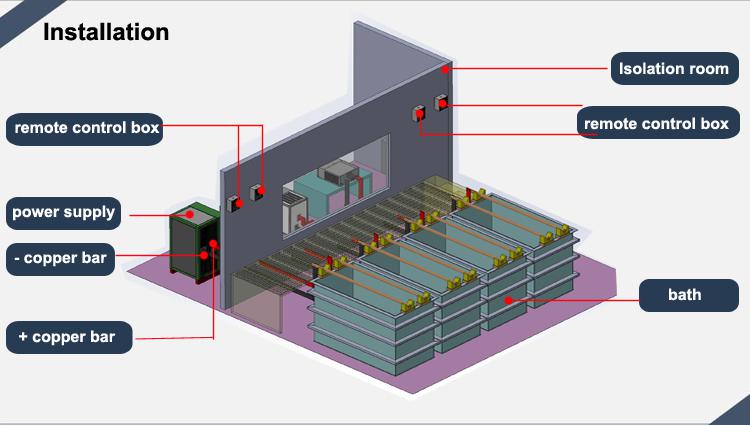

How to install rectifier

This is installation way for remote control rectifier. Not only

this way.

1. To connect copper bar with bath/tank

2. To ensure power supply/rectifier is grounded

3. To ensure there is enough water for water cooling type power

supply/rectifier

4. We advice that all rectifiers should be isolated to increase of

its life.

The superiority of periodic commutation pulse plating

1 Reverse pulse current improves the thickness distribution of the

coating, the thickness of the coating is uniform, and the leveling

is good.

2 The anode dissolution of the reverse pulse makes the

concentration of metal ions on the cathode surface rise quickly,

which is conducive to the use of a high pulse current density in

the subsequent cathode cycle, and the high pulse current density

makes the formation speed of the crystal nucleus faster than the

growth rate of the crystal, so The coating is dense and bright,

with low porosity.

3. The reverse pulse anode stripping greatly reduces the adhesion

of organic impurities (including brightener) in the coating, so the

coating has high purity and strong resistance to discoloration,

which is particularly prominent in silver cyanide plating.

4. The reverse pulse current oxidizes the hydrogen contained in the

coating, which can eliminate hydrogen embrittlement (such as the

reverse pulse can remove the co-deposited hydrogen during the

electrodeposition of palladium) or reduce the internal stress.

5. The periodic reverse pulse current keeps the surface of the

plated part in an active state all the time, so that a plating

layer with good bonding force can be obtained.

6. Reverse pulse is helpful to reduce the actual thickness of the

diffusion layer and improve the cathode current efficiency.

Therefore, proper pulse parameters will further accelerate the

deposition rate of the coating.

7 In the plating system that does not allow or a small amount of

additives, double pulse plating can obtain a fine, smooth, and

smooth coating.

As a result, the coating's performance indicators such as

temperature resistance, wear resistance, welding, toughness,

corrosion resistance, conductivity, resistance to discoloration,

and smoothness have increased exponentially, and it can greatly

save rare and precious metals (about 20%-50%) and save additives

(such as Bright silver cyanide plating is about 50%-80%)