Fuan Zhongzhi Pump Co., Ltd. |

|

Verified Suppliers

|

|

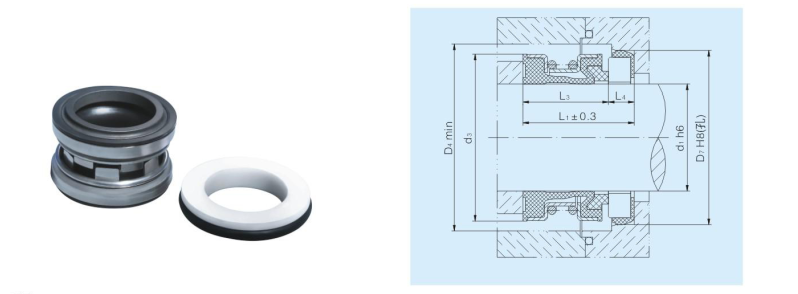

Mechanical Seal CN2100

Mechanical Seal CN2100 Description

High-temperature resistance

Fluorine rubber is resistant to 250 ℃, silicone rubber can be used

for a long time at -60 ℃ -250 ℃, butadiene rubber has oil

resistance, the use temperature is -55 ℃ -120 ℃

High wear resistance

Carbide, silicon carbide, car graphite, pressed graphite, and

alumina ceramics are manufactured with high-density, high-hardness

materials according to national standards, with high wear

resistance and long service life.

preservative

Fluorine rubber, ethylene-propylene rubber are resistant to various

corrosive liquids such as strong acid, alkali, saltwater, a strong

oxidant, organic solvents, etc.

Metal structure

Made of national standard 304 stainless steel material

Mechanical Seal CN2100 Design Features

- Single face, single spring, unbalanced, rubber bellows structure.

- The seal face is driven through the spring seat, rubber bellows

design to avoid torsion

- The installation size conforms to the standard for ISO3069 and

DIN24960

Mechanical Seal CN2100 Materials(to DIN24960)

- Rotary Ring: B, U1, U2, Q1, Q2

- Stationary Ring: U1, U2,Q1,Q2, V1,V2

- Auxiliary Seal: P, E, V

- Spring and Other Parts: F, G

Mechanical Seal CN2100 Operating limits

- Pressure: ≤ 2.0MPa

- Temperature: -40~150℃

- Speeds: ≤15m/sec

Mechanical Seal CN2100 Applications

Used in different pumps, mixers, compressors, and other

rotating equipment. which apply to oil, water, and other weak

corrosive

Mechanical Seal CN2100 Medium

Oil, water, and other weak corrosive fluid

Mechanical Seal CN2100 Size Information

| Model | d1 | d3 | D4 | D7 | L1K | L3 | L4 |

| CN2100-10 | 10 | 20 | 22 | 21 | 20 | 15 | 5 |

| CN2100-12 | 12 | 22 | 24 | 23 | 21 | 15 | 6 |

| CN2100-14 | 14 | 24 | 26 | 25 | 21 | 15 | 6 |

| CN2100-15 | 15 | 25 | 27 | 26 | 21 | 15 | 6 |

| CN2100-16 | 16 | 26 | 28 | 27 | 21 | 15 | 6 |

| CN2100-18 | 18 | 32 | 34 | 33 | 26 | 20 | 6 |

| CN2100-20 | 20 | 34 | 36 | 35 | 26 | 20 | 6 |

| CN2100-22 | 22 | 36 | 38 | 37 | 26 | 20 | 6 |

| CN2100-24 | 24 | 38 | 40 | 39 | 26 | 20 | 6 |

| CN2100-25 | 25 | 39 | 41 | 40 | 26 | 20 | 6 |

| CN2100-28 | 28 | 42 | 44 | 43 | 32 | 26 | 6 |

| CN2100-30 | 30 | 44 | 46 | 45 | 33 | 26 | 7 |

| CN2100-32 | 32 | 46 | 48 | 48 | 33 | 26 | 7 |

| CN2100-33 | 33 | 47 | 49 | 48 | 33 | 26 | 7 |

| CN2100-35 | 35 | 49 | 51 | 50 | 34 | 26 | 8 |

| CN2100-38 | 38 | 54 | 58 | 56 | 38 | 30 | 8 |

| CN2100-40 | 40 | 56 | 60 | 58 | 38 | 30 | 8 |

| CN2100-43 | 43 | 59 | 63 | 61 | 38 | 30 | 8 |

| CN2100-45 | 45 | 61 | 65 | 63 | 38 | 30 | 8 |

| CN2100-48 | 48 | 64 | 68 | 66 | 40 | 30 | 10 |

| CN2100-50 | 50 | 66 | 70 | 70 | 40 | 30 | 10 |

| CN2100-53 | 53 | 69 | 73 | 73 | 40 | 30 | 10 |

| CN2100-55 | 55 | 71 | 75 | 75 | 40 | 30 | 10 |

| CN2100-58 | 58 | 78 | 83 | 78 | 43 | 33 | 10 |

| CN2100-60 | 60 | 80 | 85 | 80 | 45 | 33 | 12 |

| CN2100-63 | 63 | 83 | 88 | 83 | 45 | 33 | 12 |

| CN2100-65 | 65 | 85 | 90 | 85 | 45 | 33 | 12 |

| CN2100-68 | 68 | 88 | 93 | 90 | 45 | 33 | 12 |

| CN2100-70 | 70 | 90 | 94 | 92 | 45 | 33 | 12 |

| CN2100-75 | 75 | 99 | 104 | 97 | 52 | 40 | 12 |

Application Picture:

Mechanical Seal CN2100

Installation Precautions

1. Assembly must be clean and smooth. The parts of mechanical

seals, related machinery and equipment parts, tools, lubricating

oil (grease), wipe materials (cotton yarn, white cloth, silk, etc.)

must be very clean. The sealing end face of the dynamic and static

ring should be wiped with white silk or soft gauze.

2. Trimming and chamfering of chamfers, shafts, sealed end caps,

etc. shall be trimmed smoothly, and the relevant corners of the

shaft and end caps shall be sanded and polished.

3. During installation, apply turbine oil or l0 oil on the moving

ring and static ring (especially on the seal end blood), auxiliary

seal ring, shaft, and end cap to reduce friction, so as not to

damage the seal of the static ring. End faces and auxiliary seals.

4. Assemble the auxiliary sealing ring.

1) Rubber auxiliary seals cannot be soaked and washed with gasoline

or kerosene to avoid swelling and deformation and premature aging.

2) After the O-ring is installed on the moving ring assembly or

static ring assembly, it should be logical to prevent it from being

twisted, so that the burr is in the cross-section when it is free.

O-rings that are slightly rough on the burr can be used if the burr

segment is 45o. However, care should be taken in the position of

the burrs. When pushing the component, one side of the O-ring and

the seal (gland or seal cavity) slide relative to each other. The

burr on the side should be behind the sliding direction. Otherwise,

the burr will be turned up and sealed. In position, it affects the

sealing effect.

3) When pushing the assembly, prevent the O-ring from being

damaged. The main forms of damage are drop, nick, bump, curl and

twist.

5. Adjust the mechanical seal compression amount according to the

technical requirements. For the value, refer to the product manual.

Otherwise, the amount of compression is too large, which increases

the specific pressure on the end face and accelerates the wear of

the end face; if it is too small, the specific pressure on the end

face of the moving ring and the dense ring is insufficient, and the

seal fails.

6. The static ring assembly should be installed into the gland (or

sealed cavity) using a press or a drilling machine. Under no

circumstances should mechanical seal parts or components be

impacted. The pressed surface should be covered with clean paper or

cloth to avoid damaging the sealed end.

7. After assembling the moving ring or static ring assembly, press

the compensation ring by hand to check whether it is installed in

place and whether it is flexible; elastic split ring (in some

mechanical seals, the elastic split ring axially positions the

compensation ring) Reliable positioning.

8. Check whether the perpendicularity between the sealed end and

the centerline of the shaft (or shaft sleeve) meets the

requirements.

9. The anti-rotation pin lead of the static ring component must be

accurate. When pushing the static ring component, the pin groove of

the component must be aligned with the pin. After pushing in place,

the distance from the end surface of the component to one end of

the sealed cavity is determined to determine whether it is in

place.

10. When tightening the end cap by tightening the bolts, use even

force, symmetry, and care. Tighten it several times. Do not tighten

it at one time to avoid skewing or even crushing the static ring.

11. After the moving ring is installed, it must be ensured that it

can move axially on the shaft flexibly (press the spring with the

moving ring and then spring back freely).

Mechanical Seal CN2100

Guarantee:

Guarantee for one year from shipped on board date. During the

guarantee period, our company will provide free easy-damaged spare

parts for problems caused by our quality of production or raw

material, except the damageable spare parts caused by the

customer's incorrect artificial operation. In addition, after

expiration, our company provides cost spare parts for

maintenance.

Our service:

1. Directly factory sale

2. Quick response to 2-8hours, response rates over 92%

3. 24 hours phone call is available, feel free to contact us.

4. All goods produced by ourselves, we provide one-stop services

from designing, printing to processing. Customers can provide the

design according to your request and samples making, also we can

advise how to make the products according to customers' target

prices.

FAQ:

1. Q: What’s the MOQ?

A: We accept one piece.

2. Q: Are you a factory or trading company?

A: We are a manufacturer.

3. Q: Can you accept using our logo?

A: Yes, we can do OEM for you.

4. Q: What’s the warranty period?

A: 1 year.

5. Q: What are the terms of payment?

A: T/T. 30% deposit and 70% against the BL copy or 100% LC at

sight.