Cangzhou Junxi Group Co., Ltd. |

|

Verified Suppliers

|

Shot Blasting A234 WPB 90 Degree Carbon Steel Elbow Pipe Fittings

Product Description:

For the butt Welded elbow , from the raw material division, we can divide the elbow into seamless elbow and erw elbow . From bend radius , we can divide the elbow in the LR elbow and SR elbow . According to the size and thickness ,we have American standard , Japan standard, DIN standard . Now we are mainly exporting the American standard .For the butt Welded elbow, we can get 24 inch seamless elbow and above 24 inch people will do two half elbow which need to weld the two half together . Now for the carbon steel elbow , we need the hot forming elbow machine to produce which use the induction heating machine .

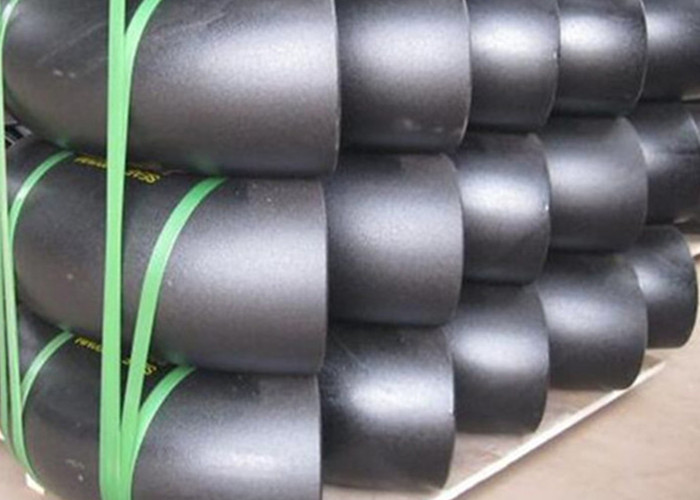

Please find the enclosed carbon steel pipe fitting photos :

| Carbon Steel Pipe Fittings |

| Product | 45/90/180degree elbow / tee / cap / reducer / bend |

| Type | seamless/erw/semi-seamless 1D-100D |

| Thickness | sch10,sch20,sch30,std,sch40,sch60,xs,sch80, sch100,sch120,sch140,sch160,xxs |

| Standard | ASME B16.9 ASTM JIS DIN |

| Size | 1/2”-120” |

| Surface treatment | bevelling,shot blasting,marking,painting according to customer requirement |

| Packaging | fabric bag & wooden box & pallet |

| Delivery | 10-15days |

Product Show

Seamless elbow classification:

A seamless bend is a fitting for a bend in a pipe.In the total pipe fittings used in the pipeline system, the proportion is the largest, about 80%.Generally, different forming processes are selected for the elbows with different material wall thickness.At present.The forming process of seamless elbow commonly used by manufacturers includes hot pushing, stamping, extrusion, etc

Seamless elbow is also called seamless steel pipe elbow, seamless elbow pipe fitting due to its manufacturing process, and divided into hot rolling (extrusion) seamless elbow pipe fitting and cold drawing (rolling) seamless elbow pipe fitting two kinds.Cold drawn (rolled) tube is divided into round tube and shaped tube two kinds.

The raw material for rolling seamless elbow pipe fittings is round tube blank. The round tube blank is cut by cutting machine and processed into blank with a length of about one meter, and then sent to the furnace by conveyor belt for heating.The billets are fed into a furnace and heated at a temperature of about 1200 degrees Celsius.The fuel is hydrogen or acetylene.The temperature control in the furnace is the key problem.Generally more common puncher is tapered roller puncher, this kind of puncher has high production efficiency, good product quality, large perforation diameter, can wear a variety of pipe fittings.After perforating, the round tube blank is successively rolled, rolled or squeezed by three high.After extrusion, take off the pipe to determine the diameter.The sizing machine rotates the tapered bit into the steel blank to punch holes at high speed to form the pipe fitting

Contact me:

Darcy Dong

Whatsapp/ Wechat: 008615630731167

Guozhong International Limited