Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

High Speed Conveying-Belt Direct-To-Textile Digital Inkjet Printer

☶ Application

| Digital Inkjet Textile Printing Machine | |

| Model | HM1800B |

| Print Head | Water-based Kyocera print head |

| Print Head Qty | 4-8 pcs |

| Max. Printing Resolution | 600x1800dpi |

| Production Speed | 600x600dpi(2pass): 260sqm/hr; 600x900dpi(3pass): 190sqm/hr; 600x1200dpi(4pass): 130sqm/hr |

| Printing Height | 2-30mm |

| Media Conveying | Continuous belt-conveying, Auto constant tension feeding&taking up, Fabric spreading, Tension-free entry unit(optional) |

| Max. Printing Width | 1900mm |

| Max. Media Width | 1920mm |

| Dimension(L/W/H) | Printer: 4656mm x 2304mm x 2277mm; Dryer: 2190mm x 2850mm x 1780mm; Package: 4850mm x 2250mm x 2250mm; Package: 2280mm x 2960mm x 1730mm |

| Ink Type | Reactive, acid, sublimation(direct or transfer), pigment |

| Ink Color | Cyan, Magenta, Yellow, Black + four spot colors(optional) |

| Ink Supply | Peristaltic-pump ink supply, Ink degassing, Auto negative pressure system |

| Belt Cleaning | Auto brush and sponge roller washing system |

| Media Type | Cotton, linen, silk, nylon, polyester, blended, elastic fabrics, etc |

| Max. Roll Diameter | 400mm (standard unwinder & winder roll) |

| Max. Roll Weight | 100kg (Full width, standard unwinder & winder roll) |

| Drying | Belt + Hot air + IR |

| Rip Software | Neostampa or Texprint |

| Power supply | Printer: AC380V three phase | 30A(6.5kW)+27A(6kW) | 50Hz/60Hz; Dryer: AC380V three phase | 22A(15.9kW) | 50Hz/60Hz |

| Compressed water supply | 0.6 Mpa | 0.9m³/hr |

| Compressed air supply | 0.6 Mpa | 0.15m³/hr(dry, no oil or water) |

| Working Environment | Temperature: 20~28ºC(68~77ºF); Relative humidity: 45-60%(no condensing) |

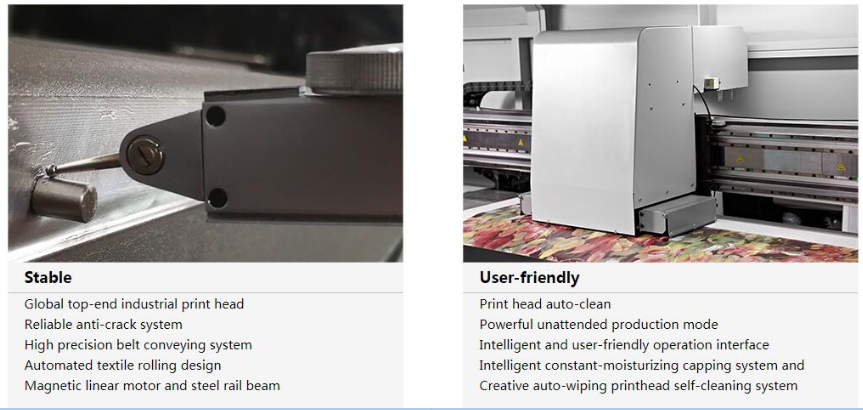

☲ Features

☷ Oversee

From producing to delivery, we make every details very carefully to

guarantee the good product quality and service to customers.

☱ Certificates

☰ FAQ

A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on. You can get the equipment and consumables all in one and

no worry about the after-sales service from our company. |

Q2: Where is your factory ? A: Our CTP Processor machine factory is in Shanghai, you are warmly welcome to visit our factory! |

A: The lead time is normally 30 days. We can accelerate for

emergency cases. |

Q4: Is there any certification for your machine ? A: Yes, all our machines have been certified by SGS and CE. |

A: EcooGraphix guarantees 1 year of warranty for laser head and

spare parts. |

Q6: What is your normal payment term ? A: Normally, 30% TT deposit, 70% before shipping, or LC at sight. |

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users(printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.

|