Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

6200PCS/H 1100x1450mm UV Spot And Overall Coating Machine

☼ Introduction

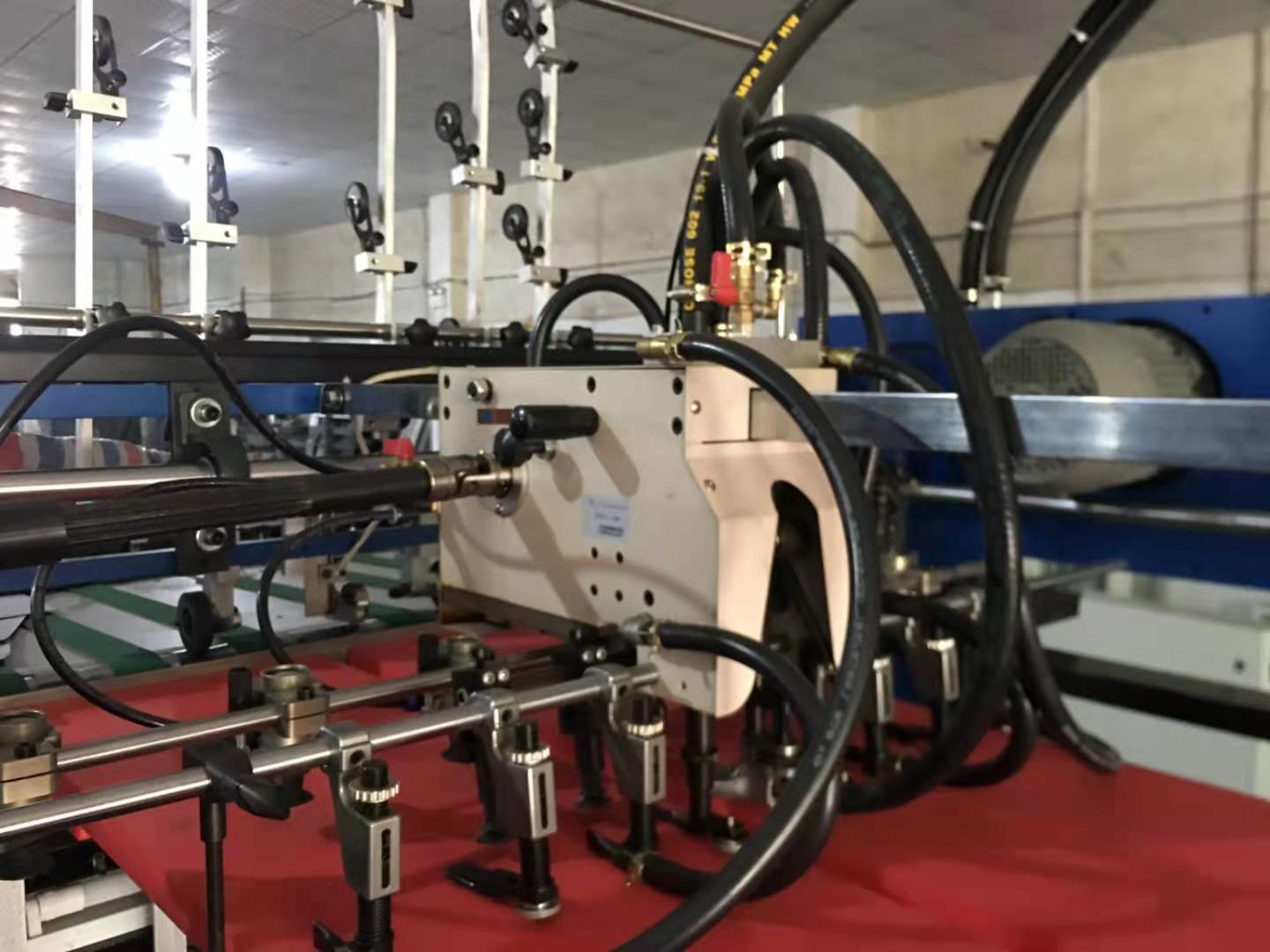

The HIS series of UV local glazing machine adopts the Bite-transferring structure and chain track design of offset printing pree. The drying section is a conveyor net structure, adopts the large diameter impression cylinder, so the finished oil film is very flat and even, accurate and bright. It can comprehensive think about both thick and thin papers, and can be used for both full UV and partial UV coating.

☽ Specifictions

| High Speed UV Spot And Overall Coating Machine | |||

| Model | ECOO HIS-1100 | ECOO HIS-1280 | ECOO HIS-1450 |

| Max. sheet size | 1100x1100mm | 1100x1280mm | 1100x1450mm |

| Min. sheet size | 310x406mm | 350x460mm | 350x460mm |

| Max. coating size | 1090x1090mm | 1090x1270mm | 1090x1440mm |

| Sheet thickness | 80-600gsm | 80-600gsm | 128-600gsm |

| Coating registration accuracy | ± 0.2mm | ± 0.2mm | ± 0.2mm |

| Production speed | 6800 sheets/hour | 6500 sheets/hour | 6200 sheets/hour |

| Weight | 8500kg | 9000kg | 9500kg |

| Dimension | 12010x2779x1818mm | 12230x2960x1844mm | 12230x3100x1844mm |

| Power | 50KW(E) 42KW(W) | 54KW(E) 44KW(W) | 57KW(E) 47KW(W) |

| Remark: Production speed depending on sheet weight, size and quality | |||

☀ Main Features

| Feeder Enlarged feeder with four sucking and six forwarding suckers and

air blowing for spool can feed sheet easily and smoothly. | |

Front Side Lay Gauge When sheet reaches front lay gauge, left and right pulling lay

gauge can be used. The machine can stop feeding immediately by

sensor without sheet and release pressure to keep bottom roller

under no varnish condition. | ||

| Varnish Supply Steel roller and rubber roller with metering roller reversing and

doctor blade design control by varnish consumption and volume to

meet the demand of products and operate easily. (Varnish

consumption and volume are determined by LPI of ceramic anilox

roller) | |

Transferring Unit After sheet is transferred from pressure cylinder to gripper, air

volume blowing for paper can support and reverse sheet smoothly,

which can prevent sheet surface from being scratched. | ||

| Conveying Unit Upper and lower conveying belt can form thin sheet to be curved for

smoothly delivery. | |

Sheet Delivery Automatic pneumatic patting sheet controlled by photoelectric

detecting sensor make sheet pile fall automatically and collect

sheet neatly. Electronic control can take out sheet sample safely

and quickly for inspecting. |

☾ Floor Plan

Standard Equipments:

| Optional Equipments: Non-stop Feeding and Delivery Mechanism Fold the Car Device Ceramic Anilox Roller |

☁ Producing And Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

★ Certificates

☆ FAQ

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on.

You can get the equipment and consumables all in one and no worry

about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP Processor machine factory is in Shanghai, you are warmly

welcome to visit our factory!

Q3: What is your warranty for the CTPs ?

A: Three years' Laser Head and main spare parts for the CTPs, one year

for the Processor.

If the customer uses EcooGraphix CTP plate with the CTP machine, we

will provide the Lifetime Warranty.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician

support ?

A: Our engineer can go to help the installation and provide the

necessary training. The buyer should take the round air plane

tickets, service charge and the local accommodation cost. Any

problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are

also many end users(printers) who have purchased the CTP products

from EcooGraphix China directly and EcooGraphix technical service

team support these installations remotely with regular onsite

visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.