Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

Print-on-Demand Digital Binder Fully Automated Single-Clamp Perfect Binder

❶ Introductions

Digital Robot 500C is a fully automated single-clamp perfect binder with Max. speed up to 360 cycles/hour. It features fully automated set-up through touch screen or via

barcode scanning, integrated thickness auto-measurement, short

changeover time for various binding formats, interchangeable EVA

and PUR system(option). Book of one production takes on a new level

of convenience and stability.

❷ Outstanding Features

❸ Specifications

Model

Digital Robot 500C

No. of Clamps

1

Max. Production Speed

400 books/h

Book Block Length (a)

120-370 mm

Book Block Width (b)

100-300 mm

Book Block Thickness (c)

1-60 mm

Cover Length (d)

120-370 mm

Cover Width (e)

220-620 mm

Power Required

11.5 kw

| Model | Digital Robot 500C |

| No. of Clamps | 1 |

| Max. Production Speed | 400 books/h |

| Book Block Length (a) | 120-370 mm |

| Book Block Width (b) | 100-300 mm |

| Book Block Thickness (c) | 1-60 mm |

| Cover Length (d) | 120-370 mm |

| Cover Width (e) | 220-620 mm |

| Power Required | 11.5 kw |

❹ Details

|

Touch Screen Control System The icon-based 10-inch touch screen enables ease of operation. Inputting required book format and production parameters on the touch screen or via scanning barcode, the set-up will be automatically finished in 30s at the fastest speed. The control system can memorize 99 jobs and be retrieved as requested.

|

|

Penumatic Book Clamp Simply put the book block in the pneumatic book clamps, book thickness will be automatically measured, and all revelvant work steps are set accordingly. The vibration unit aligns the book block precisely before the book clamps close. The double activation button and safety light curtain ensure high-safety operation.

|

|

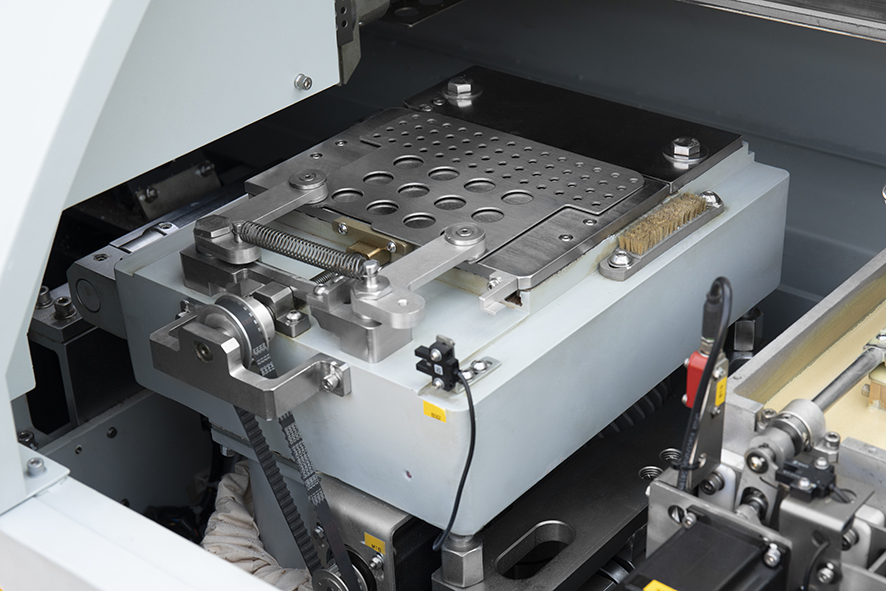

Milling Station Step motor allows milling station opening width to auto adjust

according to the detected thickness. While Space-saving design integrated milling and notching,

brushing. Operator can use switch handle to easily enable and

disable milling as needed. |

|

Moveable EVA Spine Gluing Station Dual spine gluing rollers guarantee top binding quality. Spine

gluing length and thickness are adjusted automatically and

accurately. Changeover between EVA and PUR system can be easily

completed in minutes. Independent Side Gluing Station Opening width of two side gluing rollers is automatically adjusted

by step motor. Even and thin side glue is applied by the

independent side gluing station with two application discs. |

|

Cover Feeding Station Top in-feed cover feeder design significantly reduce drag marks. Cover scoring position is automatically adjusted according to the input thickness; Sensitive double-feed and miss-feed defection device ensures accurate feeding for every cover.

|

|

Pneumatic Nipping Station The pneumatic controlled nipping station can be automatically adjusted at the fastest speed according to the book block thickness. Thanks to the accurate and reliable nipping mechanism, cover can be precisely and firmly nipped with the book block.

|

❺ Producing And Packaging

From producing to delivery, we make every details very carefully to

guarantee the good product quality and service to customers.

❻ Certificates

❼ FAQ

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on.

You can get the equipment and consumables all in one and no worry

about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP Processor machine factory is in Shanghai, you are warmly

welcome to visit our factory!

Q3: What is your warranty for the CTPs ?

A: Three years' Laser Head and main spare parts for the CTPs, one year

for the Processor. If the customer uses EcooGraphix CTP plate with the CTP machine, we

will provide the Lifetime Warranty.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician

support ?

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users(printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.