Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

Introduction:

Introducing the Ecoo Coating-760, a cutting-edge spot UV coating

machine offering outstanding performance. This equipment seamlessly

integrates advanced technologies from both domestic and

international sources. Capable of spot and overall coating, it

boasts high working speeds, and superior gloss, and produces thin,

uniform coating layers. Widely employed in packaging decoration,

book covers, and various printing materials, it sets new standards

in coating excellence.

Features:

1. One-Key Acceleration Function: The entire machine features a

convenient one-key acceleration function. Upon activation, the main

machine accelerates, synchronizing the speeds of the oven, paper

delivery system, feeder, and metering roller accordingly.

2. Anilox Roller for Precise Oil Application: Utilizes a metering roller anilox system for precise oil application, ensuring consistent coverage before transferring to the blanket.

Specification:

| Model | Ecoo coating-760 |

| Max.sheet size | 760x595mm |

| MIN.sheet size | 290X270mm |

| Sheet weight | 80-400gsm |

| Production speed | 6000 sheet/h |

| Power | 45kw |

| UV lamp | 3 pcs x 8 kw |

| IR lamp | 18 pcs x 1 kw |

| Paper feed heigh | 1050mm |

| Paper stack height | 920mm |

| Weight | 65000kg |

| Dimension | 9500x2050x2000mm |

Main Machine Parts:

Auto Feeding:

1. High-Speed Offset Press Feeder (12000 sheets/hour): Ensures fast

and stable operation.

2. Paper Photoelectric Control with Automatic Lifting: Enhances

efficiency and automation.

3. Double Protection Feeder Lifting Safety: Ensures safety during

operation.

4. Latest Pre-Stacker Design for Continuous Paper Feeding:

Significantly reduces paper wastage and operator labor intensity.

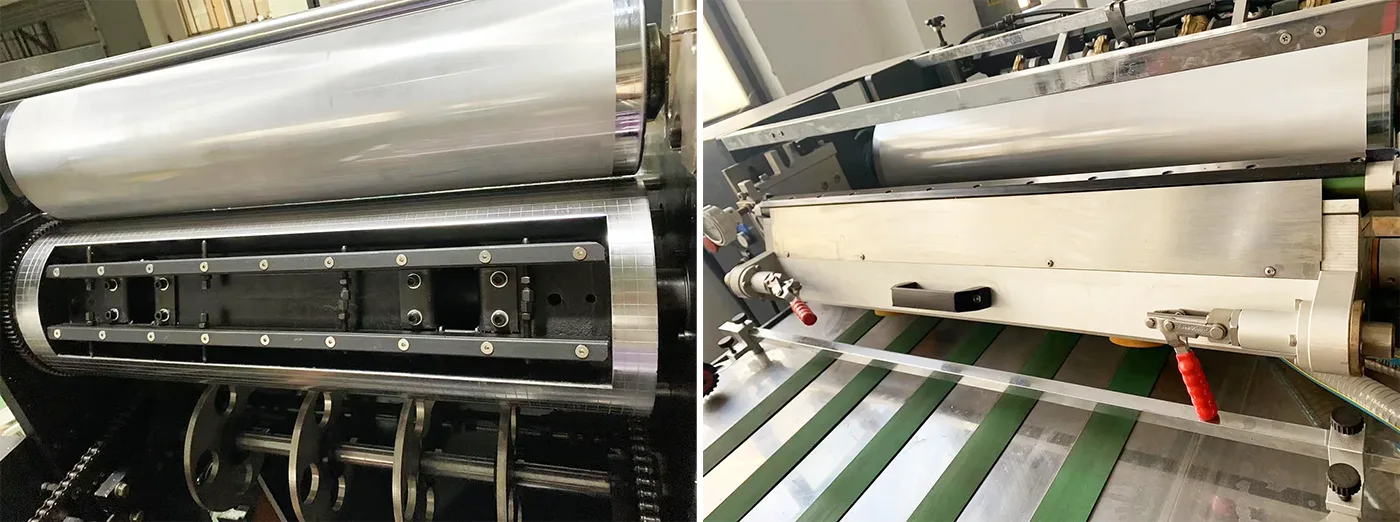

Coating Section (Basic Oil Coating Head):

1. Anilox Roller for Uniform Oil Supply: Delivers consistent oil

weight (80-120 mesh) with the option to choose different oil types

to achieve 3-10 grams of coating oil per square meter.

2. Closed Scraper Design: Circulates oil within the oil circuit,

minimizing oil loss and volatilization.

3. Offset Press Feeding Mechanism: Accommodates paper of varying

thicknesses, ensuring smooth operation.

4. Photoelectric Control for Automatic Pressing: Prevents oil

spillage on the backside in the absence of paper.

5. Engraved Plate Roller for Easy Alignment: Facilitates seamless

plate pasting with network cable engraving for precise alignment.

IR Drying and UV Curing System:

1. Length of Oven: 4300mm, ensuring effective leveling and curing

strength.

2. Dual UV and IR Systems: Controlled separately, cannot operate

simultaneously.

3. Lamp Configuration: 18 IR lamps and 3 UV lamps. IR lamps

typically last 2 years, UV lamps have a lifespan of 800~1000 hours,

and transformers last more than a year.

4. Enhanced UV Part: Utilizes an 8KW adjustable electronic light

source for improved safety—automatic brightness adjustment based on

machine speed, saving over 30% energy on average.

5. Safety Features: Emergency stop and overheat protection. The

protective cover automatically rises if the temperature exceeds 150

degrees, dissipating heat to prevent fire.

6. Ventilation System: Located under the UV curing box, featuring a

strong suction device composed of an exhaust fan and wind box.

Extracts ozone, dissipates heat, and prevents paper from curling in

the furnace.

7. Automatic Correction System: Double correction with double

over-limit protection. Utilizes imported Teflon conveyor belt for

UV protection, durability, and paper support. The electric eye

detects the belt, enabling automatic homing correction.

8. Efficient Product Handling: Ensures coating products remain

stable without floating or paper piling. Oven equipped with iron

wire protection to prevent paper floatation and fire hazards.

Cooling system:

After the paper dries out, it is quickly air-cooled to make the

paper dry faster without anti-sticking.

Automatic delivery system:

1:Paper photoelectric control, automatic lifting

2:Double protection feeder lifting safety

3:Equipped with pneumatic paper flap function, you can set the

number and time of the paper beat to ensure neatness

4:Disorderly paper automatic lowering function.