Hangzhou Ecoographix Digital Technology Co., Ltd. |

|

Verified Suppliers

|

|

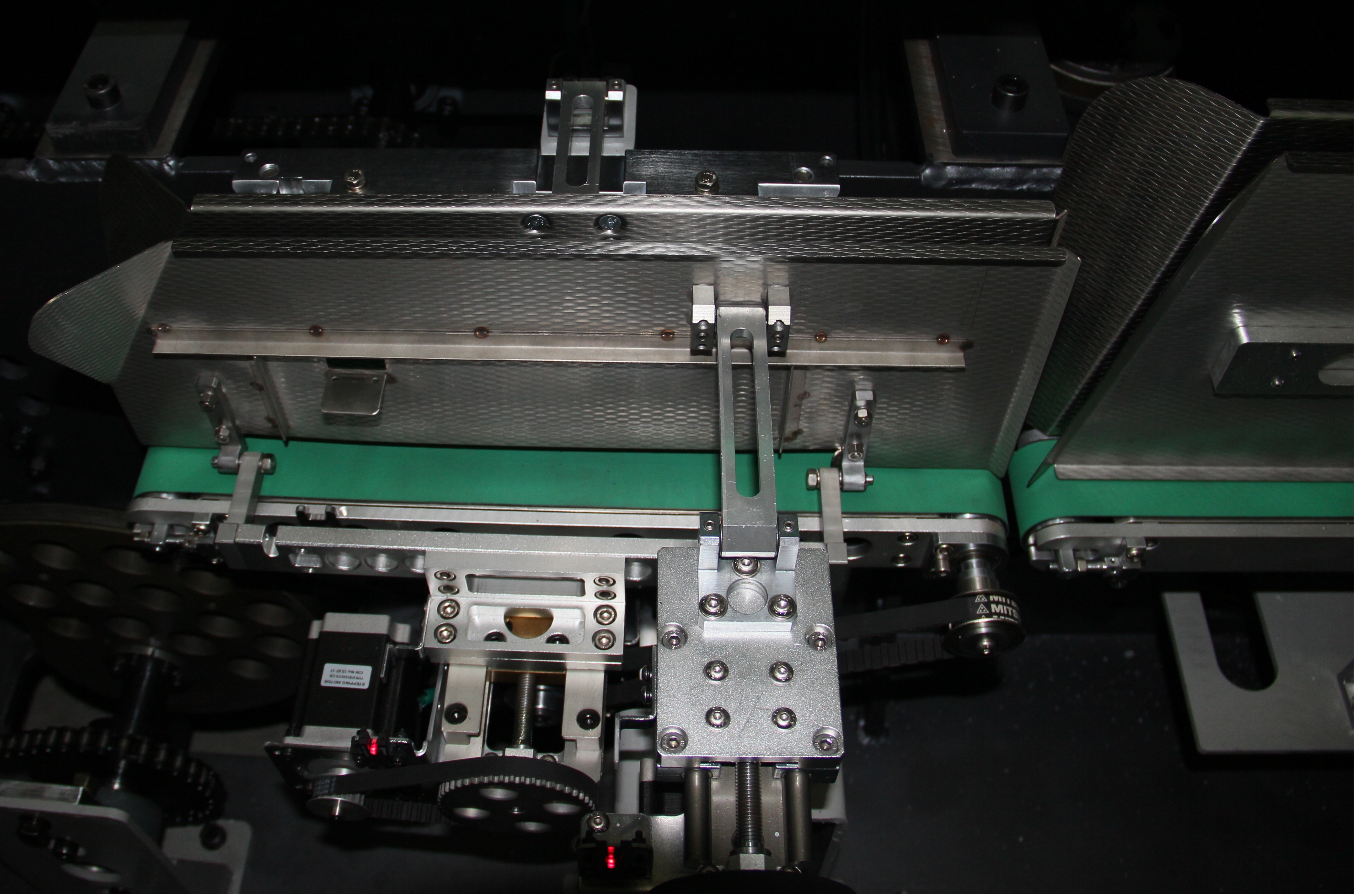

Digital Robot 2000C Binding Machine

| Items | Standard Configurations | Quantity (pcs) |

| a. | Vertical Turning Module | 1 |

| b. | Robot Arm | 1 |

| c. | Digital Robot 2000C Binder (Hotmelt EVA Version) | 1 |

| d. | DS-50 Digital Stacker | 1 |

| e. | DT-30 Three-Knife Trimmer | 1 |

| f. | Conveyor for connecting DS-50 Stacker and DT-30 Trimmer | 1 |

Features

Specification

| Machine Model | Digital Robot 2000C Binder |

| No. of Clamps | 4 |

| Max. Mechanical Speed | 1600c/h |

| Book Block Length (a) | 140-320mm |

| Book Block Width (b) | 140-270mm |

| Book Block Thickness (c) | 3-50mm |

| Cover Length (d) | 140-330mm |

| Cover Width (e) | 240-590mm |

| Power Required | 28kw |

Producing Main Spare Parts

A digital central control system

The icon-based touch screen in the binder serves as a central

control system that can control all the modules and monitor their

working status, and also serves as an error indicator to help

maintain smooth operation.

A book block feeding station

After the book block is fed into the book clamp, vibration will be

applied to vibrate the book spine. The height of book block feeding

station can be adjusted.

Four automatic adjusted book clamps

The pneumatic controlled book clamps can be automatically adjusted

according to the book block thickness.

An automatic adjusted milling station

Opening width of milling pressure plate is automatically adjusted

by step motor.

Function: milling and notching, brushing. Milling depth: 0~3mm.

If milling function is not needed, just switch the milling handle

to lower the milling station, so that book blocks are not to be

milled.

An automatic adjusted moveable spine gluing station

Spine gluing tank is moveable, and could be changed by JMD Twin

Roller PUR glue tank or Nordson PUR nozzle glue tank as option. The

spine gluing length and thickness are adjusted automatically.

An automatic adjusted side gluing station

Opening width of two side gluing rollers is automatically adjusted.

An automatic adjusted cover feeding station (quadruple cover

scoring)

The side gauges of cover feeding station and position of cover

scoring wheels are automatically adjusted. Sensitive double-feed or

miss-feed cover defection device is installed to ensure accurate

cover feeding.

An automatic adjusted cover feeding station (quadruple cover

scoring)

The side gauges of cover feeding station and position of cover

scoring wheels are automatically adjusted. Sensitive double-feed or

miss-feed cover defection device is installed to ensure accurate

cover feeding.

An automatic soft book lay-down system

The soft book lay-down system works as an auto-lift conveyor to

receive and transport bound books gently so as to ensure no slight

deformation to the book spine during delivery.

A paper dust extractor

Paper waste can be removed by the powerful paper dust extractor to

keep the system clean.

More details

FAQ

Q: What about the Installation and after-sales technician support?

A: Our engineer can go to help the installation and provide the

necessary training. The buyer should take the round air plane

tickets and service charge and the local accommodation cost. Any

problems or questions, we will be at your disposal 7x24 hours.

Among our large amount of CTP installations worldwide, there are

also many end users (printers) who have purchased the CTP products

from EcooGraphix China directly and EcooGraphix technical service

team support these installations remotely with regular onsite

visits.

These end users Printers all run the CTP systems with full

satisfaction due to our robust quality, seamless remote service,

thorough training and maintanence. If you are a printer who is

considering purchasing directly from EcooGraphix China, there is no

hasle on installations, training and after sales service. We

guarantee your satisfaction.