Changsha Chaojingang machinery manufacturing CO., Ltd |

|

4 inch Hard Rock Drill Bits DTH Drill Bits For Water Well Blasting Drilling

The Drill Bits are made up of grade hard alloy and special steel, usually matched with the rock drill, to drill the rock. The drill tools are utilized in science mine, geologic exploration, water conservancy construction, electricity, traffic, tunnel, quarry, national defence stone project etc.

| Product Name: | DTH Drilling Hammers And Button Bits With Long Service Life | |||||

| Description: | dth drilling hammers and button bits DTH hammers are used for high air pressure mining dth hammerblast hole drilling and water well drilling project. Working with DTH drilling pipe and DTH drill bit, mainly applied in Mining, Marble quarry or well drilling and other construction projects. | |||||

| Quality level: | 95% similarity to COP/SD/MISSION/QL/BR/DHD etc famous brand | |||||

| MOQ: | No requirement for testing and trial order | |||||

| Diameter | No ×Button diameter , mm | Button angle° | Flushing holes | Weight(Kg) | Part No | ||

| mm | inch | Gauge Buttons | Front Buttons | ||||

| 105 | 4 1/8 | 6×φ14 | 5×φ13 | 38 | 2×φ18 | 7.5 | CD45-105 |

| 110 | 4 5/16 | 7×φ14 | 6×φ13 | 38 | 2×φ18 | 7.8 | CD45-110 |

| 115 | 4 1/2 | 7×φ14 | 7×φ13 | 38 | 2×φ18 | 8.5 | CD45-115 |

| 120 | 4 3/4 | 8×φ14 | 7×φ13 | 38 | 2×φ18 | 8.8 | CD45-120 |

| 125 | 4 15/16 | 8×φ14 | 7×φ13 | 38 | 2×φ18 | 9 | CD45-125 |

| 130 | 5 1/8 | 8×φ14 | 7×φ14 | 38 | 2×φ18 | 9.4 | CD45-130 |

Feature Advantage:

1. We have professional engineer to design the product.

2. We will stick to the safety bottom line of our products.

3. Forged alloy steel helps save the raw material.

4. Every part of our products is properly assembled and uses the highest quality steel.

5. The production workshop uses the most environmentally friendly steel as raw material.

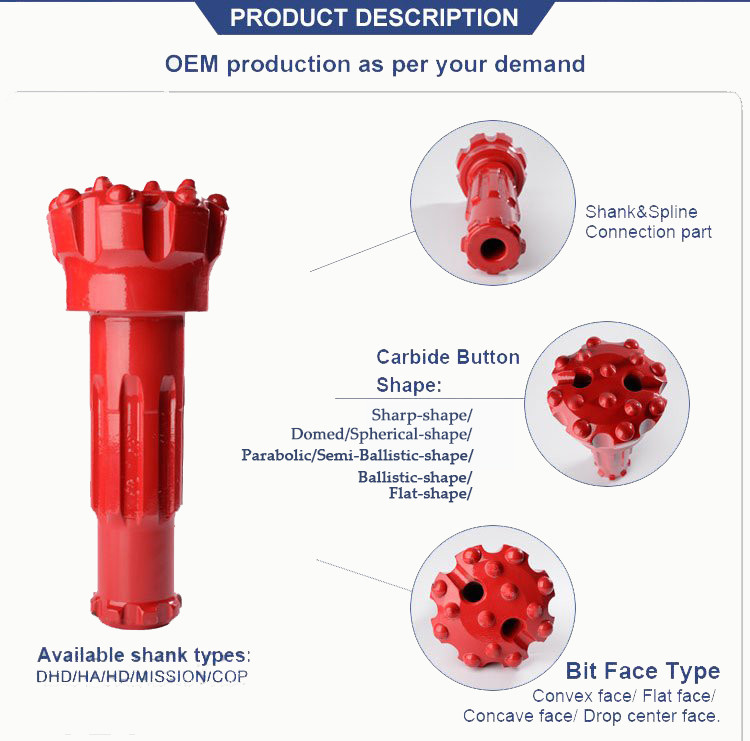

Bit face shape selection:

1. Drop Center Bit

For high penetration rates in soft to medium hard and fissured rock

formations. Low to medium air pressures. Maximum hole deviation

control.

2. Concave Face

The all-round application bit face specifically for medium hard and

homogenerous rock formations. Good hole deviation control and good

flushing capacity.

3. Convex Face

For high penetration rates in soft to medium-hard with low to

medium air pressures. It is the most resistance to steel wash, and

may reduce the load and wear on the gauge buttons, but poor hole

deviation control.

4. Double Gauge Face

This kind of face shape is suitable for fast penetration rates in

medium to hard rock formations. Designed for high air pressures and

good resistance to steel wash step gauge bit.

5. Flat Face Bit

This kind of face shape is suitable for hard to very hard and

abrasive rock formations in applications with high air pressures.

Good penetration rates an resistance to steel wash.

| Caibide BUtton Shapge |  | Domed / Spherical Button Domed / Spherical Buttons are usually used as gauge buttons of DTH Bits, suitable for very abrasive and very hard formations. |

Parabolic / Semi - Ballistic Buttons Parabolic Buttons are usually used as gauge buttons and front buttons of DTH Bits, suitable for medium abrasive and hard formations. | ||

| Ballistic Button Ballistic Buttons are usually used as front buttons of DTH BIts, suitable for medium abrasive and medium hard formations. They can also be used as gauge buttons if the rock is soft. | |

Sharp Button Sharp BUttons are usually used as front buttons of DTH bits for soft formations where fast penetration rates are possible and button breakage is minimal. | ||

| Flat Button Flat buttons are usually used as protection buttons to reduce wear on rubbing surfaces of DTH bits. |

FAQ

1.The Quality of Drill bit?

We have many series of rock bits,quality grades are different,and prices are different.We believe,the proper tools with higher cost-performance isthe most impormant.

3.How to send inquiry?

It is better send us detailed specificaltions of products,it is better attaching some photos for better understanding.If you are not experienced on drilling fields,for example,many customers don't know IADC code,please feel free,jusst tell us the applications like oil/gas/geothermal/HDD/ware/mining,depth of well,average hardness of rocks,then we will advise suggestions and solutions.