Zhengzhou MG Industrial Co.,Ltd |

|

Verified Suppliers

|

|

Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant

1,Description of Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant.

The Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant is an automatic powder mixing equipment. The proposed mixing station consisting of a combination of a twin-shaft mixer and a batching system can fully utilize the advantages of the batching system and the mixer. The operation is simple and convenient. The Chinese and English menus show that the status of each device is simulated and displayed with an audible and visual alarm. When working at the mixing station, after only a small number of buttons are operated, the entire work process is transferred to the computer control.

2.Advantages of Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant.

The main components of this production line:Raw material storing system,automatic weighing system,conveying system,mixing system,pneumatic system,packing system and dedusting system,the main control system administrate the production order based on fixed formula ratio,thus the production line dosing the coarse materials from storage silos,after automatic weighing,the material will enter in premix tank and high efficient agravic mixer continuously,to mix in a short period (3-5min). The well mixed material will discharge into the holding tank,which will make secondary mixing,then down to new designed automatic filling and packing machine,the packing machine work efficiently based on fixed time and volume,it increase the capacity sharply,well packed finished mortar will be transferred to finished mortar area,ready for sale.

The advantages of our Automatic dry mortar mixing equipment.

1, A high degree of intelligence. It is controlled by the control system and realizes automatic automation of automatic batching, automatic weighing, automatic feeding, automatic mixing and automatic packaging.

2, The ingredients are accurate, can automatically calculate the error and automatically correct.

3, The use of tower layout structure, shorten the transmission distance and increase production efficiency.

4. The use of a biaxial mixer( Twin shaft mixer) has high mixing uniformity, and materials with large differences in physical properties such as specific gravity, particle size and shape do not easily segregate when mixed in the mixer.

| Model | Capacity | Equipment height | Total power | Worker required | Workshop required |

| 2000L Mixer | 10-12T/H | 8-10m | 80-90KW | 2-3 Person | 500-600m2 |

| 3000L Mixer | 15-20T/H | 10-14m | 90-100KW | 3-4 Person | 600-800m2 |

| 4000L Mixer | 20-30T/H | 10-14m | 100-120KW | 3-4 Person | 600-800m2 |

| 6000L Mixer | 30-50T/H | 15-20m | 100-120KW | 3-4 Person | 800-1000m2 |

| 10000L Mixer | 50-80T/H | 20-25m | 120-150KW | 3-4 Person | 1000-1200m2 |

3. Raw Material of Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant.

Raw materials are: Cement, Sand, Gypsum, Flyash, Gelatine powder, Cellulose and Additives etc.

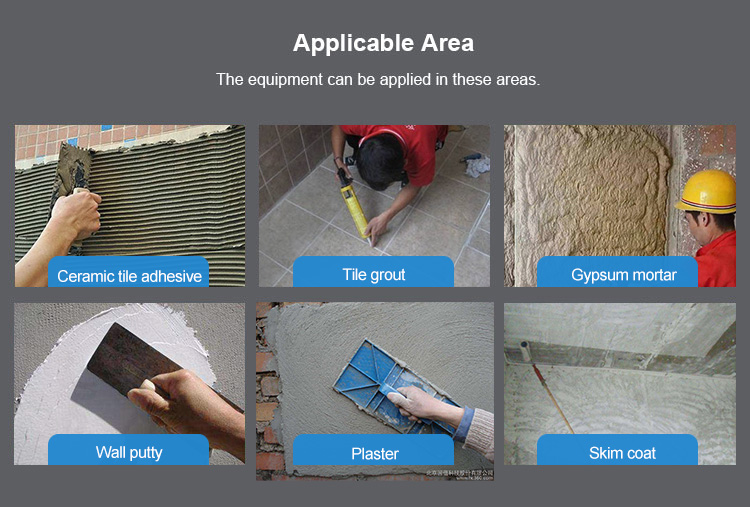

4. Application of Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant.

Applications of dry mortar production line The simple dry construction mixture mixing plant can produce the following dry mortars:

Bonding mortar: Masonry mortar, wall and floor tile adhesive mortar, anchorage mortar etc.

Decoration mortar: Decorative plaster, inner and outer wall putty, colorful decoration mortar etc.

Protection mortar: Water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, thermal insulation mortar, sound insulation mortar, repair mortar, mildew-proof mortar, shielding mortar etc.

5. Configuration of Energy Saving Wall Putty Skim Coat Tile Glue Dry Mortar Plant.

1,Raw Material Storage Silo:

Customized volume 150T, 100T, 60T, Easy transportation, waterproof manufacturing and reasonable design.

The silo is used to store dry building raw material powder, such as sand, cement, fly ash, slag, calcium carbonate powder and so on. MG standard silos will equips level regulars, air breaking device, e-dust collector, pressure safety valve and complete set of assemble accessories. When material feeding air breaking device can help air exhausting from silo inside, e-dust collector clear the dust on the top; Level regulars can detect the maximum and minimum of material in hopper, so that to remind people feed material timely; Safety valve is to prevent material discharge easily. Material can discharge quickly when it works with screw conveyor.

2,Bucket elevator.

High efficient, Good sealing, Easy assemble, Environment protection, Easy maintenance.

This is a vertical lifting device. Lifting height can reach 20-35m, with high efficient lifting speed and large transport capacity, bucket elevator is widely to used to lifting all kinds of powder or granular material. There are belt type bucket elevator and chain type bucket elevator two kinds for customer choice. Chain bucket elevator can be lift heat material and capacity is higher, lifting height is higher.

3, Automatic weighing system.

High efficient self-measurement, Highly sensitive, High accurate digital display.

This is an automatic batching system that greatly saves manpower and material resources. Machine around equips three S-type sensors, which can get exact value when machine running. Input the weight of each raw materials accordingly to the formulation, high precision, reduce weighing error,save labor cost, improve the output.

4,Twin shaft agravic paddle mixer.

High Efficiency, equip with fly cut for fiber breaking, Mixing time 3-5 minutes per batch.

This twin shaft paddle mixer have the characters of high mixing speed, high uniformity, less power consumption. Materials with large differences in physical properties such as specific gravity, particle size, and shape do not easily segregate when mixed in the mixer. The material discharge is by pneumatic control, material can be discharged within 3-5 seconds.

5,Automatic packing machine.

High accuracy, high speed, Equip bag auto pushing system.

The packing machine use computerized metering devices provides accurate weighing, stable performance and simple operation. And equipped with dust mouth, truly environmentally friendly production. Packing machine is PLC control, more intelligent. It can equip with bag belt conveyor and robot palletizer work.

6,Pulse dust collector.

High efficiency, strength dust collecting, pulse controller control.

The Impulse dust collector is mainly designed for dry mortar machine dust collecting, it equip pulse solenoid valve and can realize automatic dust remove. This dust collector is compact in structure, convenient in maintenance, which has the characteristics of large ash removal kinetic energy and high ash removal efficiency. It use special fabric filter dust, well dust collect. Fans,Cloth cylinder and filter assembly as one, can shorten the wind mesh simplify workmanship process.

7,Control cabinet.

Famous brand PLC, Intelligent and computer control.

PLC control system with characters of High degree of intelligence, automatic control from the Raw material storage silo, screw conveyor, weighing of ingredients to the mixing, packaging and full control of the complete set dry mortar plant, Intelligent and easy operation.

6.Our company.

Zhengzhou MG Industrial Co,.Ltd,one of the leading manufacturers of

building material equipment in China,always provides the customers

from all over the world with professional efficient solutions to

high quality machine,formula technology and special additives for

more than 20 years.

The main products of the company include dry mortar plant,thermal

insulation mortar production line,sand dryer powder blending

machine,impulse dust collector,automatic packing machine,and so on.

MG products have been widely used in more than 1000 building

materials enterprises in China,and exported to more than 50

countries,such as Canada,Russia,Korea,Malaysia,the United Arab

Emirates,Argentina,Chile,Ecuador,Morocco,South Africa,Nigeria,etc.

MG will be willing to work with you to seek common development and

create brilliance.

Welcome to inquiry on our products

7.Our Services

Pre-sale service

1) Once got your inquiry, we will reply to you in 24 hours;

2) High quantity and quantity assured;

3)Favorable price as we are manufacturer;

4) Provide professional technical and project;

solutions online or by telephone ;

5) Well-trained and experienced staff to answer all your inquiries

in fluent English and Russia;

6)OEM & ODM is welcomed. OEM brand is available;

7)Assist clients to prepare for the first construction scheme and

supply foundation drawing.

After-sale service

1) Assist clients to prepare for the first construction scheme and

supply foundation drawing.

2)Oversea installation and provide technical exchange, train client

to operate the machine.

3) Supply spared and accessory parts at favorable price for

long-term.

4)Spare part are original, authentic, good quality.

5)They can be available from stock, and sent to clients,

immediately by sea, guarantee clients to receive it in shortest

time.

6) Providing following up after-sale service.

7.FAQ.

1, How about the investment of this project?

A: Our engineer can design the dry mortar mixing equipment as your requirement and your budget, different dry mortar mixing equipment investment are difference.

Low capacity low cost, we will provide you cost effective solutions as your requirement.

2, What's the difference between full automatic dry mortar mixing equipment and Semi-automatic dry mortar mixing equipment?

A: (1)Semi-automatic dry mortar mixing equipment is cheaper than full automatic dry mortar mixing equipment.

(2) Semi-automatic dry mortar mixing equipment do not need to equip silos while full automatic dry mortar mixing equipment equip material silos.

(3) Semi-automatic dry mortar mixing equipment is manual feeding and automatic weighing and packaging, Full automatic dry mortar mixing equipment is automatic feeding and automatic weighing and packaging.

3, How many person required to operate this dry mortar mixing equipment?

A: Usually 2-4 workers are enogh to operate this dry mortar mixing equipment.

4, What equipment and services you can provide?

A: We can provide you turnkey solution of dry mortar mixing equipment from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after-sales services, life time technical support etc.

5, What is the area required for this dry mortar mixing equipment?

A: According to the capacity of the dry mortar mixing equipment, the area required 300-100 m2.

6, What is the total power consumption (KW) of this dry mortar mixing equipment?

A: It is 20-80W based on the capacity of the dry mortar mixing equipment.

If you are interested to our dry mortar production line, please

feel free to send us inquiry or leave your contact number for us.