- Jaw crusher parts must have some wear after a period of use, but

the easily damaged parts will wear out more.

- The price of crushing equipment with the same specifications and

handling capacity is different in the material of parts.

|

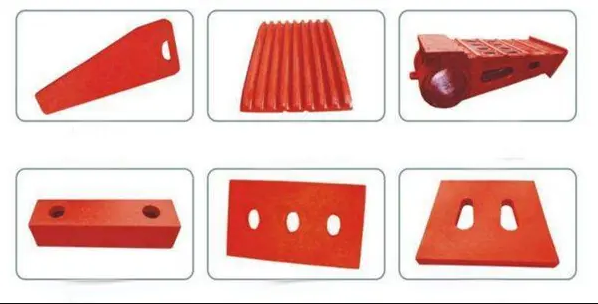

| Guard Plate | - The guard plate is made of high-quality high manganese steel, which

is located between the fixed plate and the movable plate.

- The whole body is mainly to protect the jaw crusher frame wall.

|

| Toothed Plate | - Tooth plate is divided into movable and fixed tooth plate, but both

is made from high manganese steel casting.

- In order to prolong its service life, its shape is designed to be

symmetrical. That is when one end of the wear can be used to turn

the head.

- The movable and the fixed teeth plate are the main parts for stone

crushing. So the movable teeth plate is installed on the movable

jaw to protect the movable jaw.

|

| Toggle Plate | - The toggle plate is a cast iron piece that has been precisely

calculated.

- It is not only a force transmission component but also the safety

parts of the crusher.

- When the crusher falls into the non-crushing material and makes the

machine beyond the normal load, the toggle plate will immediately

break.

- Then the crusher machine stops operation, thus avoiding the damage

of the whole machine.

- The toggle plate and the toggle plate spacer adopt the rolling

contact model which less attrition under normal use. It just needs

smear a layer of grease on the contact surface is ok.

|

| Triangular Belt | When the motor transmits power, the triangle belt is connected with

the pulley and the grooved pulley of the motor to drive the

eccentric shaft and make the moving jaw move back and forth

according to the predetermined track. |

- The tooth plate of the most jaw crushers are made of manganese

steel, bearing linings are made of babbitt alloy, sliding blocks

are made of carbon steel, toggle plates are made of cast iron,

springs are made of 60SiMn. Regular Inspection and maintenance of

the machine can extend its service life.

- In order to reduce customer costs, we will generally be in the

purchase of customers are advised to buy some spare parts.

- Because once the parts need to be replaced, the temporary purchase

will take some time. The wait time may cause the entire breakage

line to suspend operations, thereby increasing operating costs.

|