Henan Mind Machinery Equipment Co., Ltd. |

|

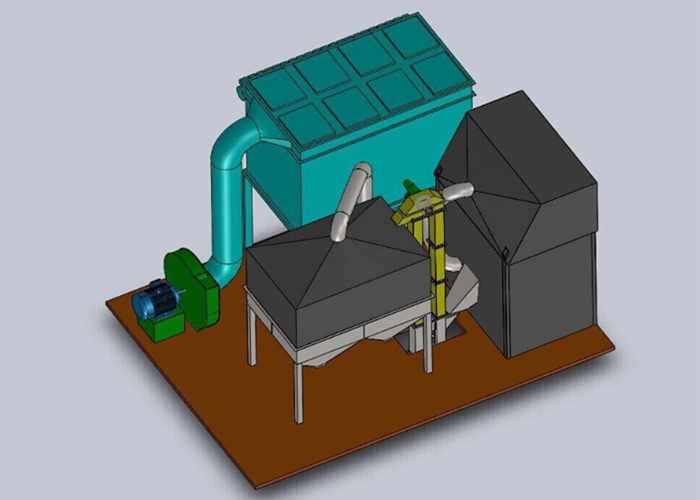

1. A dust collector is a system used to enhance the quality of air

released from industrial and commercial processes by collecting

dust and other impurities from air or gas.

2. Designed to handle high-volume dust loads, a dust collector

system consists of a blower, dust filter, a filter-cleaning system,

and a dust receptacle or dust removal system.

3. It is distinguished from air purifiers , which use disposable

filters to remove dust.

| Model | Air valume | Filter area | Filter bag | Pulse valve | Power | Body size | Weight |

| (m³/h) | (m²) | (piece) | (piece) | (kw) | (mm) | (kg) | |

| DMC-02MQ36 | 1500-2100 | 24 | 36 | 4 | 4 | 1180*1180*4150 | 750 |

| DMC-03MQ48 | 2100-3200 | 36 | 48 | 6 | 5.5 | 1520*1180*4250 | 850 |

| DMC-04MQ64 | 2900-4300 | 48 | 64 | 8 | 7.5 | 1520*1520*4450 | 950 |

| DMC-05MQ80 | 4000-6000 | 60 | 80 | 10 | 7.5 | 1860*1520*4650 | 1050 |

| DMC-06MQ100 | 5200-7000 | 72 | 100 | 12 | 11 | 1860*1860*4800 | 1200 |

| DMC-07MQ120 | 6000-9000 | 84 | 120 | 14 | 13 | 2200*1860*4950 | 1400 |

1. Dust-containing gas enters the ash hopper from the air inlet or

enters the bag room through the open flange. The dust-containing

gas is filtered into the clean room through the dust-removing cloth

bag, and then passes through the air outlet of the clean room and

is photographed by the fan. go.

2. Dust accumulates on the outer surface of the dust bag and keeps

increasing, so that the bag dust collector continues to rise. In

order for the equipment to overcome no more than 1200Pa, the bag

dust collector can continue to work, and it is necessary to

periodically remove the dust on the bag.

3. The dust cleaning is to start the pulse valve in sequence by the

program controller, so that the compressed air (0.5-0.7MPa) in the

bag is ejected from the nozzle hole (called primary air) and the

ambient air is sensed by the venturi tube several times than the

primary air. (Referred to as secondary air) entering the cloth bag

causes the cloth bag to expand rapidly in an instant, and the dust

is shaken off with the reverse effect of the air flow to achieve

the purpose of dust removal.

1. Cabinet: Including bag room, air purifying room, perforated plate, dust-removing cloth bag, skeleton, maintenance door, and box with a design pressure of 5000Pa

2. Air outlet system: Including fan and fan equipped with motor.

3. Blowing system: including main air pipe, blowing pipe, pulse valve and controller.

4. There are three forms of the ash exhaust part of the air intake:

a. the standard belt ash bucket type; b. the drawer type; c. a gray silo style

1. Complete with computer design, design accurate and reliable.

2. The shell adopts frame structure with high strength, good

stability,also can designed by different pressure and temperature

requirements.

3. The ways of gas in or out can be arranged according to

characteristics of the design process into various forms, process

layout flexibility.

4. Using the resistance type air flow plus uniform diversion

device, the air uniform, and no blocking phenomenon.

5. Precipitation using 480C plate board, discharge tube prick using

the new RS line, most with the management, discharge uniformity,

discharge performance.

6. The discharge electrode connected with the framework of the

rational, no dropped calls, disconnected situation.

7. Lateral torsion arm hammer rapping, rapping uniform and

effective force transmission, cleaning easy.

Application:

1) Welding fume, foundry

2) Food, pharmaceutical

3) Shot blasting

4) Tobacco, metal, painting

5) Energy