Henan Mind Machinery Equipment Co., Ltd. |

|

1) Raymond mill is a commonly used milling equipment, mainly used

for calcite, feldspar, talc, marble, limestone, dolomite, fluorite,

lime, activated clay, activated carbon, kaolin, cement, phosphate

ore, gypsum, glass, insulation materials with Mohs hardness not

more than 9.3 degree.

2) Raymond mill for size reduction, fine powder, ultra fine powder

grinding with finished products from 100 mesh to 325 mesh . It was

ever popular in mining, building materials, chemical engineering

and metallurgy industries for size reduction, dispersion, or

specialized needs, powder generation and processing for industrial

process. Raymond grinding mill is suitable for primary grinding,

secondary grinding, re grind applications, fine grinding, lime

slaking etc.

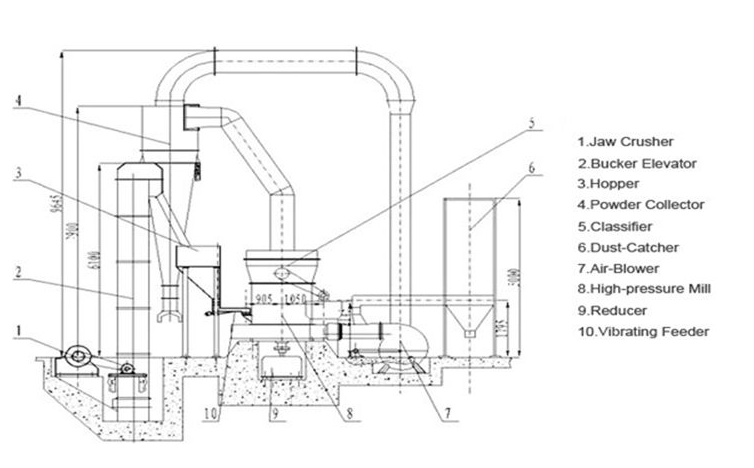

1. After the materials enter the grinding chamber of the main

frame, the grinding roller swings outward and presses closely upon

the grinding ring due to the centrifugal force generated by the

rotation of the main shaft.

2. The blade carries materials to the space between the grinding

roller and grinding ring, and materials are ground as the grinding

roller rolls. After being ground, the powder is selected by

classifier via the cycle wind of the blower and the rough powder

will be back to the grinding chamber for re grinding.

| Model | 5R4119 |

| Particle size of feed(mm) | ≤25 |

| Particle of finished product(mm) | 0.125-0.044 |

| Shift output at different material fine degree | 8--60 |

| Rotate speed of central axis(r/min) | 105 |

| Inner diameter of Pulverizing ring (mm) | 1270 |

| Diameter of Pulverizing roller (mm) | 410 |

| Height of Pulverizing roller(mm) | 190 |

| Main Motor(KW) | Y280s-4-75 |

| Fan motor(KW) | Y250m-4-75 |

| Motor(KW) | Yc200-4-7.5 |

1. The mill is installed on the ground. The ground part is 50% of

the height of the traditional mill.Reduce the height of the factory

building, save the investment of the factory building, more

conducive to equipment maintenance

2. Grinding roller bearing seal is a new type of seal, which is

maintenance-free and oil-free. Eliminate bearing powder, greatly

reduce equipment maintenance costs.

3. The hierarchical cavity adopts suspension structure, which can

automatically lift and shift to reduce equipment resonance, reduce

noise and improve maintenance convenience.